Issue Summary:

- This month’s Tech/Talk covers a variety of complaints and fixes, leading off with a Saturn that moves forward in all gear selections. The problem is caused by a mismatch of the manual valve and manual-valve link.

- A missing rubber-coated sleeve in the overdrive-servo assembly of a 4R70W may result in burned forward clutches.

- Torque-converter discoloration in a 4T60-E may be caused by a melted plastic spring retainer in the to-cooler fitting.

- A weak or collapsed 4th-apply piston return spring in 4L60 and 4L60-E units may be the cause of burned 2-4 bands.

- We also have information on a Subaru Justy ECVT that has no ratio change from low.

- Mismatching manual valve to case in G4A-EL units will result in either no reverse or movement in neutral. Mismatching reverse and forward drums will cause stacked shifts.

- A complaint of no movement in any range on a Subaru RE4-style transmission may be caused by an incorrectly installed lockup-control valve and spring.

- Shift-solenoid and lockup-solenoid wires that are connected backward on Mazda MPV R4A-EL units will produce a 1-3 upshift in Drive.

Issue:

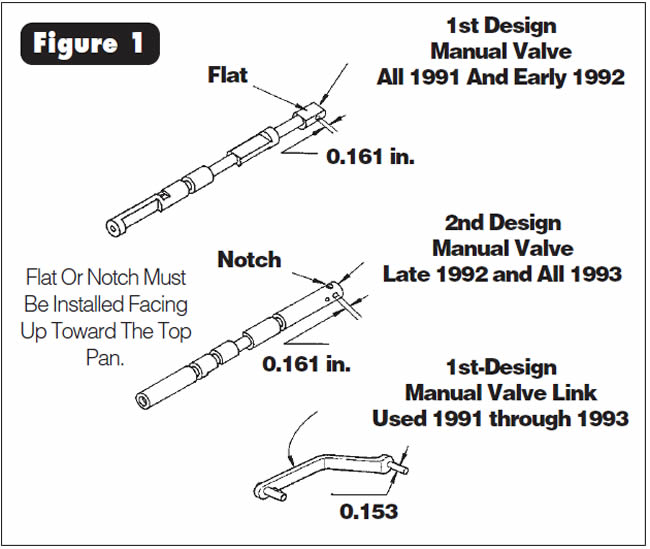

The three different design levels of the manual valve and two different design levels of the manual-valve link can create complaints of reverse and/or forward movement with the selector in Park or Neutral if they are installed incorrectly and/or parts are mismatched.

Complaint 1:

Late-1992 and all 1993-model transaxles with the 2nd-design manual valve – The vehicle moves forward in all selector-lever positions including Neutral and tries to move forward in Park.

Complaint 2:

1993/1994 transaxles – The vehicle tries to move forward and/or backward with the selector lever in Park and can move unexpectedly forward and/or backward with selector lever in Neutral.

Cause 1:

- 2nd-design manual valve installed improperly, with the notch facing down toward the case. The notch must face up toward the top pan (See Figure 1).

Cause 2:

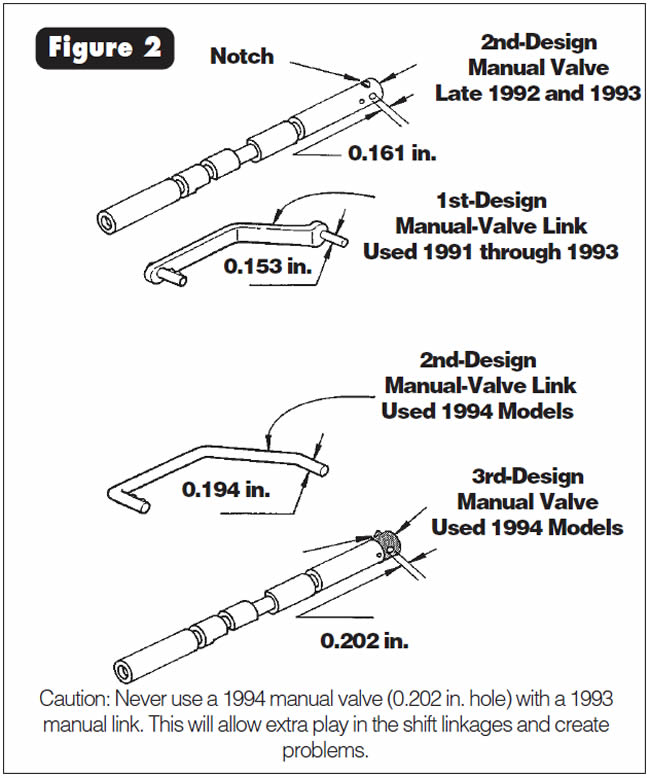

- 1994 (3rd-design) manual valve used with a ’91-93 stamped-form manual-valve link that allows extra play in the shift linkage because of mismatched parts. See Figure 2 for dimension differences.

