Shift Pointers

- Author: Mike Souza

Beware of mismatched parts when working on some transaxles

As almost all of us are aware, a technician can easily create a scary nightmare when trying to mix and match parts while making repairs to some of Ford’s automatic transmissions. A classic example of this is interchangeability of the lockup solenoid (LUS) for the 1991 AXOD-E (AX4S) transaxle.

In 1991 the Taurus/Sable models used a square-shaped on/off-type LUS that measured 21-36 ohms resistance. The Continental was using a round-shaped pulsed duty-cycle type solenoid (MLUS) with a resistance of 0.98-1.6 ohms with a more-sophisticated electronic control strategy that provided for a smoother lockup apply feel. The Taurus/Sable models did not use this type of system until the 1992 model year.

The nightmare would appear when you used the low-resistance MLUS in a 1991 Taurus or Sable with a PCM circuit driver that was not designed to handle the amount of current and resulting heat generated when this low-resistance solenoid was simply switched to ground rather than being pulsed or duty cycled. As a result, Fred would let some smoke escape and you ended up with a car that would snub the engine as soon as you put the shifter in Drive or would have uncontrollable lockup on top of second gear.

Besides the obvious electrical boo-boo, there are other drivability concerns that can be created by mismatching these solenoids. The correct pump plate and valve-body spacer plate to go with the solenoid also must be used, as there are major differences in the orifice sizes controlling the flow of oil through the solenoid. This is not obvious at first glance unless you know what to look for, but that’s another story.

Well, it looks as though Ford has thrown us another curve ball recently. That low-resistance MLUS was used consistently in the 1992-96 AX4S and in ’95-96 AX4N transaxles. However, in 1997, again with only Continentals, Ford started using a different MLUS. You can identify this new-design solenoid quickly by the blue connector and its resistance value of 13-24 ohms. As stated previously, the earlier MLUS measured 0.98-1.6 ohms. It had a white connector.

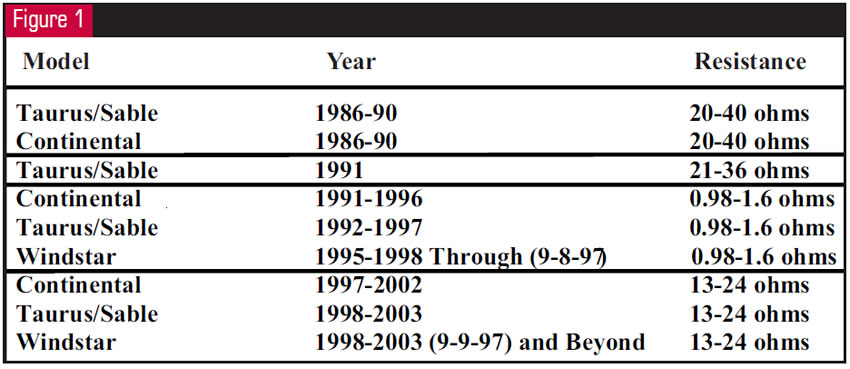

Taurus, Sable and Windstar started using the later solenoid for the 1998 model year, not in 1997 like the Continental. The information in the table in Figure 1, taken from Ford TSB # 03-12-3, will clarify in which model and year these changes actually occurred. Take notice that 1998 Windstar models could have either solenoid. If referring to the Ford factory service manual or some aftermarket service publications for the 1998 Windstar, you will see specifications for only the low-resistance solenoid. This is why it would be a good idea to refer to the VIN when ordering the TCC solenoid for this model year.

