Technically Speaking

- Author: Mike Riley

- Subject Matter: 9-speed transmission

- Unit: ZF9HP48

- Issues: Noteworthy features

So far, the leading entry for the “Schwinn Got Gears 10-Speed” contest is from the German transmission manufacturer ZF. With the release of the ZF9HP48 (Chrysler 948TE) FWD nine speed, ZF has edged out the other guys, at least for the moment. Supposedly, a grand champion 10 speed is just around the corner, and won’t that be wonderful.

All of this calls into question, why the push for more transmission speeds? At some point, there is a diminishing return on investment for multiple gears or ranges. A 20 speed would do little more than a seven- or eight-speed unit outside of the lab. Any fuel economy gain can be offset by a drivability or durability loss. Part of this approach is bragging rights, as in look what we have and you don’t.

In the past, more speeds meant more iron (clutches, planets, gears, valves, etc.); however, with advancements in electronics and design structures, additional speeds have been obtained with fewer components as with the ZF 8HP family of transmissions. The 9HP48 is yet another example of out-of-the-box thinking.

In mid-2013 Chrysler and Jeep started to use the 9HP48, until the Chrysler transmission plant in Kokomo ramped up with the 948TE. Although the basics are the same, parts are not interchangeable necessarily, so be sure of the model of unit in a particular vehicle before ordering replacements. Other vehicle manufacturers have also started to use the nine speed, such as Acura/Honda, Fiat and Land Rover.

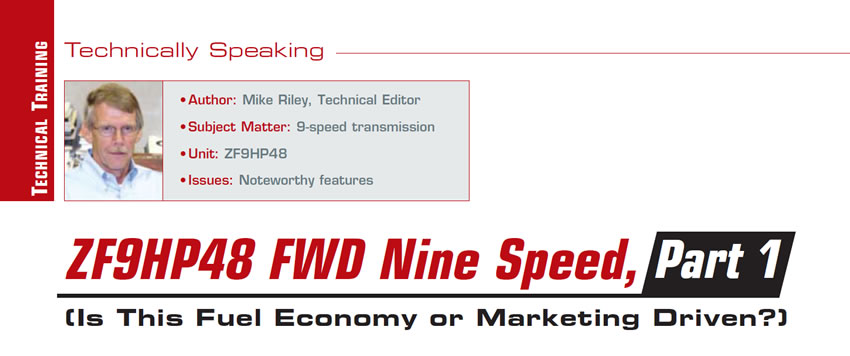

The 9HP48 is an extremely compact transmission considering what it does (Figure 1). Like other FWD transmissions, the 9HP has a bell housing, case, and valve body cover. There is no bottom pan, which means that the filter is not accessible externally. Although there is no end cover, there is an oil passage cover that has a bonded steel gasket underneath. There is also an external hydraulic line at the back of the case that could blow out with age. Unlike the 8HP family, the 9HP is not a mechatronic design. The TCM does bolt onto the outside of the case. The 9HP uses a torque converter; however, a hybrid version, the 9P48H, will utilize an electric motor instead. The unit is just shy of 200 lbs. There is a bar-code label on top of the case to denote model info. The 9HP can be equipped with a mechanical or electronic pack arrangement.