Correction 1:

- On all 1991-93 models, remove the valve body and orient the manual valve with the flat (1st design) or notch (2nd design) on the manual valve facing up toward the top pan (See Figure 1). Re-install the valve body and torque to proper specifications.

Correction 2:

- Install the manual-valve link of the proper design level with the matching manual valve.

Functionally, the 1994 (3rd-design) manual valve is the same as the late-1992 and 1993 (2nd-design) manual valve. There are two different stem diameters on the manual-valve link where it goes into the manual valve.

The 1st-design stamped-form manual-valve link is used on all ’91-93 models, and the stem diameter is 0.153 in. (See Figure 1).

The 2nd-design one-piece wire manual-valve link is used on all 1994 models, and the stem diameter is 0.194 in. (See Figure 2).

As a result of the change to the manual link, the hole in the manual valve also had to increase in diameter from 0.161 in. to 0.202 in. to accommodate the 2nd-design manual-valve link (See Figure 2).

A plastic cap also was added to the 1994 (3rd-design) manual valve as an assembly aid to prevent the manual valve from being connected to the manual-valve link backward (See Figure 2).

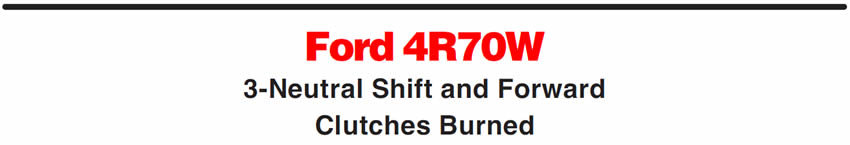

After overhaul, the 4R70W transmission has a 3-neutral upshift, and upon disassembly you find the forward clutches burned.

The cause may be an incorrectly assembled over-drive-servo assembly, with the rubber-coated sleeve omitted. The 4R70W transmission is calibrated with a smaller-diameter overdrive-servo piston than is the AODE transmission. To retain a common case between the two transmissions, an additional rubber-coated sleeve is required on the 4R70W overdrive-servo assembly (See Figure 3).

Install the rubber-coated sleeve in the overdrive-servo assembly (Refer to Figure 3). If the sleeve is missing or lost, you must buy the complete over-drive-servo assembly, available under OEM part number F3LY-7H188-A. The rubber-coated sleeve is not available individually.

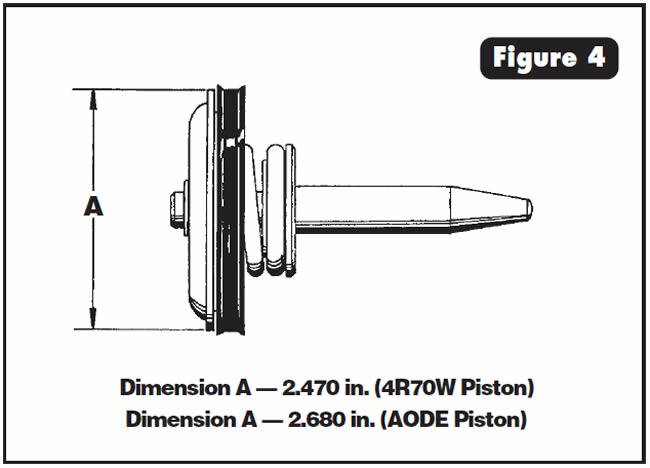

Figure 4 shows dimensions of the two different overdrive-servo pistons to help you distinguish between the two.

- 4R70W Overdrive-Servo Assembly (Includes Sleeve) ..F3LY-7H188-A

- AODE Overdrive-Servo Assembly…………F2VY-7H188-A

Some 1991-94 vehicles equipped with the THM 4T60-E transaxle may display a torque converter that has turned blue or black.