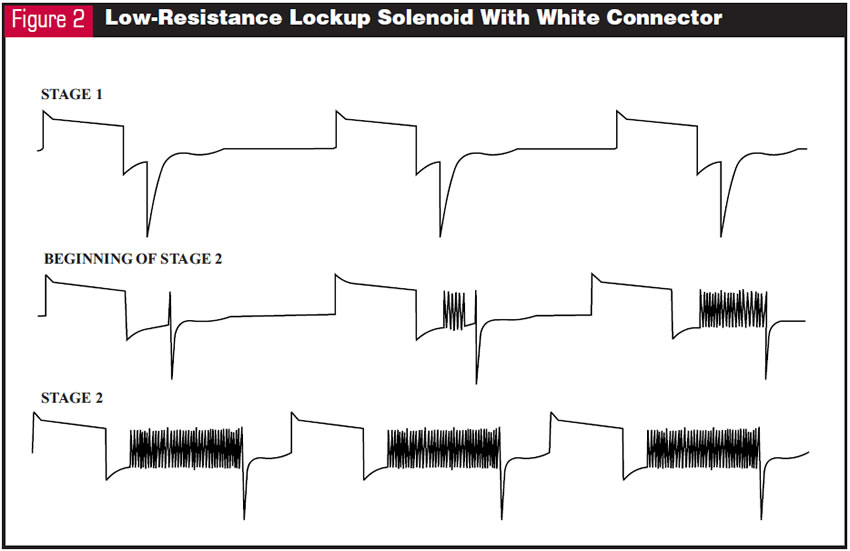

Along with the change in the solenoid winding, there is also a change in control-system strategy or the way the solenoid is pulsed. The early-design low-resistance solenoid is duty cycled with a two-stage PWM signal. The first stage of pulses begins at a frequency of 66 Hertz (Hz). Then the second stage of pulses will increase to control the output pressure of the solenoid as needed to bring the converter slip speed to zero (see Figure 2).

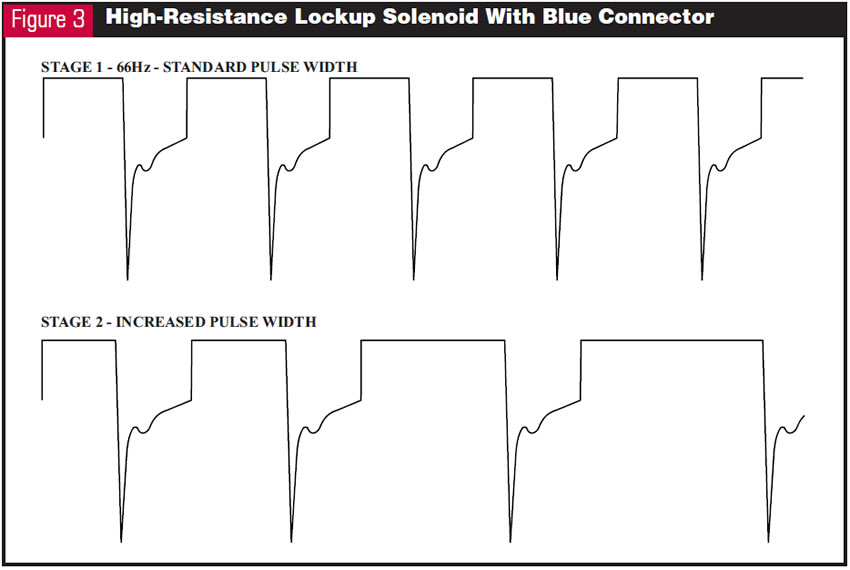

The higher-resistance MLUS with the blue connector employs a different control-system strategy from what was used with the earlier-design MLUS. This solenoid works from a fixed frequency of 50 Hz with a standard PWM square wave, increasing the pulse width to control the converter-clutch slip (see Figure 3). This current-design solenoid and operating strategy will allow the solenoid to run cooler and last longer.

Ford said the new-design solenoid would not retrofit earlier models, as stated in Technical Service Bulletin 03-12-3. In some instances this solenoid may work on earlier-model Lincoln, Taurus and Sable vehicles originally equipped with the white-connector solenoid without any noticeable effects. Other times you may have a complaint of a surging condition or fluctuating engine speed during lockup apply, with a bump at the end of the engagement.

This is because the later solenoid, by design, does not mechanically react as quickly as the earlier solenoid to the first stage of pulses used with the early PWM control strategy (see Figure 2). When the second stage of pulses nears the end of the signal, the solenoid responds more quickly, resulting in the end bump apply causing this complaint. There may be a fault code such as PO741, P1744 or P1728 (TCC-solenoid performance or engagement fault) stored in PCM memory. However, even though the later solenoid has a higher resistance, it will not cause a circuit or electrical fault code to be stored when used in place of the early low-resistance solenoid and operating with the earlier control-system strategy.

