Klynt Baker, the recently appointed president of Sonnax and Rostra, says that his responsibilities aren’t two aftermarket companies owned by Marmon Holdings. Baker says that Sonnax and Rostra have integrated their operations to the point that there are indeed two brands encompassed in a single business.

The Marmon Automotive Aftermarket Group is a subsidiary of Berkshire Hathaway. In the years since the 2017 and 2018 acquisitions, Sonnax and Rostra have woven themselves into a single company that serves the market with two well-known brands.

Transmission Digest spoke with a team of development, brand management and company executives both in in Laurinburg, NC and a couple of weeks later at the company’s headquarters located in Bellows Falls, VT. Many of the discussion participants were present in both locations, an indicator of the interwoven development team model they have created.

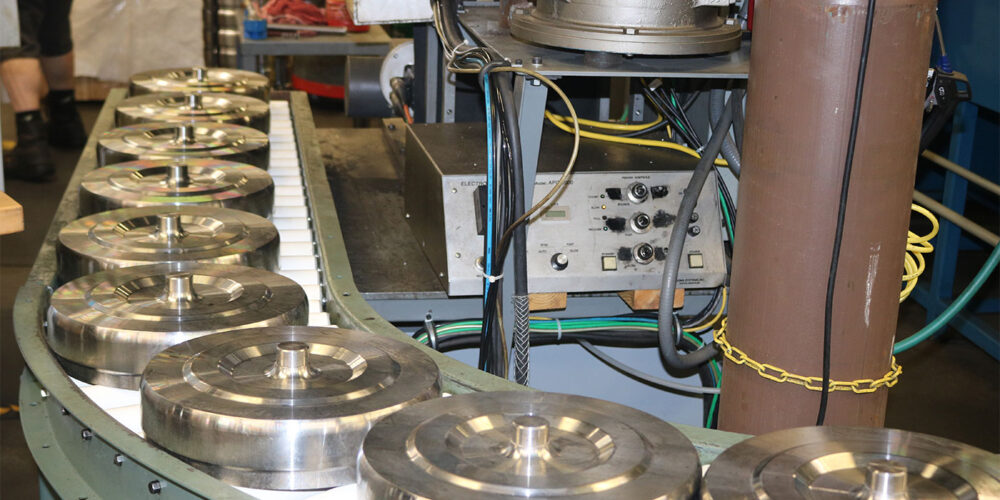

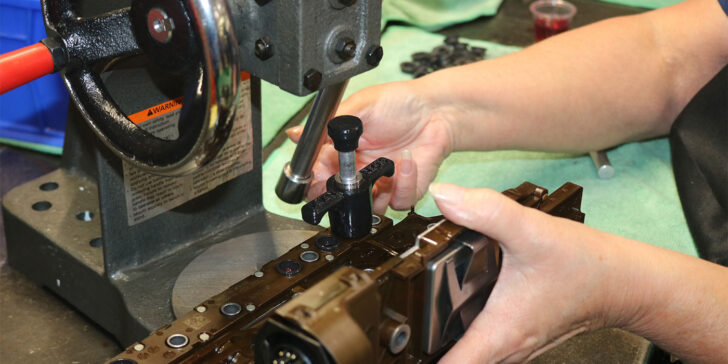

Products including remanufactured valve bodies, solenoids, harnesses, TEHCMs, sensors and modulators are handled at the North Carolina facility. Supplying transmission specialty parts, torque converter parts, driveshaft components and performance racing solutions fall into the operations at a trio of Bellows Falls facilities.

While the product assortment from these related brands is diverse, the R&D efforts have a commonality in addressing builder concerns based on common wear factors or parts failures. For instance, the team says a common solenoid failure might result in the engineering and manufacture of a Rostra aftermarket replacement. That replacement part may go to the marketplace as a single solenoid, and as a component to be used in the Sonnax valve body remanufacturing operation.

Beth Houder, who oversees marketing for both brands, explains: “We’re very lucky with the synergies that combine all of our experience and all of that brain power under Maura Stafford’s [the VP of transmission products] leadership. And, I can’t say enough about the job that plant managers Ula Fernandez and Dawn Wright have done to help both groups which didn’t know each other before.

”We moved our valve body facility from New Jersey to North Carolina in the middle of a pandemic! Fostering that team spirit and culture has been icing on a cake in support of the larger mission,” Houder said.