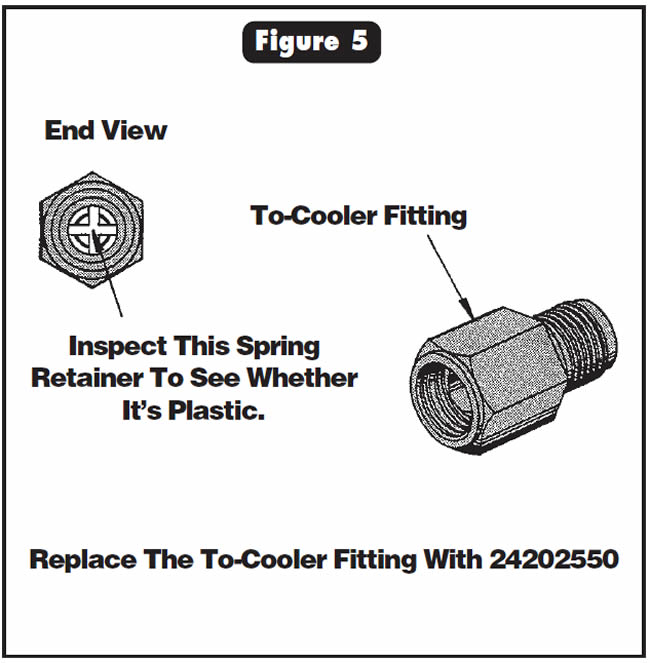

The cause may be that the plastic spring retainer inside the to-cooler (large) fitting has melted and is blocking or restricting cooler flow.

Remove the to-cooler (large) fitting and inspect the spring retainer inside the fitting (See Figure 5). If the spring retainer is melted, replace the fitting with OEM part number 24202550, which has a steel retainer.

Replacing the to-cooler fitting is advisable, even if the plastic spring retainer is not melted.

If the spring retainer is melted, the cooler in the radiator needs a thorough flushing and possibly replacement.

- Cooler-Line Fitting (Steel Spring Retainer) …………24202550

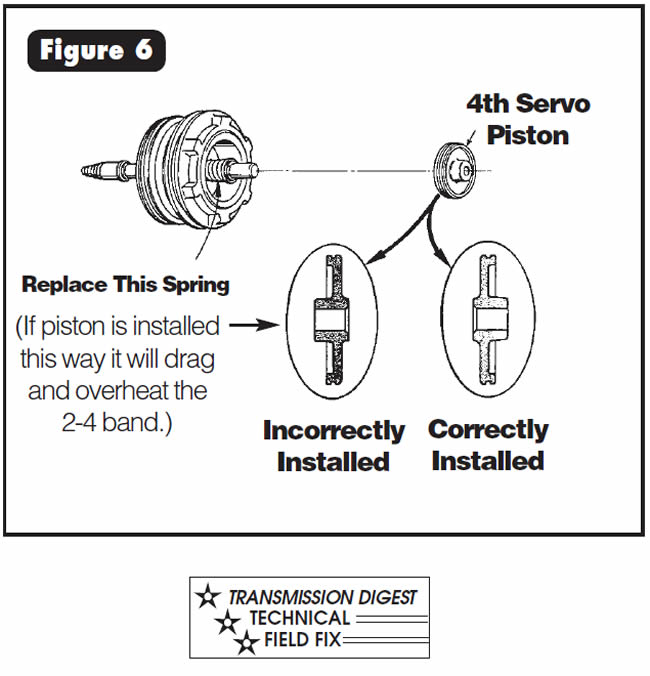

Repeated and/or premature burning of the 2-4 band assembly with nothing else in the transmission showing any signs of burning.

The cause may be a weak or collapsed 4th-apply-piston return spring on the servo-apply pin that will not allow the band to release fully on a 4-3 down-shift.

Compress the spring on the bench, while it is still installed on the servo pin, and hold compressed for about 30 seconds. Release the compression and check for back-and-forth servo-pin movement in the piston assembly. If there is servo-pin endplay, the spring needs to be replaced.

Remove and discard the OEM spring from the servo-apply pin. Replace the 4th-apply-piston return spring with part number K004, available through Shift Technology Products. Re-install washer and E clip (See Figure 6).

Transmission remains in low; will not change ratio.