I have found that if you placed an early-design low-resistance solenoid into a later vehicle originally equipped with the blue-connector high-resistance solenoid, you would see an electrical-circuit fault code such as PO743 stored almost immediately when the PCM commanded lockup on. This later control system does not appreciate the extra current moving over that wire when you use the early MLUS – OOPS!

Now let’s take a look at the 1998 Windstar. As already stated, this vehicle may have the white-connector low-resistance MLUS or the blue-connector high-resistance MLUS. It appears that computer strategy for this vehicle is slightly different from that of the Lincoln, Taurus or Sable. This system seems to be looking for a faster drop in engine speed during lockup apply. If you were to watch the TCC duty-cycle percentage as it ramped up from 0 toward 100, you would see that if it reached 100% but the slip parameter did not go to 0, or maybe it did go to 0 but did not hit 0 fast enough, the solenoid would be commanded off and then start over again up to three to five times.

At this point, if the slip parameter indicated that the attempt to lock the converter clutch was unsuccessful, the solenoid would remain off, the PCM would store a TCC-solenoid performance fault code and jack up the line pressure. The malfunction indicator light (MIL) would be on and the transmission would be shifting hard. Turn the key off and the whole process would start over until the fault repeated itself. Most of the calls taken here at ATSG have involved the Windstar having this complaint when the white-connector solenoid was replaced with the blue.

As a precaution, it would be safer to use the solenoid that was designed for the year, make and model that you are working on, along with the correct system that controls it. If the dealer repeatedly delivers an incorrect solenoid, saying it will retrofit earlier models than it was designed for, just order the solenoid by the base part number, which is the middle numbers between the two dashes of the complete part number. For example, in F3DZ-7G136-AA, 7G136 is the base part number for a PWM lockup solenoid. When using only the base number along with the vehicle’s VIN when ordering the solenoid, you should receive the correct solenoid designed for that vehicle and computer system.

Are we having fun yet? Alrighty then, let’s have some more! We finally have the correct solenoid for our own particular Windstar. The vehicle is ready to be delivered. One final road test and we can ship it. During the initial road test everything seems fine until we start up a slight incline. As you crowd the throttle to maintain your speed on the hill, you feel a chatter. As Homer Simpson would say, DOH! Of course, back in your own shop you may find more-explicit expletives to recite.

This particular complaint may be a result of not using the correct torque converter for this application. The 1995-2003 Windstar with a 3.8-liter engine and AX4S transaxle requires a dual-modulated (two-sided) converter clutch. The 1996 and 1997 Taurus/Sable also use a dual clutch when equipped with the 3.0-liter four-valve engine and AX4N transaxle. The 1995-2001 Lincoln Continental with a 4.6-liter engine and AX4N transaxle uses a low-stall dual-clutch converter. Using a converter with a single friction clutch in place of an original dual-clutch converter may cause this problem under certain load conditions. With equal apply pressure in either converter, it stands to reason that lockup apply time will be less and load-carrying or holding capacity will be greater with the dual-clutch converter.