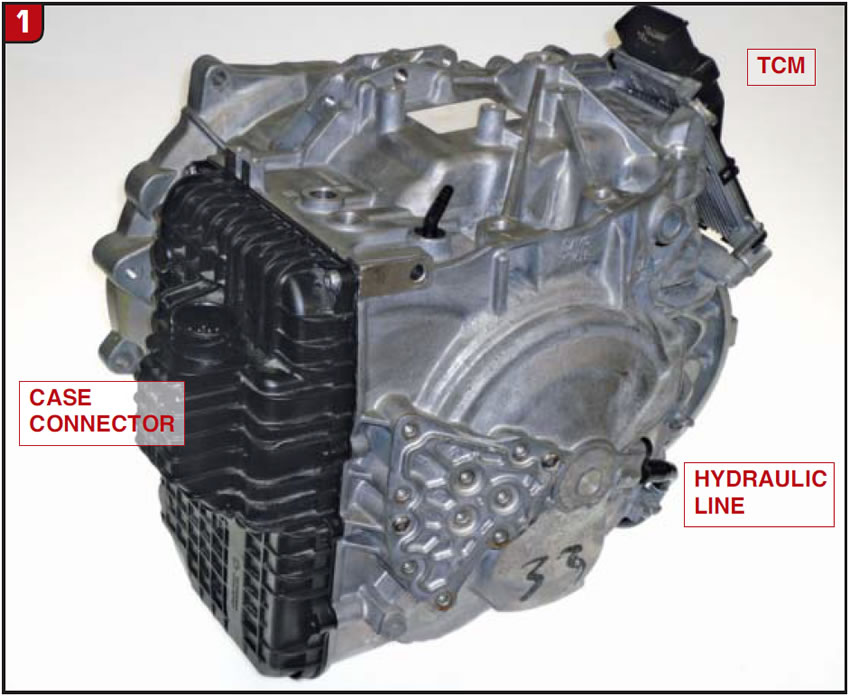

The TCM can be bolted onto the case in different position based upon model. There is a multiprong connector and the TCM has four bolt holes (Figure 2). Markings on the TCM can be by Chrysler, ZF or others depending on the vehicle. There has already been several reprogram/relearn updates to address certain issues, so ensure that all have been performed before doing any repairs.

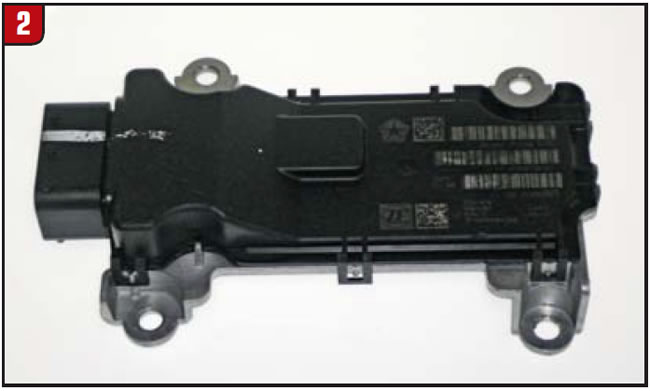

The valve body side cover is a ribbed plastic design and has a molded spaghetti seal between the case (Figure 3). The electrical case connector extends through a hole in the cover and is directional. A unique feature is the hold down bolts, which are crimped into the torque limiters. The assembly pushes into the cover holes.