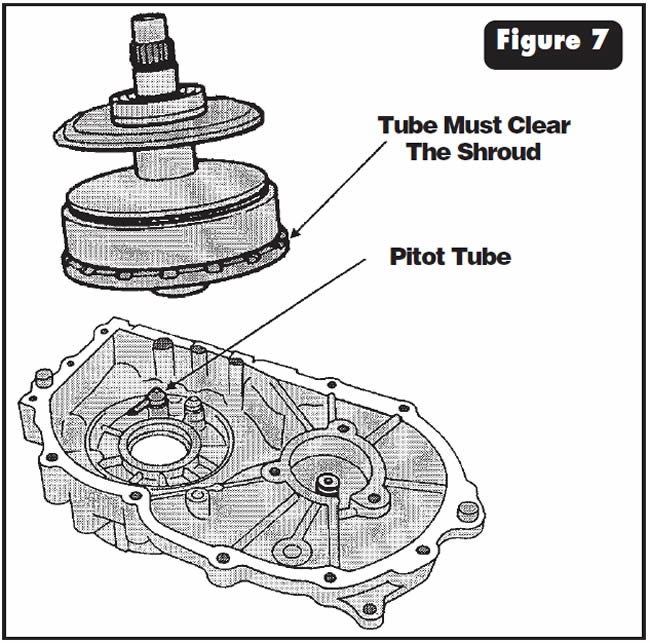

Failure to rotate the pitot tube out of the primary pulley before splitting the side case and the transmission case will cause the pitot tube to break or bend, causing a loss of pitot pressure necessary for a ratio change (See Figure 7).

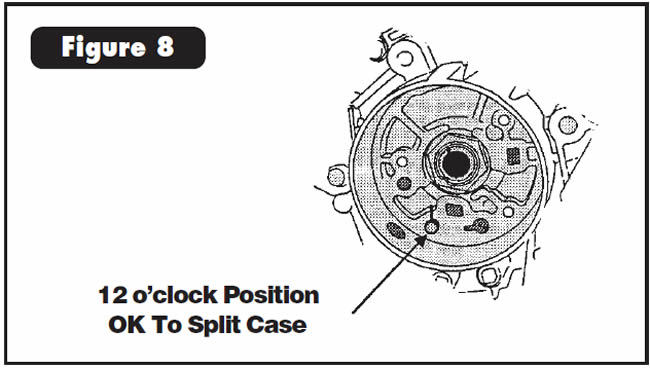

After removing the pump, reach into the pump cavity and rotate the pitot shaft until the pin in the end of the shaft points to the 12 o’clock position. Then you can split the case halves safely

(See Figure 8).

When reassembling the case halves, be certain the pitot-shaft pin is at the 12 o’clock position.

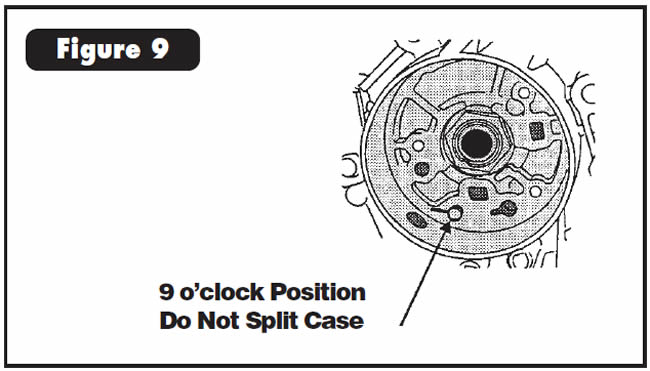

Once you have fastened the case halves together, rotate the pitot shaft so the pitot-shaft pin is at the 9 o’clock position (See Figure 9).

When the pitot shaft is in its correct assembled position (9 o’clock), the pin in the end of the pitot shaft will fit into its cavity in the pump assembly.

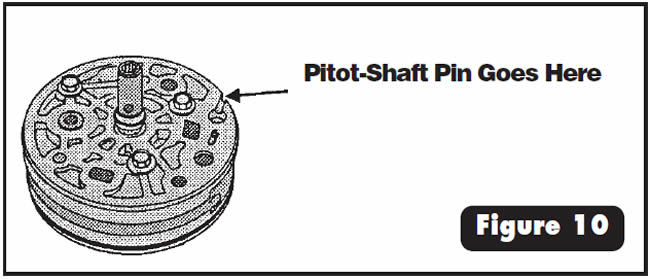

(See Figure 10).