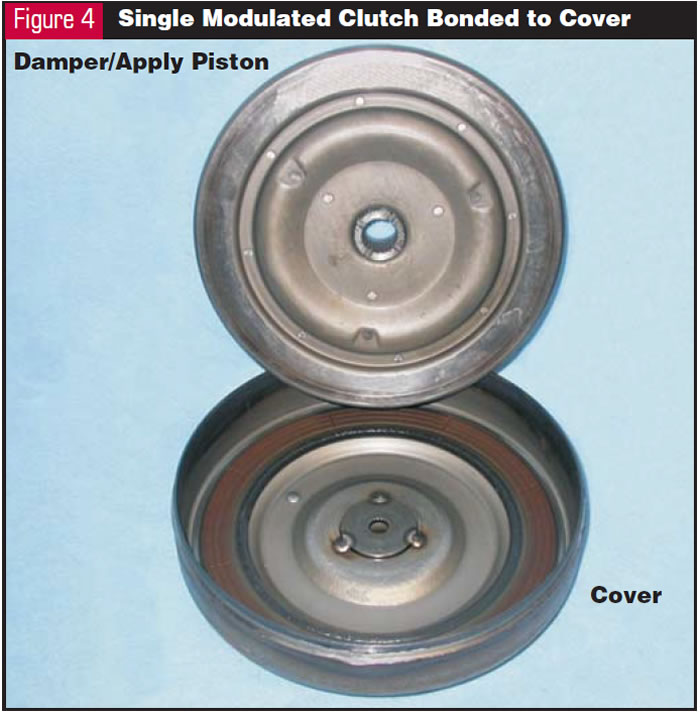

To view some of the differences in these torque converters, see figures 4 through 13. Figure 4 shows the single-modulated converter clutch. Note that the friction surface is bonded to the converter cover with the damper/apply-piston assembly above it in the photo.

