Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Implications of Mechatronics

- Issues: Diagnostics, computer controls

The purpose, challenges, opportunities

Part 1

For decades, the transmission repair industry has dealt with unending changes, ranging from weight (cast iron versus aluminum cases/components), fluids (natural versus synthetic blends) and sealing components to unit controls/calibrations.

Due to the ’70s oil fiascoes, the push for more gears, lighter units, less torque converter slippage, etc., all to enhance vehicle fuel economy and engine performance, has been growing exponentially over time. Add in a multitude of OE manufacturers and transmission designs, and the aftermarket repair industry has been faced with overcoming various obstacles just to repair a transmission.

The basis of transmission operation is to provide optimal engine RPM and load, which is accomplished via transmission-control strategies. Transmissions of old merely used mechanical/hydraulic components to provide the required shift timing and quality as well as lockup speed and firmness, at least on the earliest models.

Governors, modulators and throttle cables gave way to the age of electrical items such as solenoids, sensors and pressure switches in order to provide a more precise method of operation. Those changes served a purpose back then; however, they fell short of the ultimate goal, which was to provide exacting control of every aspect of the vehicle, from the engine to the wheels.

This article and subsequent articles will cover not only the computerization of transmissions, which has been with us for decades, but more importantly how the Mechatronic approach to transmission operation has been and will continue to be, on an increasing scale, something that the aftermarket repair industry must contend with. Dealing with a transmission that has Mechatronics/TEHCM (transmission electro hydraulic control module) impacts all aspects of repair procedures:

- Diagnostics

- Repair

- Replacement

- Interchangeability

- Programming

Computer controls

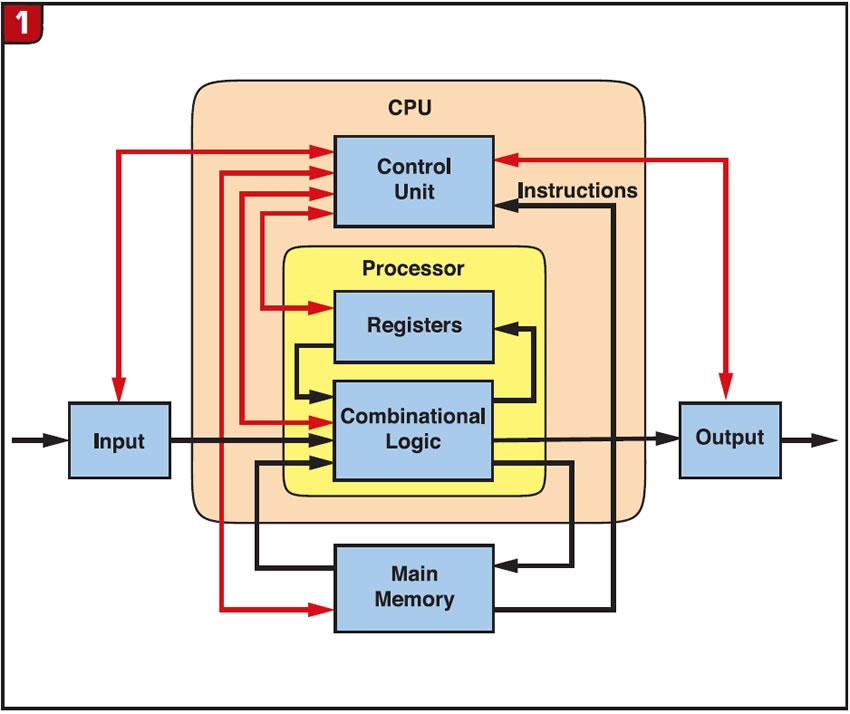

Electrical components aside, overall vehicle operational functions needed to be centralized in order to obtain optimal vehicle performance, therefore approximately 31⁄2 decades ago some relatively basic computers started showing up to control certain aspects of engine and transmission operation. A computer can make the logical, required and consistent decisions as to what to do and crank them out in a nanosecond. A CPU (Central processing unit), which has evolved greatly over time, carries out the fundamental operations that are intended by design (Figure 1).

