“A few years ago, Tom Eibel and I visited with many of Rostra’s customers,” Rostra Powertrain Controls President Jeff McCurley said. “We heard repeatedly that they loved Rostra products but wished Rostra would develop and release more parts.”

McCurley and much of Rostra’s executive staff – including Eibel, Rostra’s Vice President of Sales and Marketing – sat down with Transmission Digest last month at the company’s headquarters in Laurinburg, N.C.

When asked what was new since our last visit here the team highlighted two new research and development facilities and a state-of-the-art website. Building on more than three decades of experience in the transmission-related electronics industry, Rostra, they say, is primed and ready to hit the gas on new product development this year.

“Rostra has more than 30 years of transmission-related electronic applications knowledge -knowledge gained through the company’s relationships with OEMs, OE service and independent aftermarket customers in the powertrain industry,” Eibel said. “Listening closely to our customers, we knew Rostra needed to accelerate our product development efforts.”

To increase its product development efforts, Rostra recently opened two additional research and development facilities, one in the Raleigh, N.C., area and the other in Grand Rapids, Mich. “Staffing these new facilities with engineering talent from the OE industry, along with program management and data analysis capabilities was key to supporting the development goals for next-generation transmission products,” McCurley said.

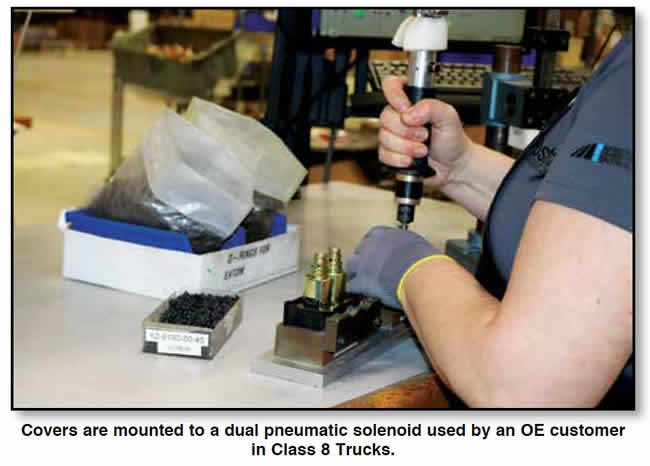

Regarding product development, Eibel said the current engineering focus is on solenoids, sensors and related products for 6-, 8- and 10-speed platforms for Ford 6F and 6R, GM 6T, Toyota U series, ZF 6HP and 8HP applications with specific focus on Variable Bleed Solenoids. Eibel said hiring engineers who have OE experience has significantly decreased the amount of time required for Rostra’s development process. “We’re applying what the engineers already know from design and manufacturing on OE 6-speed transmission products and applying it to Rostra’s aftermarket product lines,” he said, adding that he expects to see roughly 17 new VBS applications released throughout the year.

“It’s taken the aftermarket a long time to catch up to the demand for Jatco CVT replacement parts,” Eibel said. “We are listening to our customers and we are working as fast as possible to bring new products to market. We are in a marketplace that has been forced to install used hard parts and electronics during the transmission rebuild. Rostra is the first transmission electronics company rapidly developing a full line of products to cover early JF009, 010 and 011 and late-model JF015, 016 and 017 applications. Components to be released later this year include solenoids, switches, sensors, stepper motors and wire harnesses.”

Eibel continued, “Sensors and harnesses have grown to become a substantial portion of our business in addition to our well-known line of solenoids. The industry will be seeing a lot more wire harnesses ¬– early- and late-model domestic, Asian, European – being introduced by Rostra this year.”

The product development team is also rounding out a complete line of electronics for the Aisin Warner and Toyota units that include U660, A750, U150/151, and U250/251.

McCurley’s background includes extensive engineering and leadership roles with both OE and aftermarket manufacturing companies; experience that matches well with Rostra’s position as both an OE and aftermarket component supplier.

“Rostra’s OE roots align well with the quality expectations demanded in the independent powertrain aftermarket,” McCurley said. “Rostra’s manufacturing facility has held certifications for both TS 16949 and ISO for many years. In the past two years we’ve been recertified, updating to ISO 9001:2015 and achieving IATF 16949:2016, the highest level of certification earned for OEM suppliers.”

Eibel said that Rostra continuously promotes its OE experience, quality and reliability across all product lines. “Those transmission products include solenoids, harnesses, switches, sensors, vacuum actuators and still some vacuum modulators,” he said. “Our OE background proclaims and emphasizes the quality and functionality of what we manufacture as opposed to ‘white box’ product that comes from overseas. Our aftermarket products come from the same production lines, the same supply base, the same processes and the same people that supply the OE components we sell. I guess you’d have to say that Rostra truly is that OE company that people don’t automatically think about as being OE.

“Rostra Powertrain is committed to serving the OE and aftermarket needs of its customers and end-users,” Eibel said.

A perfect example of this is the company’s brand-new website, which was created by its marketing team with the goal of providing the necessary tools for locating the correct parts in any application. This can be seen through the new website, which provides part lookup capabilities by vehicle make, model, year and transmission type. A mobile version of the site that allows end-users to navigate the page – whether it be under the hood or on the go – was also recently released. Another sought after feature to look for soon will be the VIN lookup that will ensure correct part identification.

The new website, according to the company, brings many other features such as new high-resolution photos that display multiple angles of various parts for better visuals of connectors, terminals and those typically hard-to-see areas. Another useful feature on the site is the ability to search for parts using the OE or various industry part numbers. Rostra Marketing Manager Justin Tatum said, “We feel it’s important that our customers’ voices are heard and that we utilize their feedback to provide the necessary tools needed to simplify what can be a fairly complicated market due to the ever-changing applications and electronics.”

Regarding how Rostra products are sold into the market, Eibel said, “Our main aftermarket customer base consists of the two-step distributors. We also supply the major transmission remanufacturers. Their needs require our direct involvement, and to a great extent, they help us develop the solutions that are available to the retail shops.

“We strive to be a good corporate citizen. Rostra attends industry events both in support of our customers and to listen to what the retail shops are needing to do their work. If you look at the manuals from those seminars, the content is 60% or 70% electronics. Everything from tuning and calibration to failure analysis starts with electronics. We feel the responsibility to be helping our industry by providing a better understand of the electronics that are controlling those units.”

Looking forward, the Rostra team finds abundant opportunities to develop additional components that are needed by the industry.

“We continue finding opportunities to develop both OE and aftermarket products,” Eibel said.

Marmon Brings Powertrain Synergies

In 2017, Rostra was acquired by Marmon Holdings Group, a division of Berkshire Hathaway. The group derives its name from the Marmon Motor Car Company (1902-1933). On May 30, 1911, Marmon’s Ray Harroun drove the Marmon Wasp to victory in the first Indianapolis 500 race. The Marmon team combined innovation, differentiation and intense focus on what mattered most to winning. More than a century since Ray Harroun drove the Wasp to victory, Marmon is still growing thanks to the strength of focus and the quality of their people.

Marmon recently also acquired Sonnax to add to their industry wide coverage. Their automotive groups have dozens of locations around the world, concentrated particularly in the U.S., Mexico, Europe and China.