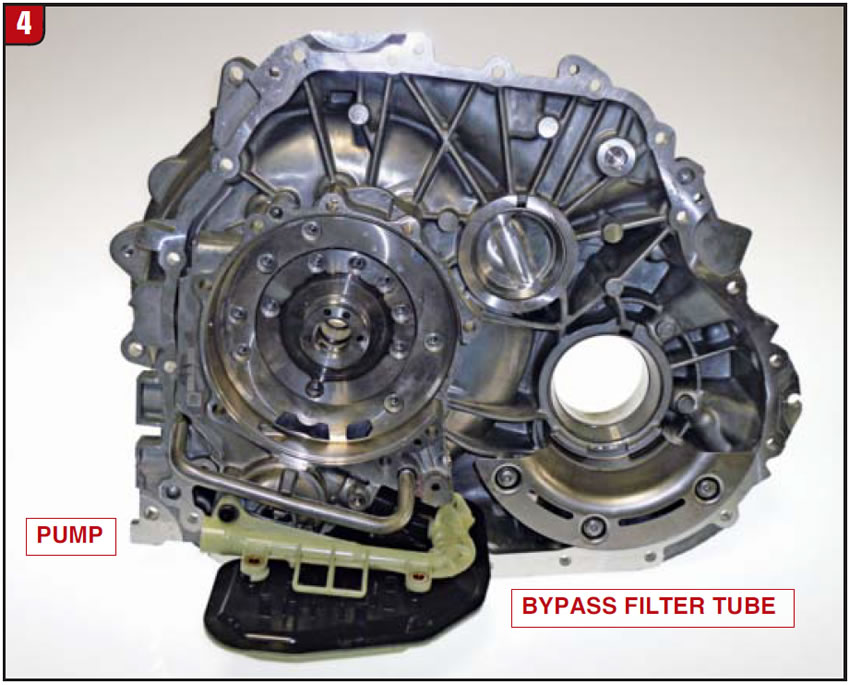

With the cover and valve body removed, the bell housing can be split from the case. The TC hub rides in a bearing, not bushing, and the TC seal is held in by a snap ring. The inside of the bell housing is where the remote axis pump housing, stator support and filter assembly are positioned (Figure 4). There is also a differential shroud and bearing race as well as the transfer gear bearing race. The bell housing to case gasket is a rubber-coated steel design.

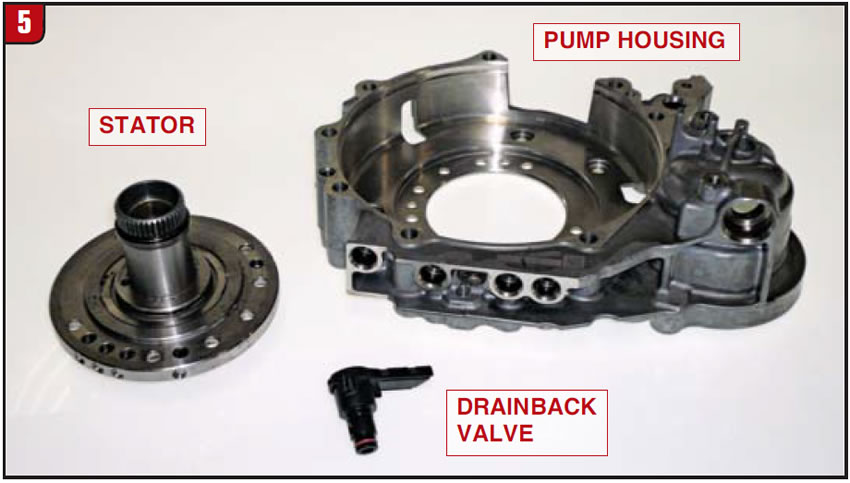

The stator support is merely a flanged support that bolts to the bell housing. The sealing rings seal the “E” clutch assembly. The pump housing contains the chamber for the remote pump as well as having several holes for the valve-body connecting tubes (Figure 5). There is also a hole at the base of the housing for a spring-loaded drain back valve. The pocket around the stator support is for the “E” clutch drum.

The filter design is rather unique due to the 9HP start-stop capability. Instead of having an auxiliary pump as many manufacturers use or the HIS (hydraulic impulse system) design that ZF uses for the 8HP, the 9HP utilizes a filter bypass tube in order to provide an immediate charge of pressure upon restart (Figure 6). Only one clutch element is needed to reapply, which is by design. The bypass tube connects from the valve body to the outlet of the filter, which is made by Filtran, and both pieces use O-rings. The filter outlet neck fits into the pump housing.