Vehicles equipped with G4A-EL transaxles may exhibit no reverse, movement in neutral, or a sensation of two ranges being applied at the same time or a bind-up on engagements or upshifts after replacement of the valve body or rear case half.

The cause may be a mismatch of the manual valve and case.

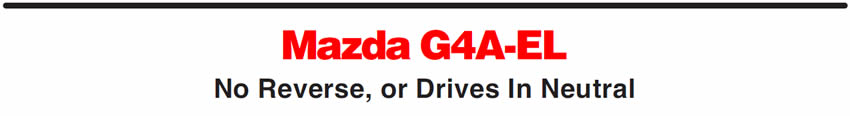

To help you match the parts correctly, Figure 11 provides the dimensions of the manual valves and rear cases for the 2.2L non-turbo and the 2.2L turbo and 3.0L models. Install the proper manual valve for your application.

No movement forward or backward on the ground. On the lift, the wheels may move forward or back-ward under heavy acceleration.

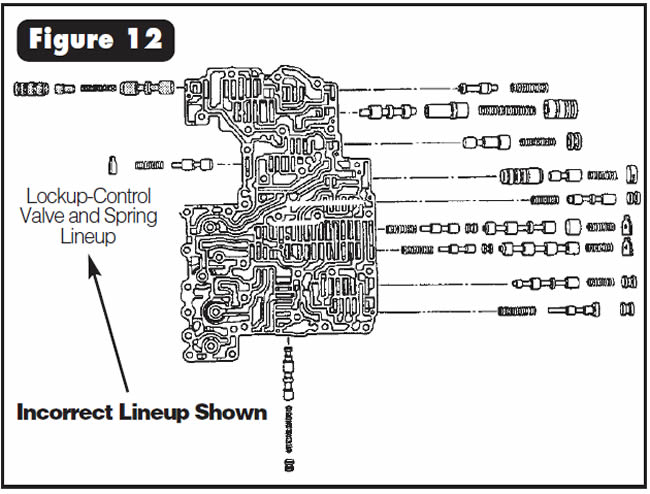

One cause may be that the lockup-control valve and spring were installed incorrectly into the valve body during overhaul (See Figure 12).

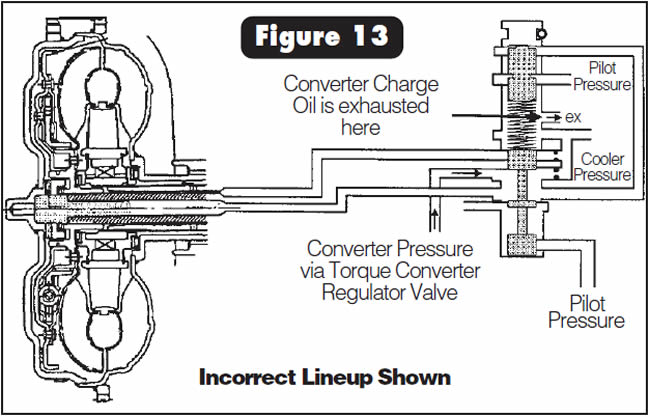

With this valve and spring installed backward, converter-fill oil is exhausted through a passage in the valve body (See Figure 13).

Note:

Some manuals show the valve-and-spring lineup incorrectly.

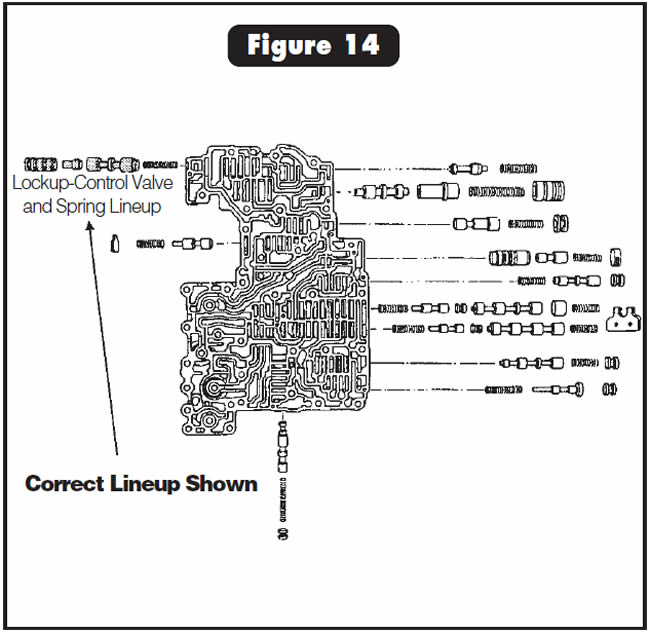

To correct this problem, install the lockup-control valve and spring correctly into the valve body during assembly (See Figure 14).

