Tech to Tech

- Author: Brian Manley

- Subject Matter: Diagnosis

- Vehicle Application: 1998 Dodge Caravan

- Issue: Intermittent electrical problem

A ’98 Dodge Caravan’s diagnostic cures are deconstructed

With the average age of vehicles on the road in the U.S. around 11 years, it feels as though I’m seeing more age-related issues. One recent example included a 16-year-old minivan that had an intermittent concern of “no dash gauges” and “no start when this happens.” My frustration – and I’m certain you have all experienced this recently – is that I could not duplicate my customer’s concern. I drove the van repeatedly over several days, with no issues. I felt like a detective with no leads. What now?

Unconventional ‘solutions’

One pertinent bit of information my customer gave me is that “When the gauges stop working, smacking the dash sometimes fixes the problem.” Is this a valid clue? Heck, yes! We have all used “smacking” as a valid diagnostic procedure, such as when a starter intermittently won’t crank, or when a CD begins skipping in the vehicle’s player. So where does “smacking” fit into our minivan’s repair process?

A few years ago, I wrote a Tech to Tech article explaining the perils of fretting corrosion: The tendency for some male/female connections to develop excessive resistance over time. So at this point in my career, whenever I am faced with an intermittent electrical issue, I reach for this possibility early on. I know that by simply pulling the instrument cluster out of my customer’s minivan, I can fix the issue. Why? Because fretting corrosion can be temporarily “cured” by disconnecting and reconnecting wires, creating some areas of enhanced electrical contact.

Have you ever “cured” a customer’s concern simply by removing a component and reinstalling it? I would bet you have – and so have I – and it’s a tough “cure” to charge for. Perhaps the following few paragraphs can point you in a new or forgotten diagnostic direction that will give you a concrete explanation of chargeable diagnostic repairs.

Power of collective wisdom

Since I could not replicate my customer’s concern, I turned to one of my favorite resources in this situation: the power of collective wisdom. A search in one of my diagnostic websites revealed several “hits” regarding my customer’s concern and some nice “fixes” that I could investigate. One such hit included a technician who had experienced his 1998 Dodge Caravan with a dashboard that would “die” more often than not, and when this happened he also lost bus communication through his scan tool with the airbag, transmission and body modules. When the dash came back to life, so did these three modules.

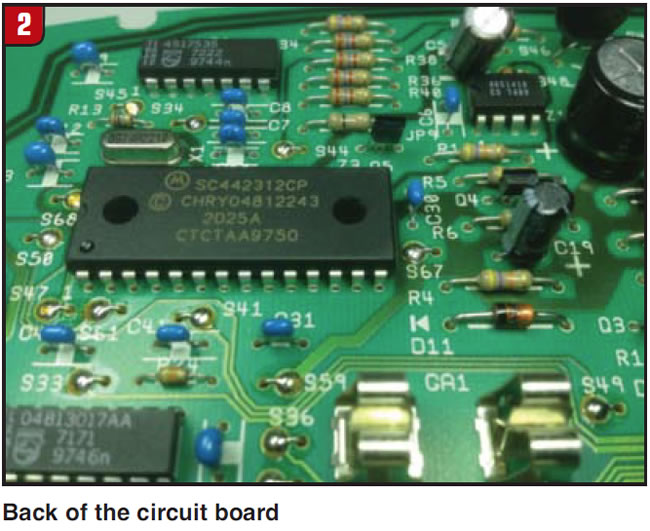

His repair for his Caravan echoed a few others that I found in my investigation: defective cold-solder joints for the pins that host the dashboard connector. He re-soldered the 10 pins for this connector, reassembled and has not had any further issues.

Now, at this stage I believed that my customer was a victim of either high-mileage fretting corrosion or high-mileage fracturing of cold-solder joints. Either way, “smacking” was the big clue that can temporarily solve either of these issues, and I believed I had a good shot at repairing my customer’s minivan, even though I could not get it to act up. At this point in my detective work, I felt like an attorney attempting to prosecute a murder case without the benefit of a murder weapon – or a body. Luckily, there are precedents for convicting when there is no body, just as you and I have repaired a vehicle or two without locating a tangible root cause.

Duplicating the problem

In an attempt to duplicate my customer’s concern, I began disassembling the dashboard with the engine running, hoping to catch my dash gauges failing or my engine stumbling. I gently wiggled wires and twisted plastic parts. When it did not act up, I shut down the engine and removed the instrument cluster.

