Body of Evidence

- Subject: Clearing and relearning shift adapts

- Vehicle Application: Hyundai

- Essential Reading: Rebuilder, Diagnostician

- Author: Jeff Parlee

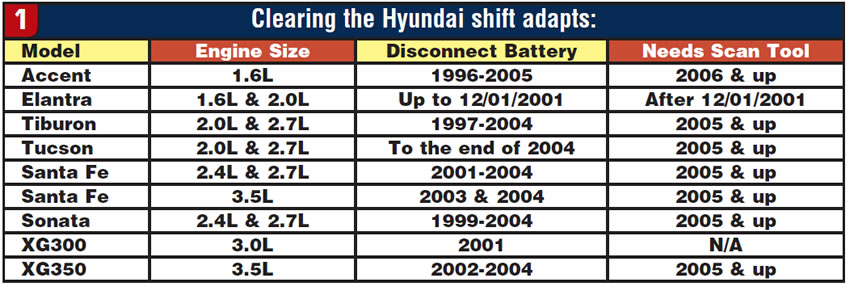

Like most late-model vehicles, Hyundai vehicles need the shift adapts cleared and then relearned to get a properly working transmission after overhaul or valve-body replacement. Some Hyundai vehicles can have the shift adapts cleared by disconnecting the battery, connecting the positive and negative battery cables and turning on the headlights for 10 minutes; others need a scan tool to clear the shift adapts. The chart in Figure 1 shows which vehicles need a scan tool and which can be cleared by the battery-disconnect process. All Hyundai models not shown in Figure 1 need a scan tool to clear the shift adapts.

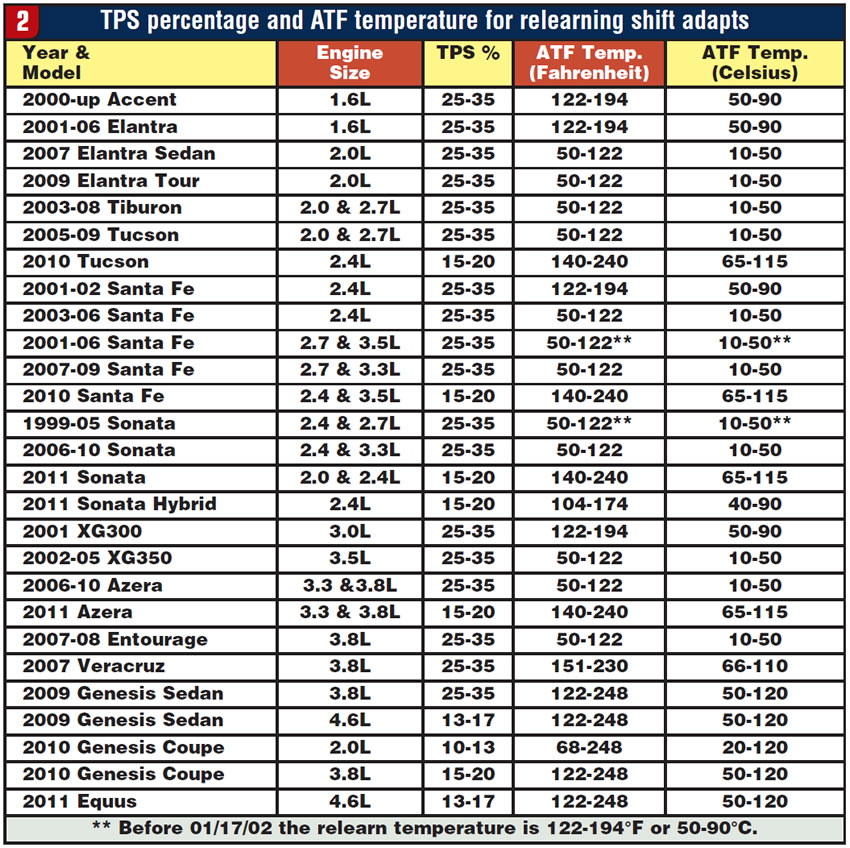

During the relearn process, it is very important that the relearn procedure be done within the temperature ranges and the TPS percentage range for the relearn process to be successfully completed. Some vehicles have a very narrow TPS window and others have a narrow transmission-temperature range that must be adhered to. The chart in Figure 2 shows the TPS and transmission-temperature ranges for each Hyundai vehicle.

Hyundai shift-adapt relearn procedure:

- After the shift-adapt values have been cleared, the adaptive learn procedure must be completed as described below.

- Attach a scan tool to the vehicle to monitor the TPS percentage and transmission-fluid temperature to ensure that the conditions for relearning are met (Figure 2).

- Once the transmission fluid reaches the minimum parameter, accelerate from a stop at the specified TPS percentage, allowing the transmission to shift through all the gears, and then slowly decelerate to a stop. Stop for five seconds. Repeat five times.

- Note: Hold the accelerator pedal steady during all the upshifts.

If additional adaptation is needed, perform the following additional steps:

- Perform several sequential forced downshifts (5-4, 4-3, 3-2 and 2-1) at small to medium throttle openings.

- Perform several forced downshifts (5-3, 5-2 and 3-1) at medium to large throttle openings. With the vehicle stopped and the brake pedal depressed, move the shift lever from P to N to D and back, stopping for three to five seconds in each gear. Repeat five times.

- With the vehicle stopped and the brake pedal depressed, move the shift lever from P to N to R and back, stopping for three to five seconds in each gear. Repeat five times.

Jeff Parlee is director of product support at ValveBody Xpress.