Vehicles equipped with F4A-EL or F4EAT exhibit what seems like a 1-3 upshift in the Overdrive or Drive range after overhaul.

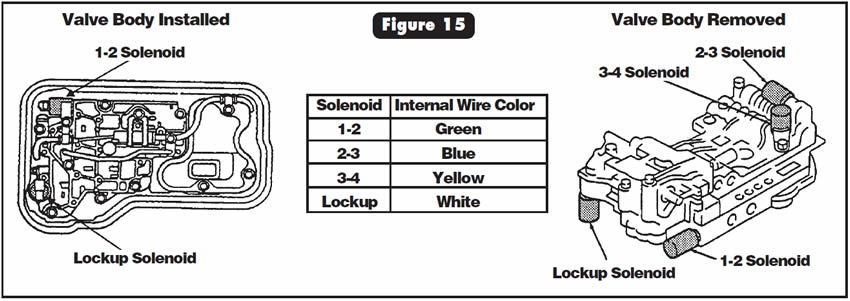

The cause may be that the 1-2 shift-solenoid wire was placed into the lockup solenoid and the lockup-solenoid wire was placed into the 1-2 shift solenoid. Connecting the solenoids backward produces a 1-lockup-3 upshift.

Refer to Figure 15, which shows the locations and wire colors of the solenoids, to identify and connect each solenoid correctly.

