Tech to Tech

- Subject: Transforming a retired patrol car into a drag racer

- Vehicle Application: 2006 Dodge Charger

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Brian Manley

The sheriff now wins more than half of his races

In my previous installment (November 2011), I profiled our progress of “hot-rodding” a part-time sheriff’s car for our local one-fourth-mile drag strip, Bandimere Speedway.

Our speedway hosts a program called “Take it to the Track,” an initiative aimed at getting young drag racers off the street and onto a safer venue, and this 2006 Dodge Charger just needed its exhaust system installed before we could start the engine.

To recap, here is the list of aftermarket, high-performance parts that we were charged with installing:

- A higher-lift roller camshaft and new roller lifters

- A higher-stall torque converter

- A cold-air intake and filter

- A larger throttle body

- Headers and a cat-back exhaust system

- A Diablosport hand-held flash reprogrammer

- A new ring-and-pinion set with a 3.68 gear ratio

- Full engine-gasket set, fluids and filters.

Two months of part-time volunteer labor had been invested in this police car, and we were itchin’ to hear it run!

Figure 1 shows the cat-back stainless-steel exhaust with high-flow mufflers and an X-pipe crossover. My understanding of this type of exhaust crossover is that the “X-type” promotes improved scavenging effect by smoothing out uneven exhaust pulses, whereas the “H-type” crossover is less efficient, as the gases would rather take the path of least resistance, which is straight down the exhaust pipe. I have even read articles comparing these high-performance exhaust systems to no exhaust at all, and often there is no reduction – or addition – in horsepower with the new exhaust, which is pretty amazing!

Once we started the engine, we were greeted with a nice, mellow exhaust rumble, one you could hear from inside the car. It got louder and better with acceleration. Because we had installed non-MDS valve lifters (Our 5.7-liter Hemi engine includes a unique feature – the multi-displacement system [MDS] – that deactivates four of the eight cylinders when the throttle is closed or at steady speeds. This is accomplished through the use of dual-mode lifters and four solenoids that reduce oil pressure from 16 psi to 3 psi to close the intake and exhaust valves on cylinders 1, 4, 6 and 7), we had a permanently illuminated MIL (malfunction indicator lamp). For our purposes, as long as we knew the root cause of the MIL, we weren’t concerned, as this would not affect the intended purpose of our vehicle. I don’t like having this situation; however, I am not aware of a simple way to circumvent this system and make the powertrain control module (PCM) “happy.”

Once I talked our sheriff into letting me test-drive his cruiser, I did so as much as I could! I have to say that everyone else on the road drove extremely well when I was within sight.

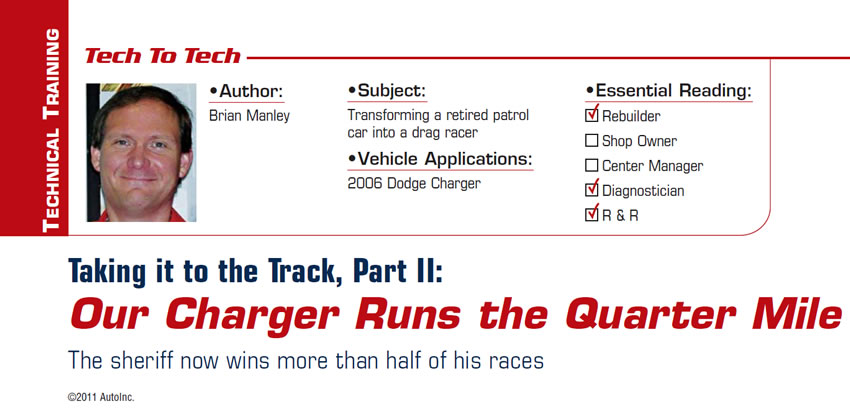

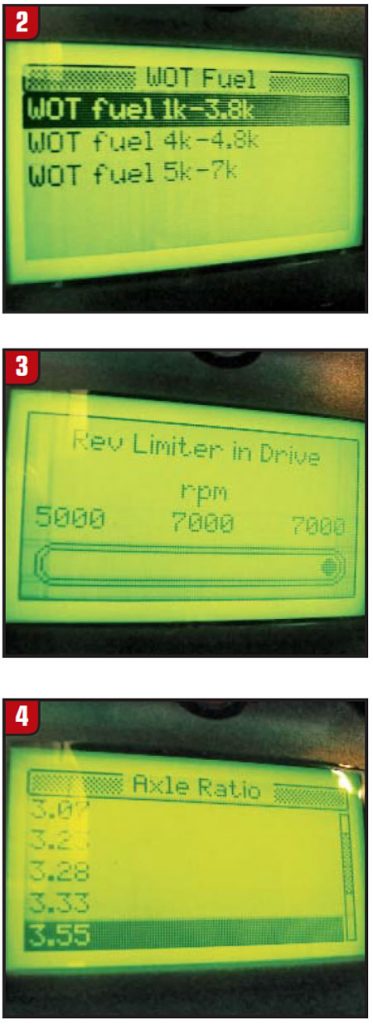

Once I finished having a little fun with my friends and neighbors, I was able to make some adjustments to the PCM with our aftermarket flash programmer. This was my first foray into this style of aftermarket flash programming, and I was excited to see the list of items that I would be able to “tweak”:

