The Stop/Start feature many vehicles are equipped with today is in my opinion one of the most annoying features a vehicle could ever have. Of course, my opinion doesn’t reflect the opinion of others, but what is undeniably annoying is when the stop/start feature is not working correctly, especially when it is self-inflicted.

Take, for example, a GM 8L90 transmission. There is a valve body designed to be used in this transmission for vehicles that are equipped with this type of technology. The changes to the valve body are quite subtle and could be missed if one is not aware of them. So, if this style of valve body is used in a non-stop/start application, the transmission will appear to be working properly in a vehicle when it is up on the hoist; but once it is on the ground, it will barely move.

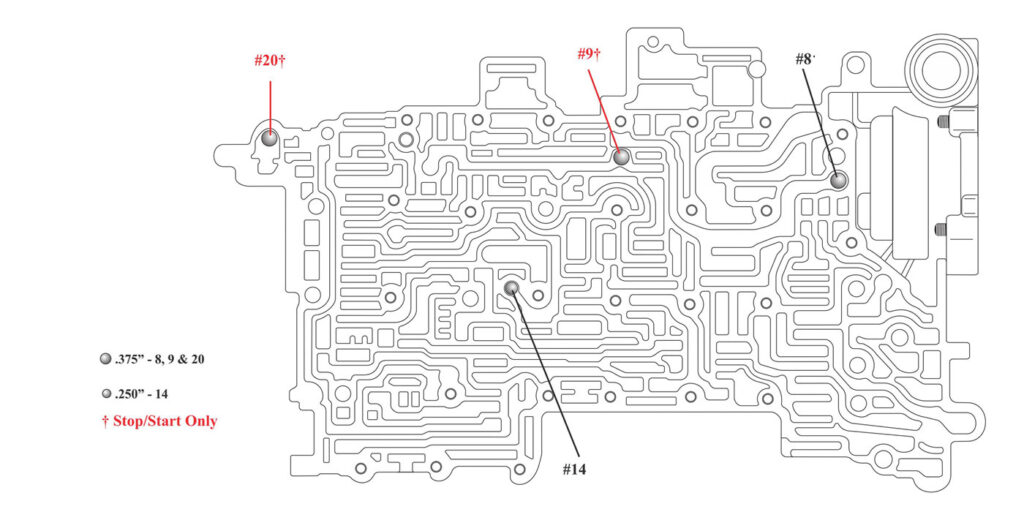

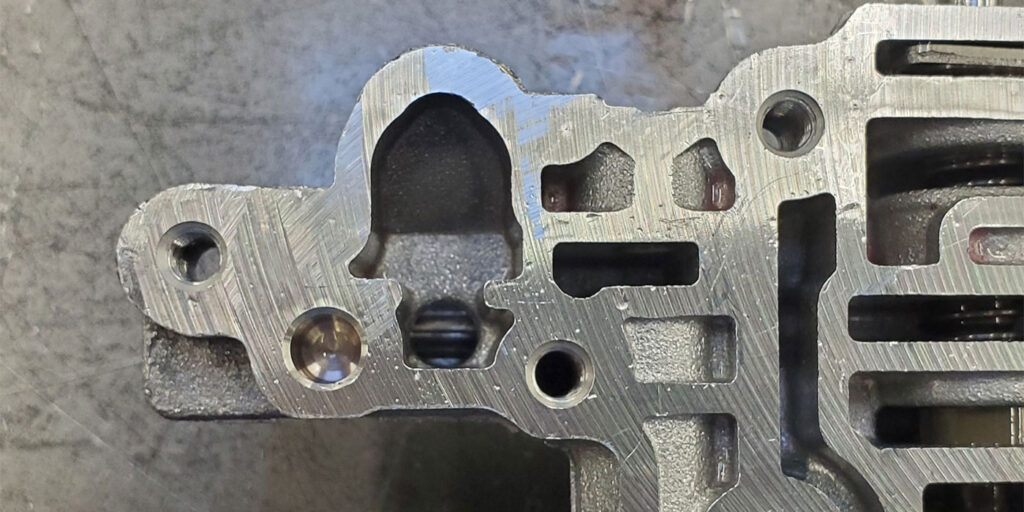

The stop/start valve body entails more than having two extra check balls (#3 and #20) as pointed out in Figure 1 to identify its difference.