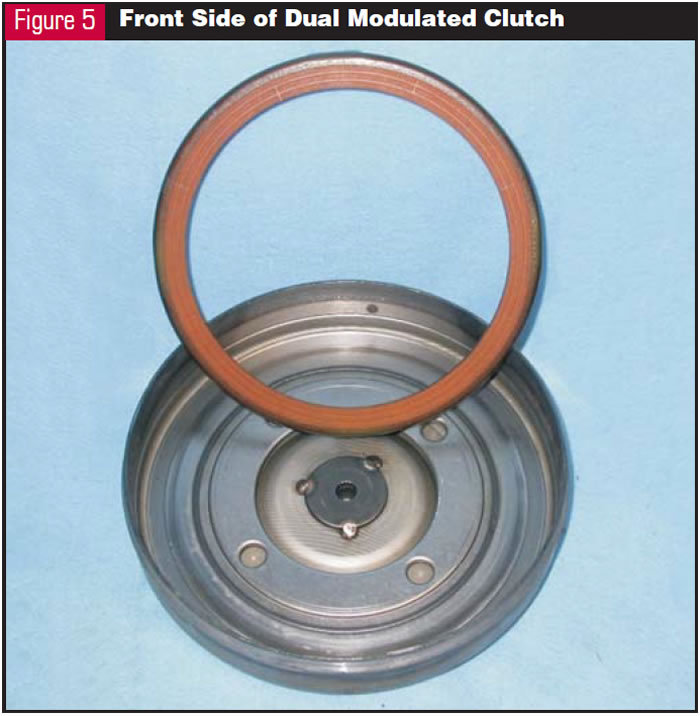

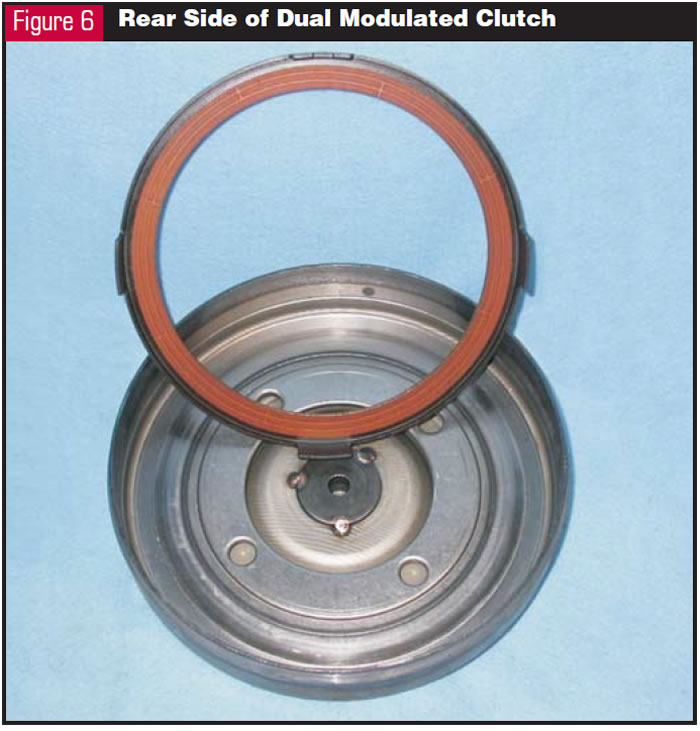

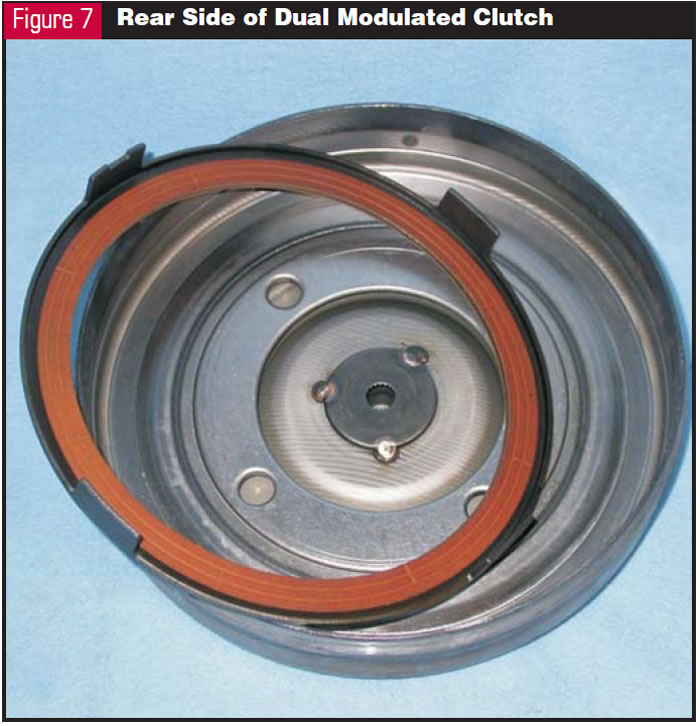

Figures 5 through 7 show the dual-clutch type. Here you can see that friction surfaces are bonded to both the front (Figure 5) and rear sides (figures 6 and 7) of the dual-clutch assembly.