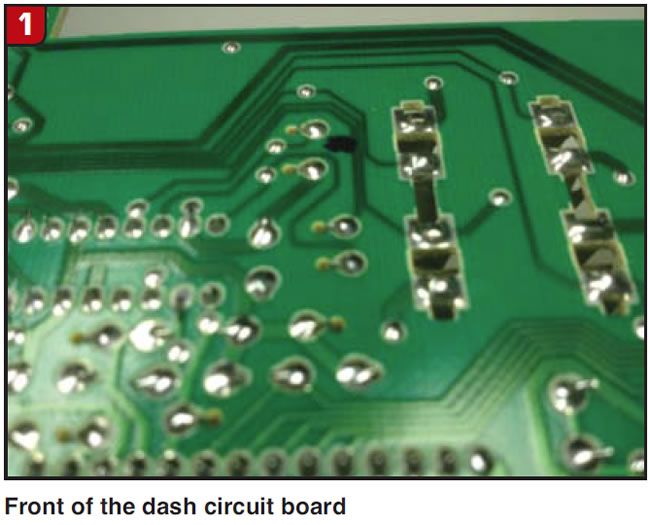

Figure 1 shows the front of my Caravan’s dash circuit board, and Figure 2 shows the back of the board where most of the solder joints reside.

I carefully scrutinized every single solder joint on both sides of this board, and I paid close attention to the pins that mate with the dashboard connector, re-soldering all 10 pins (Figure 3). It is these pins that were identified as the root cause in several case studies that I had found, and I did not like the look of some of my solder joints, so I felt confident in both my research and repair.

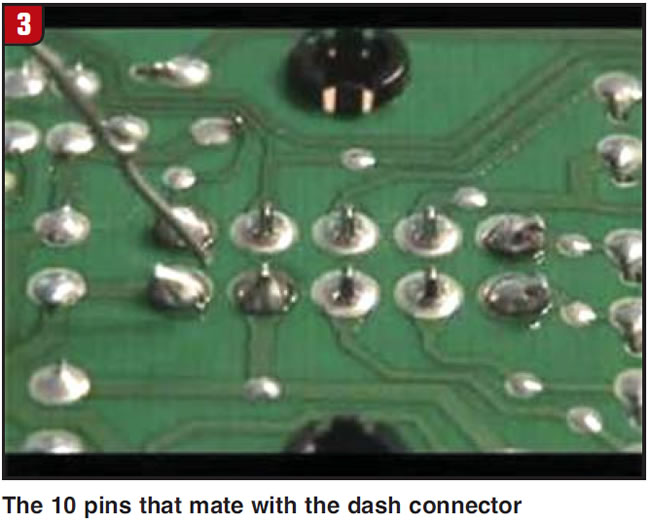

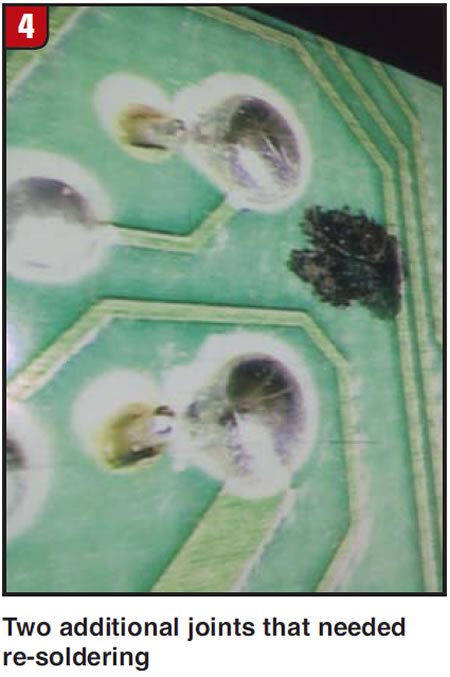

After soldering these 10 joints, I also touched up a few others that looked a little sketchy to me (Figure 4). I reassembled the dash and (still) did not experience my customer’s concern. One “plus” about repairing the original dash is that it eliminates the need for reprogramming a new one with a DRB-III.

Did this repair fix my customer’s concern? To date, my customer says “Yes!” On the basis of my research, I felt confident with this repair – much like an attorney citing precedents for an important case. The combined wisdom of technicians who participate in online repair sites is an invaluable resource, especially when you can’t find “the body.”

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.