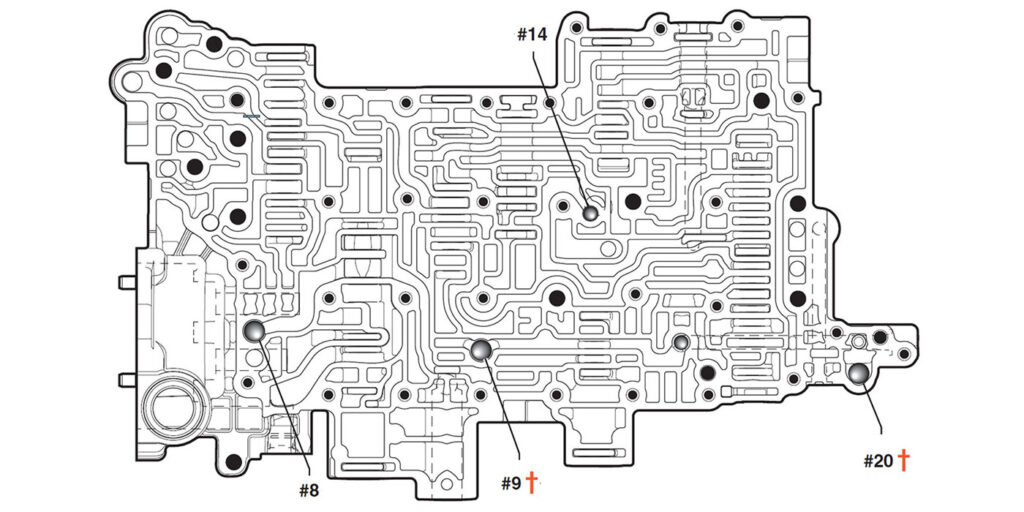

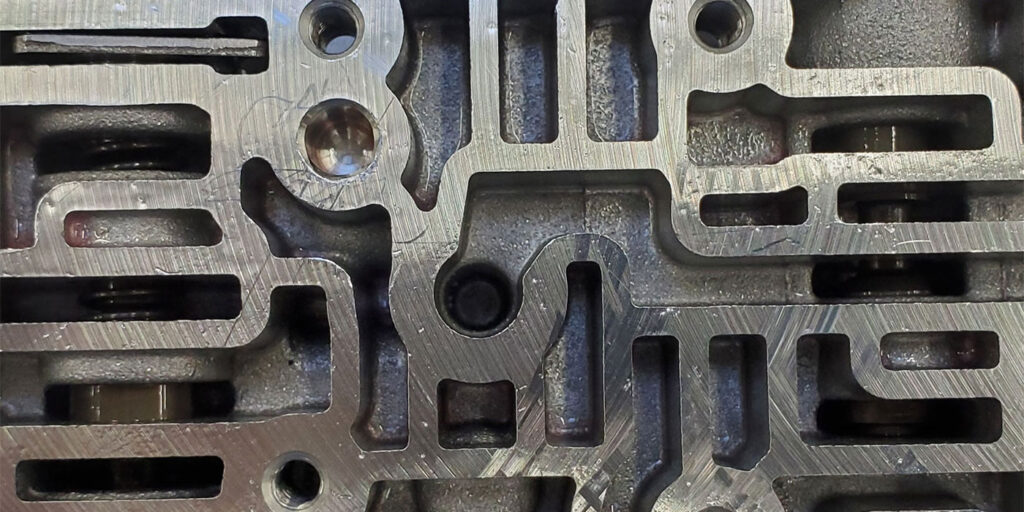

When you look at the check ball locations in GM’s Technician Guide (Figure 2), it points out the same two check balls as seen in Figure 1. But, notice that it has two passages in dotted lines associated with these two check balls.

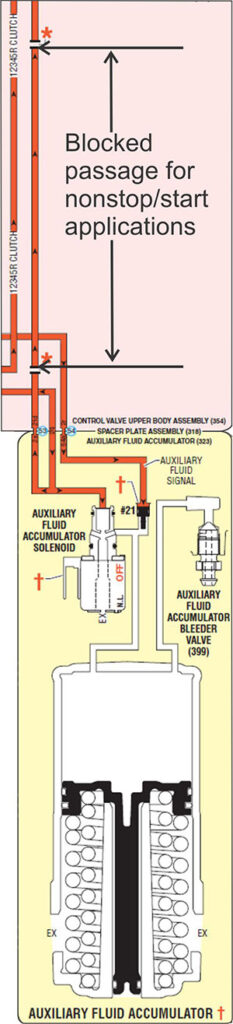

When you look in the hydraulics related to this circuit, it shows that these passages are blocked in non-stop/start applications (Figure 3). This means these two circuits are open and functional with a transmission that has this stop/start feature.