“There were tons of challenges along the way,” adds Rostra’s engineering manager Scott Kirkendall. “There’s a core group of Rostra folks that have been together for a long time and through transitions a number of times. We’ve had seven ownerships since the days the company was known as Century Brass. When this merger happened we all had a very open approach to it.

“Maura got the Vermont engineering resources involved in how we do a particular task, whether it’s developing a product, releasing a drawing, or whatever,” he continued. “We did the same for quality and really for all of our business practices. We compared, and settled on the best practices that work. It’s okay if something is a little bit different between locations as long as we understand how it works. We did adopt the ERP system that was being used in Vermont.

“Again, crediting Maura, when we were going through these challenges of integrating our engineering she would not say, ‘okay, we’re gonna do this, we’re gonna do that.’ At all times she was looking at the entire picture.”

“We’ve always done R&D for Sonnax in Vermont,” Stafford added. “And then, when we combined with Rostra, it was really the best of both worlds. For example, North Carolina no longer had a vehicle lift or the capabilities to do the some of the data acquisition and the testing. But we have those capabilities and those people in Vermont, so we can support and add to their efforts.

“At Sonnax, we can set the parameters and define what is good,” she went on. “We want our standard to be at least as good as OE. Then as we continue to prototype—whether it’s for valve bodies, any kind of transmission, part, converter—we can use the testing in Vermont against the benchmark of OE and say, ‘okay, here’s our design. Here’s our prototype. Let’s put it in the vehicle, and verify if it works the same or if we need to continue to refine that solution.’”

“One of the significant advantages of the Sonnax/Rostra integration is how much it helps our speed to market,” Mark Kaplan, vice president of sales, added. “We have synthesized quality standards and practices as well. We’re learning a lot from each other.”

“We’re continuing to work as one in a lot of areas,” Kirkendall noted. “Our North Carolina based purchasing manager, John Grimes, worked with the RVB staff in getting them introduced to the Rostra brand supply base because we may have had some components they could use. There’s a component or two in the TEHCM that we had previously tooled for another product and realized we could start to supply them for the TEHCMs.”

Kirkendall shared that the company’s North Carolina facility supplies not only later components like the TEHCM and the transmission specialty line of transmission electronics, but also some near-vintage parts that no longer would be considered popular. He points out that the company is one of the last, if not the last, supplier of vacuum modulators for older transmissions.

“The most popular vacuum modulator is going to be a TH350,” he said. “We’re also producing the early 4T60s that used a modulator to control line rise, and we still make Powerglide modulators. Most of these are for people that have race cars or street cars that they are putting them on, but they’re just stock. We probably produce about 80,000 modulators a year, including the C3, C4, C5, C6, FMX and A4LD applications. In fact, we were the OEM supplier for Ford previously.”

During the time when the Rostra and Sonnax teams were working to integrate almost every aspect of their businesses, the COVID 19 crisis occurred, adding quite a bit of challenge to their efforts.

“During the pandemic we had no layoffs,” Kaplan recalled. “We deployed people from all areas of the organization to the warehouse to help kit and package parts to keep products flowing to customers. There was such an increase in demand during that time that we were starting to fall deep into a backlog. To catch up, we utilized everybody that we could.”

Houder added, “At the time to help us get out of that backlog, we had 25% of the office workforce on any given day working in either the warehouse or light assembly. And then on top of that, on any given Saturday for either a four-, six- or even eight-hour shift, you could find another 25 or 30 people working. It was a tremendous effort and learning opportunity.”

“It was the increased demand we were trying to meet. We found so many continuous improvement projects and opportunities,” Baker noted. “Sixty-two of those projects pertained to us working with our suppliers to receive product in a more suitable fashion for packaging. Any and all opportunities were explored. They were identified by the product line managers who were participating with the purchasing and sourcing team. Everybody got to touch an area that they normally didn’t touch, raised their hand and said, ‘why do we do it this way?’

“It also made a good connection between our teams so that we had great two-way communication between our warehouse and packaging team and all other teams that were creating these projects, but now began to understand what happened downstream.”

“That spirit of continuous improvement is part of what makes Sonnax, Sonnax,” Houder added. “And it runs deep: More than half of our employees have been with the company for at least 20 years.”

“Continuous improvement is a core value at Marmon, too,” Baker noted. “With their support, we have accelerated investments to expand our manufacturing capabilities and capacity so we can better serve our customers. Sonnax and Rostra Powertrain Controls have faithfully served the aftermarket for decades, and we have an exceedingly bright future ahead.”