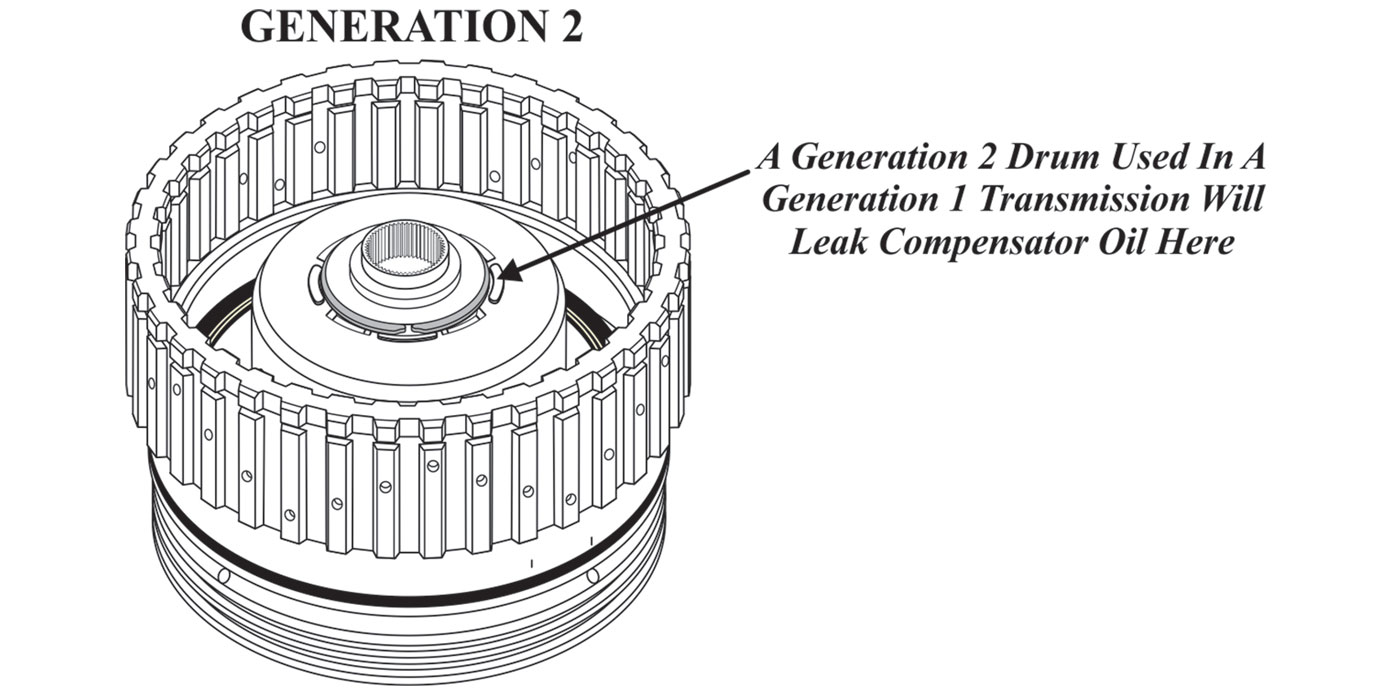

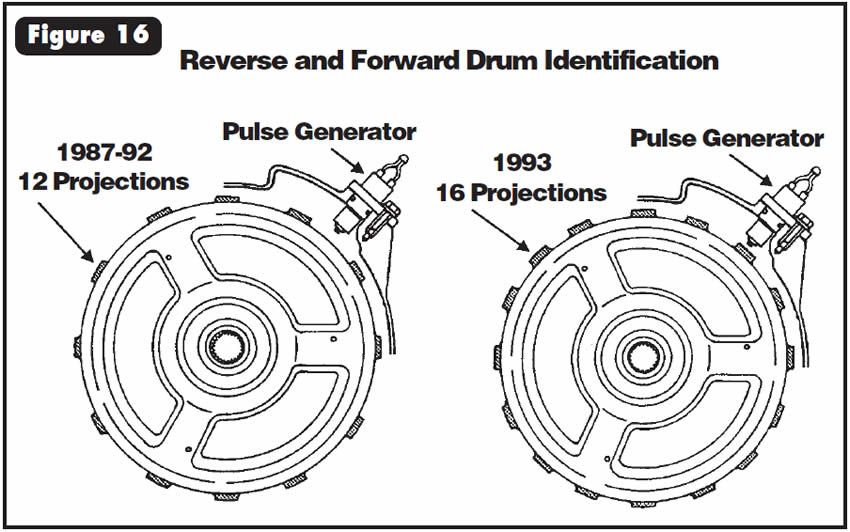

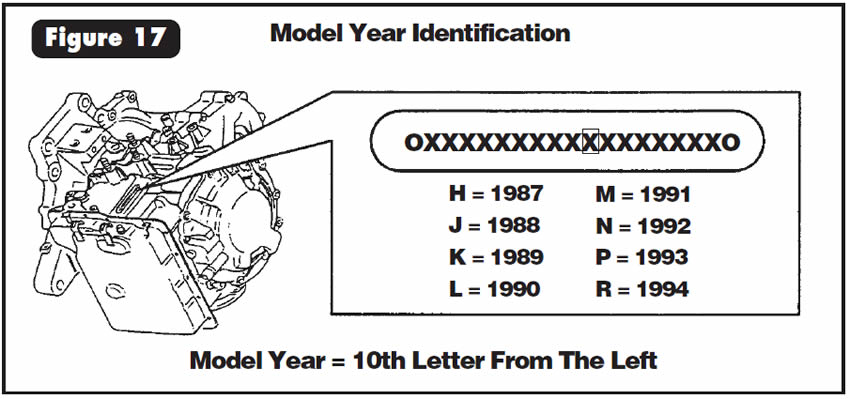

After overhaul, vehicles equipped with G4A-EL transaxles may exhibit early or stacked shifts with converter-clutch apply by 20 mph, without storing any trouble codes.

The cause may be that a 1993 reverse-and-forward drum was installed into a 1987-92 vehicle.

1987-92 reverse-and-forward drums have 12 projections. 1993 reverse-and-forward drums have 16 projections (See Figure 16). These projections stimulate the pulse generator, which converts drum or turbine speed to AC current that is sent to the ECAT (electronically controlled automatic transmission) computer. Installing a 16-projection drum into a 1987-92 vehicle will cause the drum- or turbine-speed signal to indicate a faster speed, which may change shift strategy.

Refer to Figure 17 to identify the model year, and install the proper drum for your application.

