With 14 years of being on the road, the Ford 6F35 transmission has a sizeable list of issues requiring repair associated with it. Generation one units are the worst offenders as they have an additional problem to contend with: Ford no longer provides new solenoids for them. This means the hunt for good used solenoids is required when building a unit needing solenoid replacement. This problem is further compounded by locating the correct calibrated band number solenoid. Either that or stick a number 5 in where a number 1 is needed and hope for the best; maybe the customer won’t notice that 2-3 flare.

Oh, and don’t you like the way that #12 driven sprocket needle bearing digs into the case where all that aluminum drops just down below the filter? Then, all those little microns get sucked up and passes through the filter media going directly into the pump taking out the pocket and gear, PR valve and TCC valve bore. Once all these, along with other issues are taken care of, the unit goes out the door.

But wait! You may have sent out a unit destined for failure. Another issue that is essential to address is the integrity of the cooling system. If this is overlooked, the unit can come back cooked.

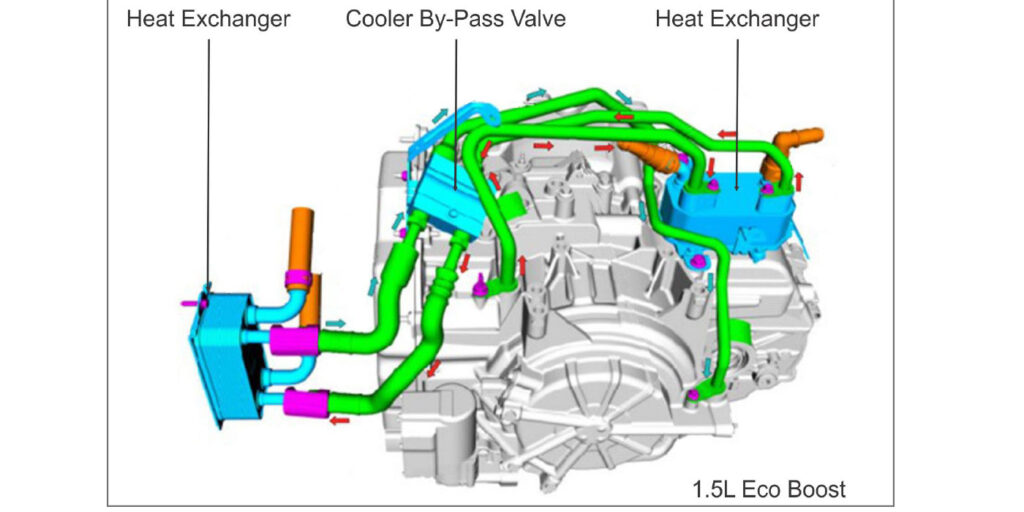

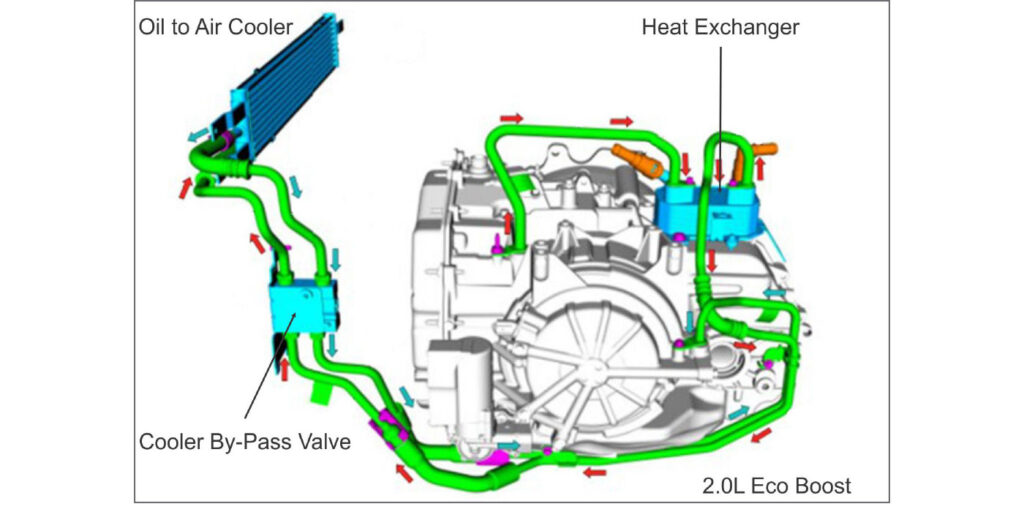

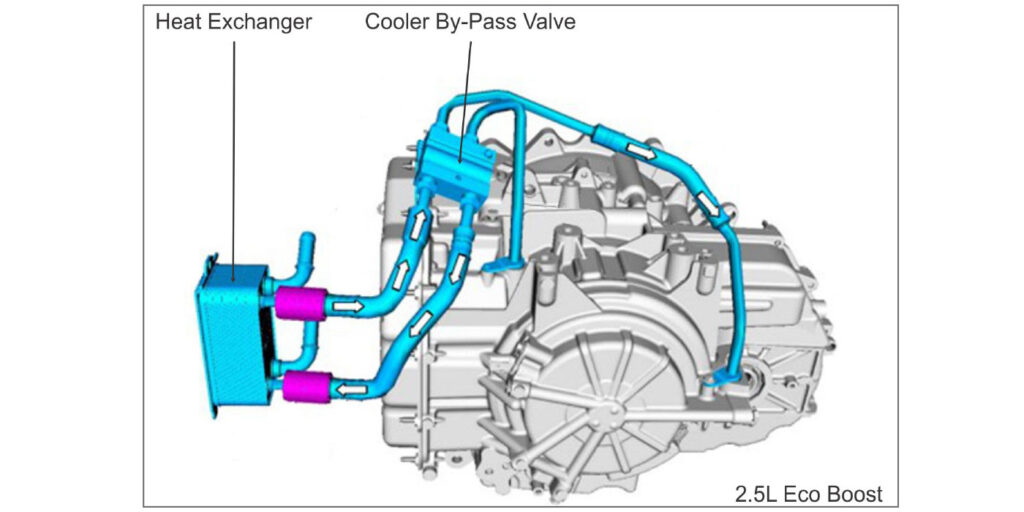

The cooling system varies based on model and engine. Take for example the various cooling configurations found within Ford Fusion vehicles alone. Figure 1 (top of the page) shows the 1.5L Eco-Boost, figure 2 shows the 2.0L while figure 3 shows the 2.5L Eco-Boost application.

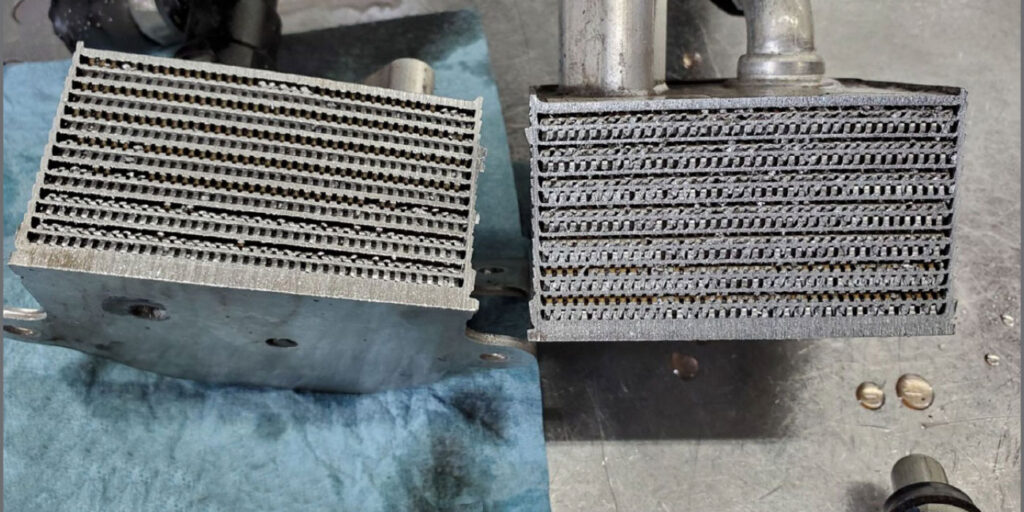

Notice that with the 1.5L Eco-Boost, the Heat Exchanger mounted on a bracket that bolts down to the transmission is the first to receive the fluid coming out of the transmission to be cooled. This means it will be the first component in the cooling circuit to be compromised with contaminated fluid. All types of particulates will get trapped within its tightly mesh webbing as seen in the cutaway provided in figure 4.