- Idle rpm in drive/neutral

- Wide-open-throttle fuel 1K-3.8K/4K-5K/5K-7K (Figure 2)

- Rev limiter in drive/neutral (Figure 3)

- WOT spark 1K-3.8K/4K-5K/5K-7K

- Cooling-fan adjustment

- Tire size

- Axle ratio (Figure 4)

- Shift points

- Shift firmness

- MDS enable/disable

- Transmission control module adaptive reset

I adjusted those that I felt necessary: I raised the rev limiter, increased the WOT fuel and spark, adjusted the tire size to reflect the current treads, changed the axle ratio to the new 3.68 gear ratio and raised the shift points. I only wish I had the time to run a few horsepower pulls on my friend’s Mustang dynamometer, and then adjust individual line items to see what effect it would have on horsepower and/or one-quarter-mile times.

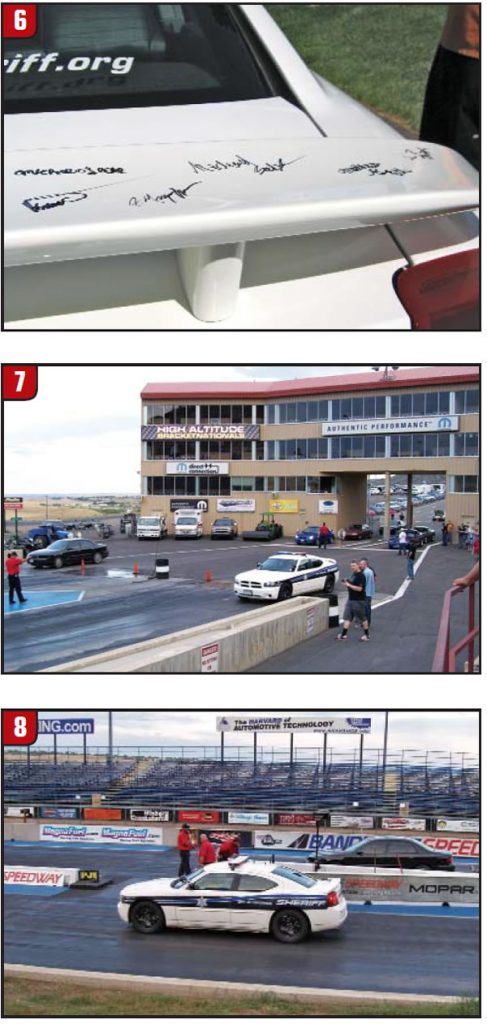

Once we had the Charger running and put some miles on it, the sheriff came to pick it up. He surprised us when he asked all of our young technicians to sign the car’s wing with a permanent marker (Figure 6) – a nice touch for those who donated so many hours to this endeavor.

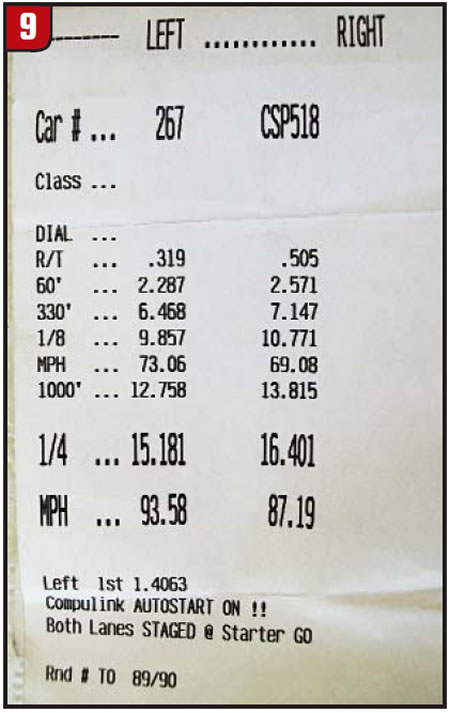

The ultimate test for our race car proved to be the most fun: taking it to the track! We met the sheriff at a test-and-tune night at Bandimere Speedway and proudly watched our car pre-stage, stage and then run a one-quarter-mile pass (figures 7 and 8).

The Charger ran a solid 15.18 seconds and 93 mph (Figure 9). Faster passes would come as we experimented with the flash programmer, and we had a lot of fun racing an eclectic mix of Detroit muscle and import cars.

Conclusion:

As an ASE-certified diagnostic and repair technician, I often use my skills to diagnose no-starts or to R&R clutch assemblies – more-“normal” vehicle repairs. However, this project gave all of us who worked on it a rare opportunity to see what $5,000 of speed equipment can do to a stock Charger. Ultimately, the one-quarter-mile time for our Charger dropped from 15.9 to 14.8 seconds (at 6,000 feet of elevation), and the miles per hour jumped from 87 to 96 at the end of the track.

Our sheriff now wins a little more than 50% of his races – compared with 30% before modification. Plus, he enjoys being more “competitive.” And, the sheriff is happy with the results and has a smile on his face when he leaves the track.

We’re happy for him, and we’re proud we can support such a worthwhile cause.

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.asashop.org or call 800-272-7467.