Torque Converter Tech Tips

- Subject: Pilot wear, cracked flex plates

- Unit: GM 4L80-E converter

- Vehicle Application: GM trucks/SUVs, 1999 up

- Essential Reading: Converter Rebuilder, Transmission Rebuilder, Diagnostician

- Author: Ed Lee

Worn-pilot and/or cracked-flex-plate issues return on the GM 4L80-E converters

Most torque-converter rebuilders routinely deal with the undersize pilots on GM 298mm converters. It is common either to build up the pilot by welding and then re-machine, or to sleeve the pilot area. The issue is so widespread that the repair is a requirement on the OE remanufactured-converter process.

The reason 298mm converters have pilot-wear issues is that the surface area on the pilot, which is used to center and support the converter, is not large enough to support the weight. You might expect the mating part of a high-wear item also to have wear issues, but in this instance, the mating part that supports the 298mm pilot is the cavity in the end of the crankshaft. Fortunately, the crankshaft has better wear characteristics than the converter pilot and does not require repair as often.

Today, the converter for 4L80-E transmissions is having wear issues similar to what is common in the 298mm converter, along with some additional complications. Once more, the primary reason for the wear issues is a support-area-to-weight problem. 4L80-E converters are heavier than the 298mm converters and do not have much more piloting surface area.

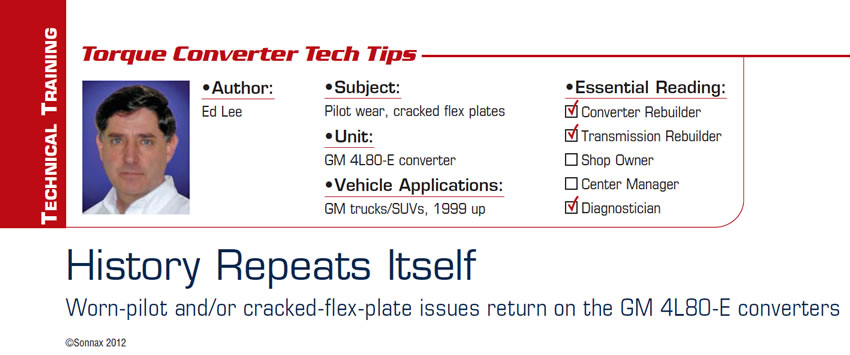

To make things worse, on some models the mating surface at the engine also is having wear issues. The models affected are GM vehicles equipped with 4L80-E transmissions and V-8 gasoline engines, 1999 to present. On these models the converter pilot does not center in the crankshaft itself but instead is supported by a spacer sandwiched between the crankshaft and flex plate. This spacer (GM part number 12563532) costs about $37 and more often than not will need replacing during an R&R. The wear visible on the spacer in Figure 1 caused it to be 0.017 inch oversize.

Wear in the inside diameter of the spacer is the root cause of most of the cracked flex plates frequently found in these units. The I.D. of the bore should be measured during every R&R. It would be a good idea for the converter rebuilders to include a reminder with each 4L80-E converter. This could prevent an unnecessary comeback for both the transmission shop and the converter builder.

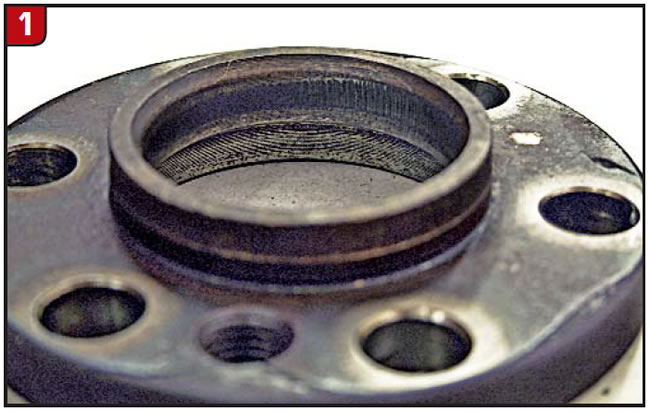

The pilot outside diameter and spacer-bore I.D. should be measured in at least two positions, about 90° apart (Figure 2).

Clearance beyond 0.005 inch maximum should be corrected. A go/no-go gauge is not a suitable method of measuring the pilot or spacer bore, because it will pass too many defective parts.

Ed Lee is a Sonnax technical specialist who writes on issues of interest to torque-converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.

©Sonnax2012