Figure 1 illustrates a basic CPU arrangement with the black lines indicating dataflow and the red lines indicating control flow. The CPU receives various inputs in order to make the correct decisions. These inputs range from sensors like ISS (TSS), OSS (VSS), WSS / TCS (antilock brake) and cruise control to switches like brake, manual shift or pressure to other CPU’s on the system, relating to transmission operation. There are a slew of other sensors for engine and body controls.

Once a decision is made, commands are issued by the CPU to actuators, such as solenoids, motors or other CPU’s. For instance, the transmission CPU may provide input to the engine CPU to retard performance during a shift. Also, if a problem is detected, a command may be sent to trigger a check engine light to advise the driver of an issue.

Diagnostics have also changed substantially since the early ’80s including the means to test components:

- ALDL: The first hookup for testing was the AL DL (ALCL) (assembly line diagnostic link/communication link) which merely provided a blinking light for trouble codes or, in the case of Cadillac, using the climate-controlled monitor on the dashboard.

- OBD1: By 1990, California mandated better control and testing abilities that were shortly adopted everywhere, so the launch of onboard diagnostics was born. The (1) was added only after OBD11 debuted to denote the earlier design.

- OBD1.5: For a short time (1994-95), an interim system was used on a few models, like Corvette, but was short-lived.

- OBD2: Although OBD2 to was released in 1996 (approaching 20 years ago), it is still the driver of today’s diagnostics, although greatly improved. A major revision occurred in 2008, reference ISO15765-4, which is based upon CAN (controlled area network). The change to CAN provides substantial improvements in speed, operation and manufacturing concerns. OBD2 codes are 4 digits and are prefaced by: B (body), C (chassis), P (powertrain) and U (network). In addition, there are manufacturer and global codes to contend with. All manufacturer diagnostic connectors are now standardized to the J1962 design, although terminal callouts may vary.

- EOBD: Europe adopted the onboard diagnostic standards in 2001 for gas-engine applications and in 2003 for diesel applications. Oh well, better late than never.

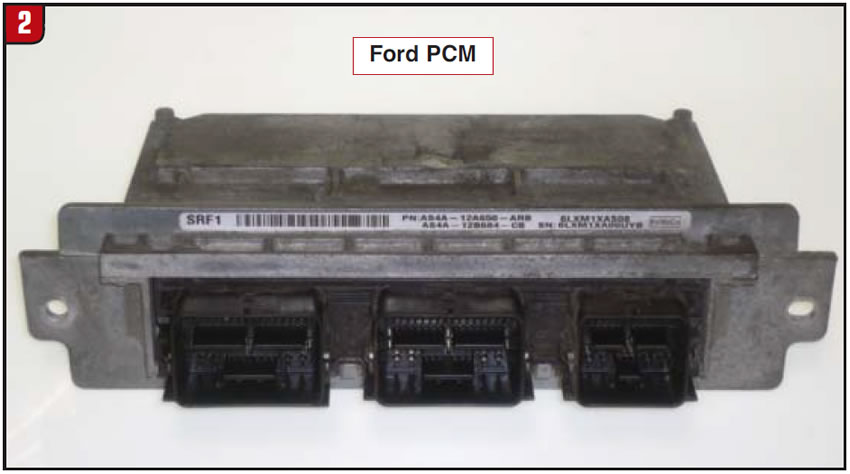

For years, computer functions were all contained in one black box, the PCM, (Figure 2). ECU (ECM) engine controls and TCU (TCM) transmission controls occupied the majority of space and computing activities; however, more stuff was added as time went on. Today, modules (CPU’s/microprocessors) can literally be in every nook and cranny of the vehicle, as is the case of transmissions.

Mechatronics

The whole premise concerning Mechatronics in a transmission is to have the computer functions closer to what they ultimately control. The self-contained arrangement supposedly improves speed and precision as well as manufacturing variables. Not all manufacturers have climbed onto that bandwagon yet. The question is, will they?

