Today we are examining what we’ll call a “Twilight Zone” transmission complaint: an issue that appears out of nowhere while performing a small, insignificant repair and initially makes little sense. The 8L45 and 8L90 3-4 Neutral condition, which has been baffling many shops/techs, is one such complaint.

Problem: 3-4 Shift is Neutral after installing a temp sensor and updated wiring harness.

Initially, this complaint occurs because the vehicle arrives at the shop with a P0711 TFT temp sensor code. I have also run into this with dealer-auction vehicles that end up in automotive and transmission shops for work. The repair usually requires replacement of the temp sensor along with an updated harness, which requires valve body removal and reinstall. This should not be a complicated repair, but Murphy’s Law starts playing havoc in the background.

Cause: Wiring harness was incorrectly installed.

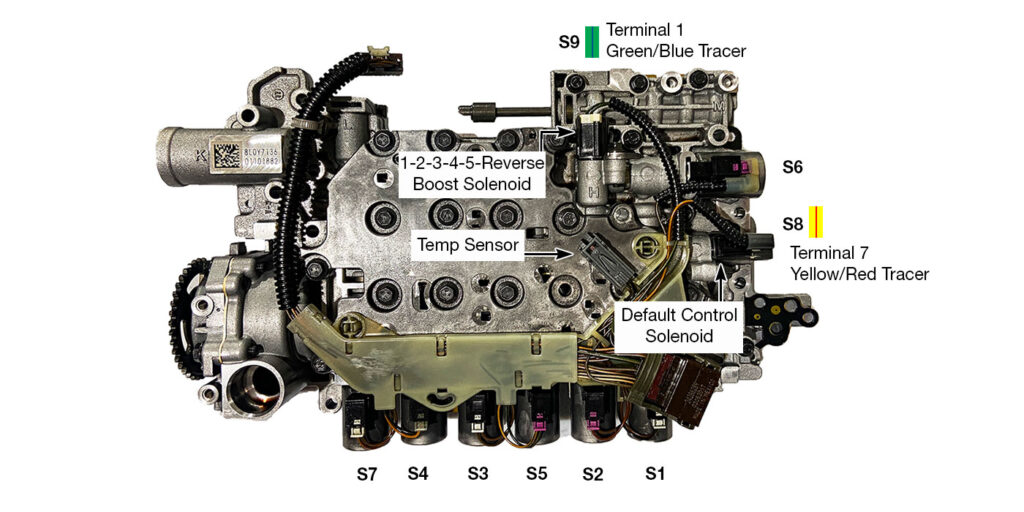

To the point, the 3-4 Neutral occurs in 8L45 and 8L90 units because the S8 default control solenoid and S9 1-2-3-4-5-Reverse boost solenoid electrical connectors were swapped and hooked up incorrectly when the valve body and harness were reinstalled. The S8 default control solenoid and S9 1-2-3-4-5-Reverse boost solenoid are identical and share the same type of electrical connector, so it’s easy to assemble this incorrectly.

For an understanding of what occurs technically: when fourth gear is commanded, the S8 default control solenoid is on; however, it now controls the S9 solenoid. S9, from now on, allows AFL oil pressure to travel through the solenoid to 1-2-3-4-5-Reverse clutch boost valve and stroke it against the spring-exhausting 1-2-3-4-5-Reverse clutch. This is the Neutral condition.

Diagnosis and fix: First-time diagnosis can be a chore

Without knowing the above, diagnosis gets rather tricky since many tech resources have these two solenoids incorrectly labeled as well as incorrect wiring diagrams. In other words, popular tech resources would lead you to believe an incorrect assembly is correct. Talk about confusion!

Power flow and recorded scanner movies make little sense either. Many shops/techs, frustrated at this point in the repair, have replaced the valve bodies thinking that’s a possible solution, all the while installing the wiring harness and valve body incorrectly a second or even a third time.

After a point and going further in depth by checking the basics, such as wiring with a diagram that’s known to be good, things suddenly start falling into place. You will find that the first wire you normally check on terminal 1 is hooked up incorrectly, which means another wire is also hooked up incorrectly. Suddenly you discover that two solenoids are incorrectly plugged in. Progress!

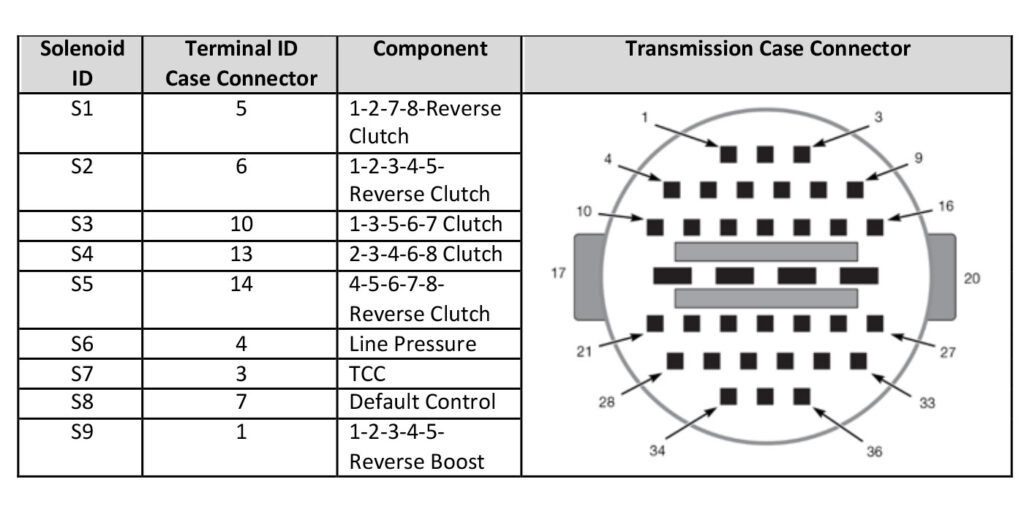

To verify the harness issue, check Figure 2 below. The S9 1-2-3-4-5-Reverse boost solenoid has 3.75-in. of conduit and a green wire with blue tracer to terminal 1 of connector. The S8 default control solenoid has 1.75-in. of conduit and a yellow wire with a red tracer to terminal 7 of the connector. The information in this article has been verified on multiple vehicles, and Figures 1 and 2 show correct assembly.

Thank you to Bob Nielson, owner of Bob’s Transmissions in Kansas. Bob first experienced this complaint, and his technical contributions were instrumental for this article.

Read more columns from the TASC Force Tips series here.

Jim Mobley is a Sonnax technical communications specialist. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of industry technical specialists, transmission rebuilders and Sonnax Transmission Co. technicians.