If this is not “properly flushed” or replaced, overheating of the fluid will certainly occur along with a lack of cooler flow compromising the lubrication of the transmission’s internal components. And as you can see with the 1.5L Eco Boost in figure 1, there are two of these in the cooling circuit: double jeopardy.

Additionally, there is an external cooler bypass valve fitted in all second-generation transmissions. This assembly is mounted within the cooling lines and its location varies with model of vehicle. This cooler bypass assembly fails miserably and should always be replaced during an overhaul. They are inexpensive to replace, saving you from expensive warranty work.

Figure 5 shows the thermal bypass valve pulled out of its aluminum housing. Notice how dark the fluid is that poured out of this bypass assembly. This is what you will find, but will locate nothing wrong with the torque converter or frictions. The fluid quickly deteriorates due to it not being cooled correctly, which will lead to shifting issues and eventual transmission failure.

And if this were not enough, some applications use a transmission fluid cooler “coolant” control valve and a fluid heater “coolant” control valve as seen in figure 6.

Notice that the word “coolant” is in quotation marks—we did that to catch your attention. These control valves regulate the flow of engine coolant to the heat exchanger. If these valves malfunction, they will compromise the cooling of the transmission fluid by not allowing proper flow of coolant to pass through the heat exchanger.

So, if you don’t properly flush or replace the heat exchanger, replace the cooler bypass valve along and check engine coolant flow after a rebuild, it becomes an expensive risk. It is highly recommended for these checks and services to be an essential part of the repair process to prevent it from coming back on a hook cooked.

Read the full archive of TD‘s Technically Speaking column here.