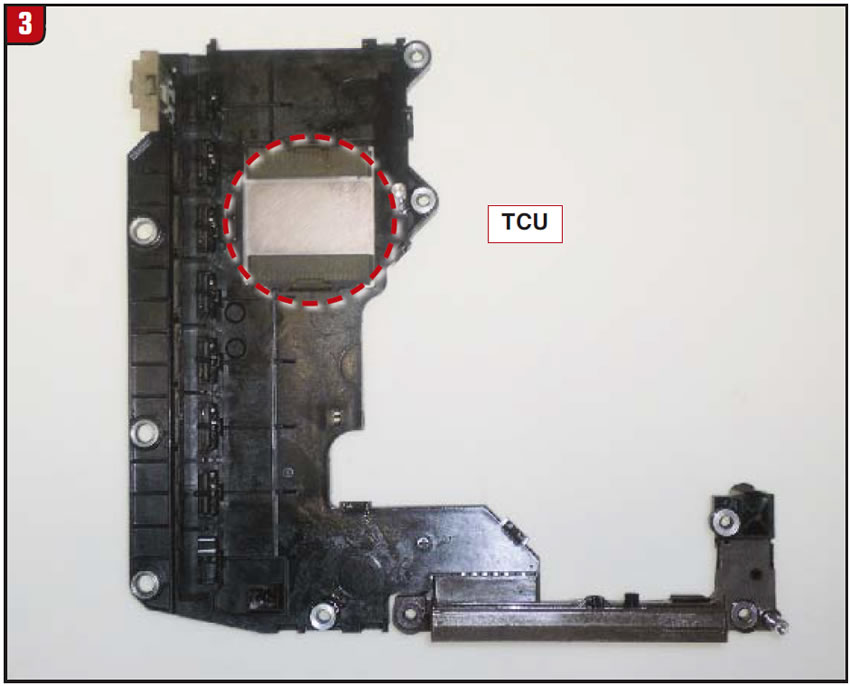

In 2002, ZF, the European transmission producer, released the first true TEHCM in the 6HP family of transmissions, (Figure 3). Although the 6HP valve body resembles other valve bodies, with a lot of solenoids, it is the plastic plate that provides the difference. The TCU is incorporated into the plate, putting the computer functions right next to the solenoids, sensors and switches. Ford followed suit with the 6R60/6R80; however, it removed the TCU from the transmission in certain models in 2010 and put it back into the PCM – go figure.

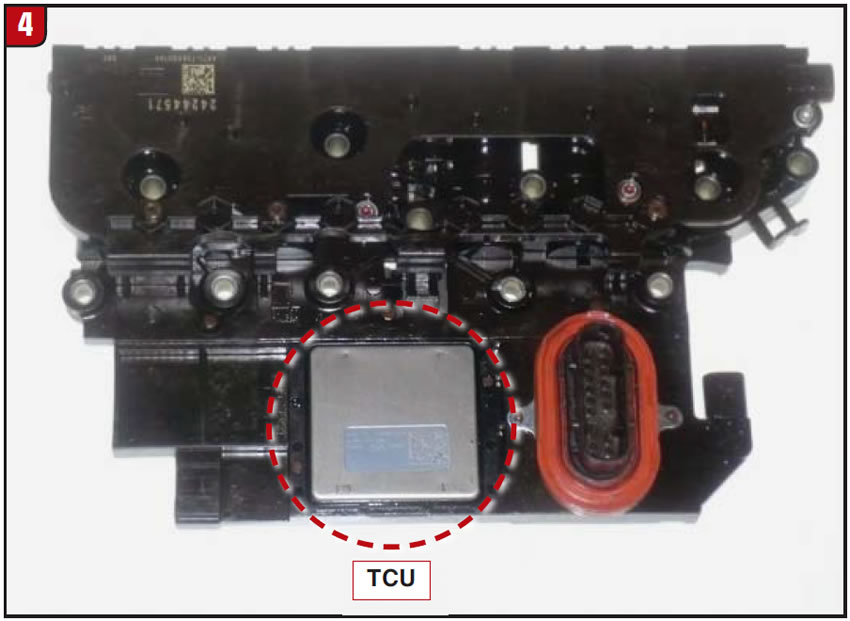

In 2007, when the joint venture 6T70/6F50 units were released, GM chose the TEHCM design (Figure 4), while Ford did not. Engineering opinions do very.

In part two of this series, areas to be covered will be models with TEHCM components, testing abilities, repair capabilities, replacement and reprogramming, as well as available equipment and repair facilities.

Special thanks to William Henny at BLUEREACH Automation for input concerning this article.