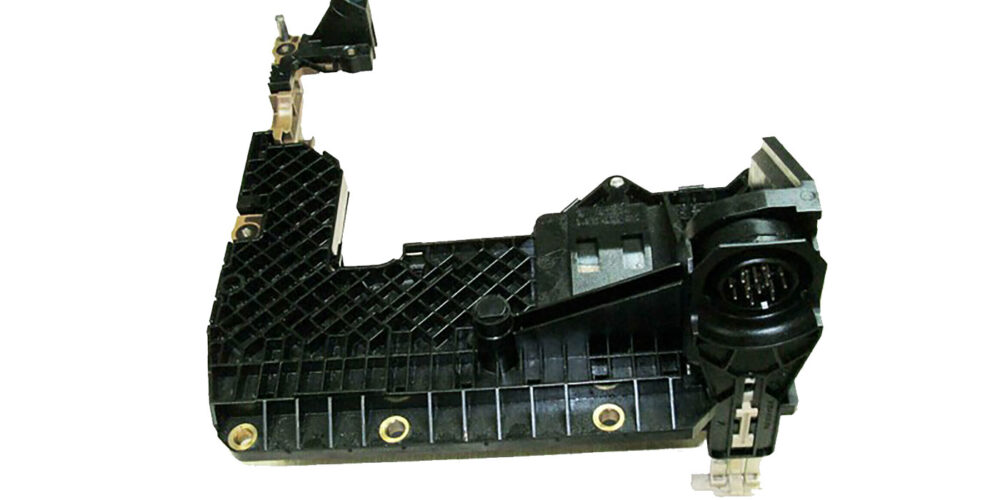

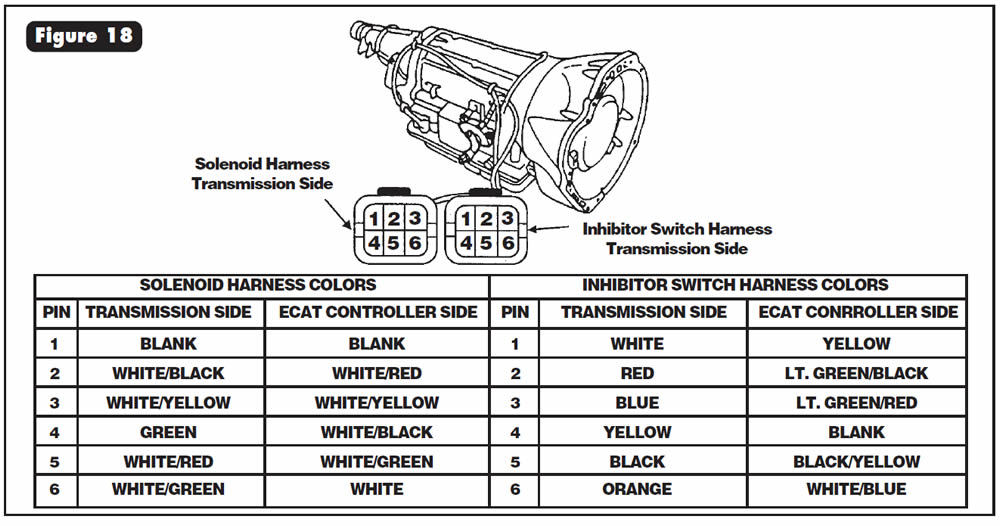

After overhaul on early-model MPVs equipped with R4A-EL transmissions, the vehicle exhibits 3rd-gear starts in the Drive range, and the Hold light is flashing continuously.

The cause may be that the computer-side shift-solenoid harness was connected to the inhibitor switch and the computer-side inhibitor-switch harness was connected to the shift solenoids. This will result in no voltage sent to the shift solenoids and a 3rd-gear start in the Drive range. This also will result in trouble codes being stored and causing the Hold light to flash, because the ECAT control unit now will see open circuits at the solenoid wiring harness.

See Figure 18 to identify common wiring colors of the inhibitor-switch and solenoid correctly, and switch the computer-side connectors to cure the problem.

October 2000 Issue

Volume 17, No. 10

- Saturn: Moves Forward in All Gear Selections; Moves Backward and/or Forward in Park or Neutral

- Ford 4R70W: 3-Neutral Shift and Forward Clutches Burned

- THM 4T60-E: Torque Converter Discoloration

- THM 4L60 AND 4L60-E: Burned 2-4 Band Only

- Subaru Justy ECVT: Low Ratio Only; No Ratio Change

- Mazda G4A-EL: No Reverse, or Drives In Neutral

- Subaru RE4 – Style Transmission: No Movement In Any Range

- Mazda F4A-EL/F4EAT: Upshifts 1-3 In Drive

- Mazda G4A-EL: Stacked Shifts

- Mazda MPV With R4A-EL: 3rd-Gear Starts