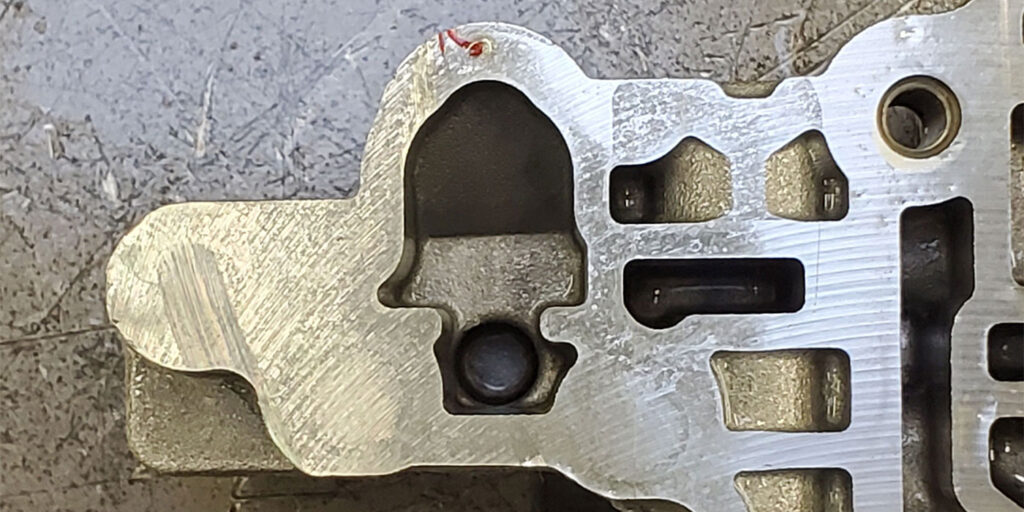

To see these subtle differences, Figure 4 shows the corner of a non-stop/start valve body, where the #20 check ball would be located on a vehicle with the stop/start feature.

Figure 5 is a valve body with this feature. Just a cursory look in this area would cause one to easily overlook that the passage in Figure 4 is blocked while in Figure 5 it is open.

The same can be seen in the circuit going to the #9 check ball by comparing Figure 6 with Figure 7. Figure 6 shows the circuit being blocked, whereas Figure 7 shows it open. These circuits are like underground troughs formed into the casting of valve body.