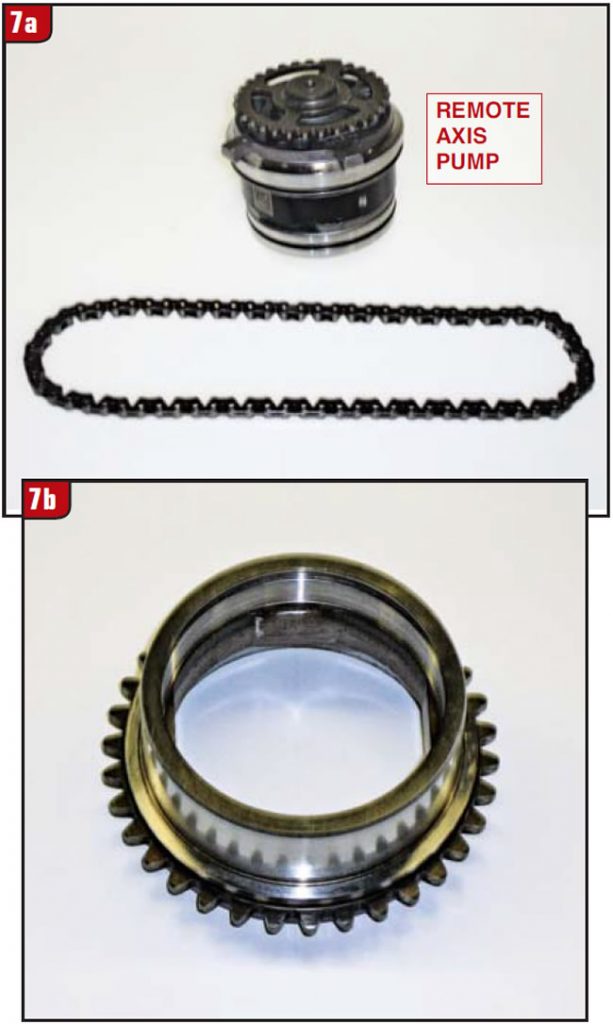

As stated, the pump is a chain-driven remote axis pump, similar to the 8HP pump (Figure 7A). The pump is a dual-chamber vane type and is positioned at the base of the pump housing. The 9HP pump is small but mighty and can churn out the volume of oil when needed. The chain is also similar to the 6T70, so always check for wear. The pump body uses two O-rings. The drive gear has four flats that mesh with the converter hub (Figure 7B).

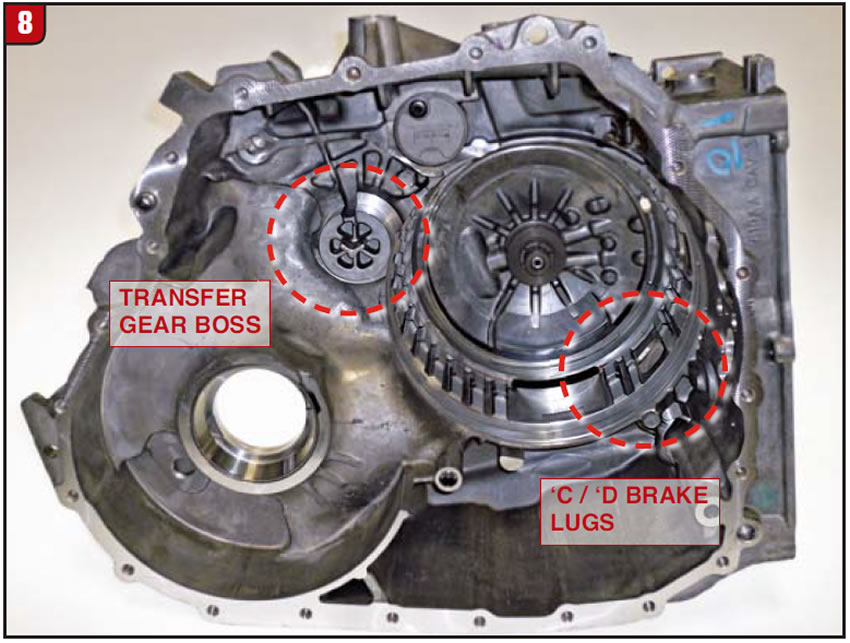

The inside of the case is fairly basic. There are two sets of case lugs that spline to the “C” and “D” brake steels as well as the piston pockets (Figure 8). At the bottom of the housing is a steel sealing-ring support that is pressed into the case. There is also the park rod cam that bolts in. Before the “D” piston housing can be removed, the transfer gear bearing must be pulled off of the case boss. In addition, there is a tube seal that fits between the case and bell housing that must be replaced. The valve body surface contains cutouts for the input/output speed sensors, connecting tubes and shifter components.

The friction brake at the bottom of the case is the “C” brake. The frictions/steels are applied by an aluminum piston and have a Belleville spring for release (Figure 9). The frictions are the segmented (button) design and the backing plate has dimples to prevent the snap ring from popping out. The “C” brake is applied in 2nd, 6th & 8th gear.

The “D” brake is in front of the “C” brake and is held in place by the piston housing. The piston is also aluminum and uses a Belleville spring that rest against the case lugs (Figure 10). The frictions are also the segmented design. The “D” brake is applied in park/neutral, 1st & 7th through 9th gears.

Thanks to the folks at TransTec for providing the transmission and related information in this article.