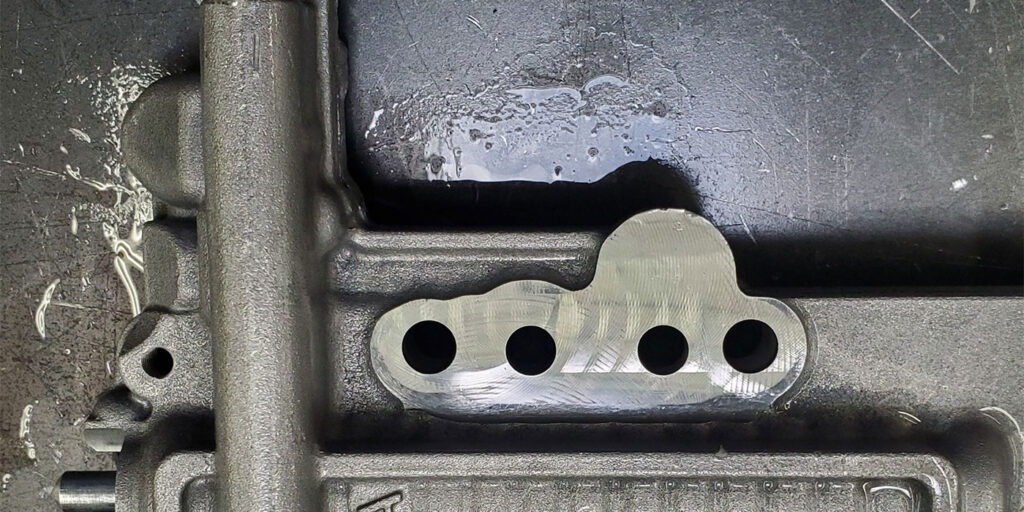

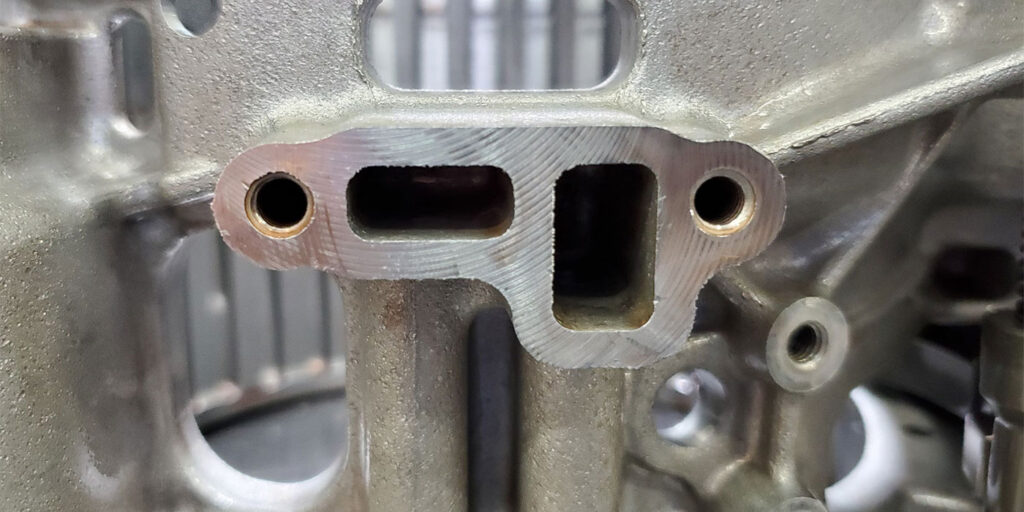

One quick way to identify a stop/start valve body is by looking at the case side of the valve body. There will be an additional hole to supply pressure to the 12345R clutch from the auxiliary fluid accumulator assembly. Figure 8 shows a non-stop/start valve body, while Figure 9 shows the additional hole the stop/start valve body provides.

The way the case is designed with an elongated north/south rectangular feed passage means that it will accommodate both one-hole and two-hole valve bodies (Figure 10). This additional passage is routed towards the #20 check ball.

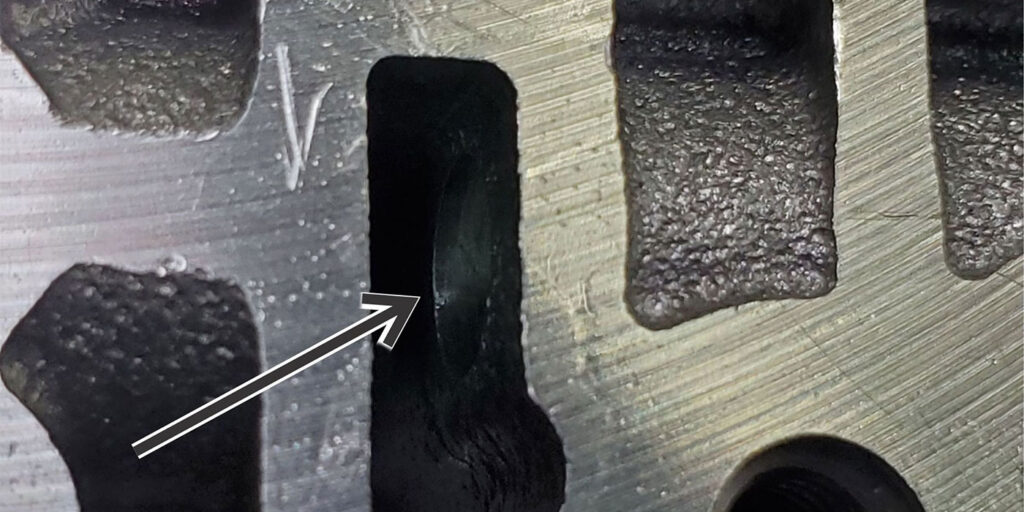

Figure 11 is an attempt to show how these passages are like underground troughs formed into the casting of valve body. A flashlight was placed onto the additional feed hole seen in Figure 9. Looking at Figure 11, an arrow is pointing at the opposite end of the passage where a little of the light is shinning through.

Without knowing these little details, a stop/start valve body can be easily installed in a non-stop/start application. And this will be the difference between having a go or no-go transmission.

Keep in mind too that it’s just as easy to do the opposite. Installing a non-stop/start in a stop/start application will cause a delayed and abrupt engagement into gear after engine startup.

Each mistake makes for an annoying self-inflicted injury. Hopefully, this article will help prevent this from occurring for others.