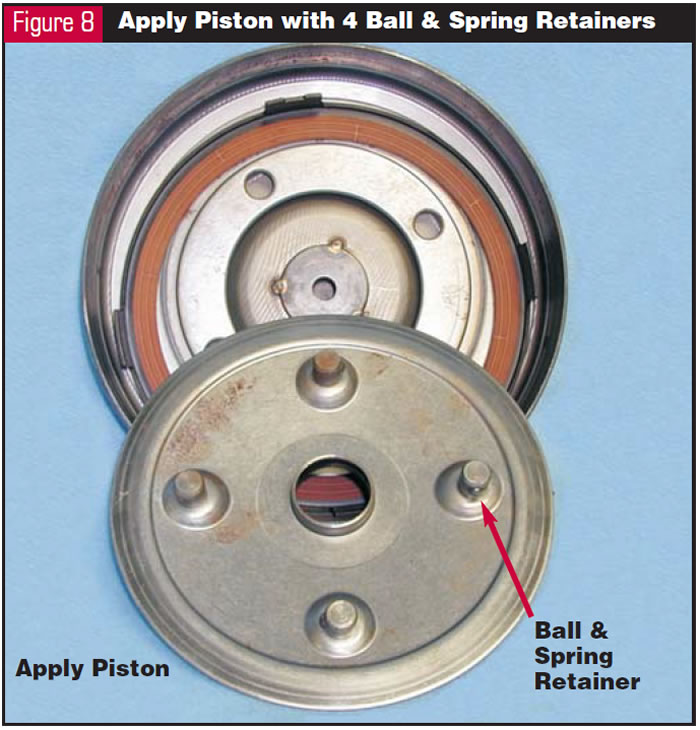

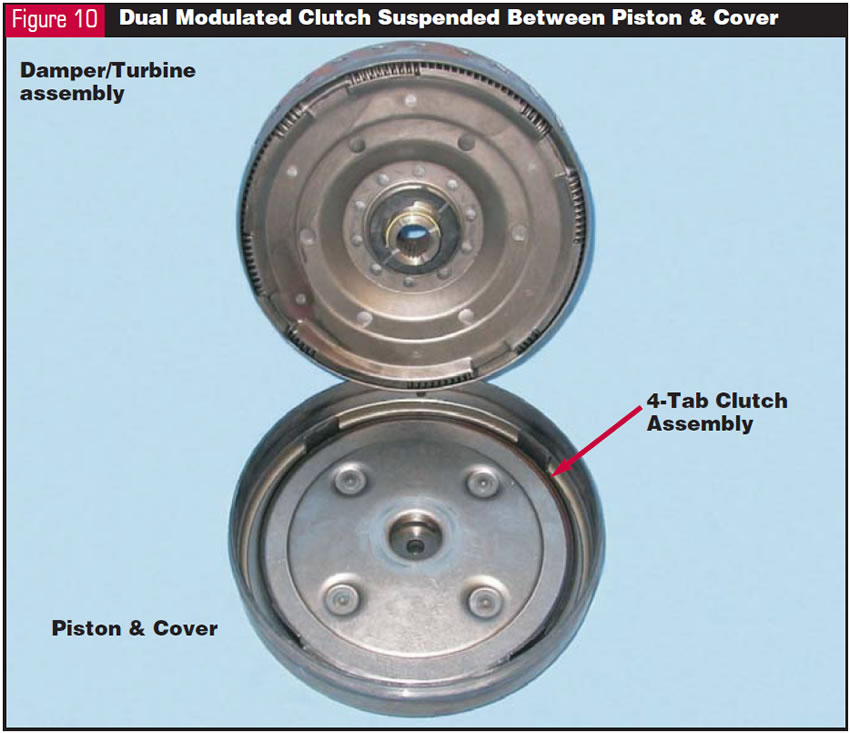

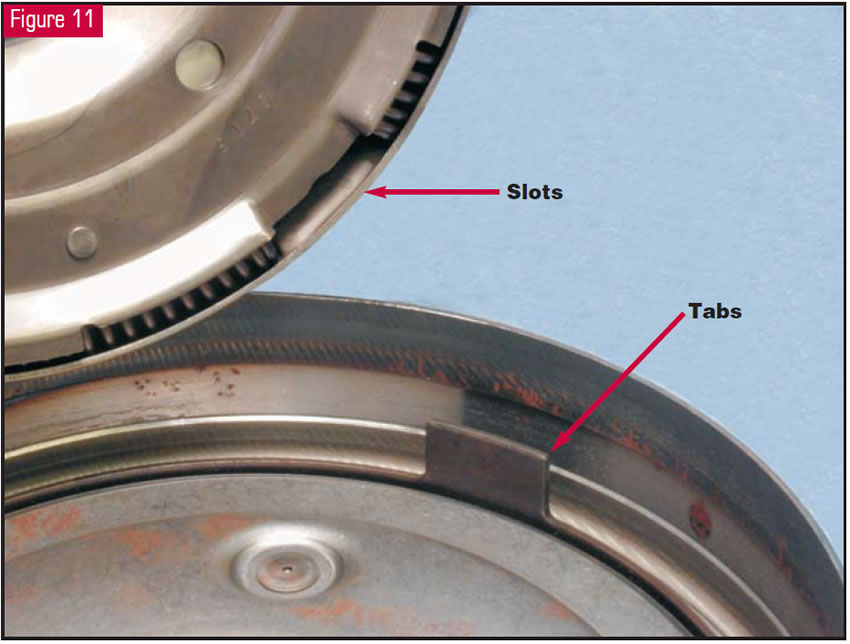

The apply piston has four ball-and-spring retainers that align and connect it to the cover and keep it centered in place (figures 8 and 9). The friction disc is suspended between the apply piston and cover (see Figure 10) with the damper/turbine assembly pictured above it. The four tabs on the rear side of the friction disc align and connect it with four slots in the damper portion of the turbine assembly as shown in Figure 11.

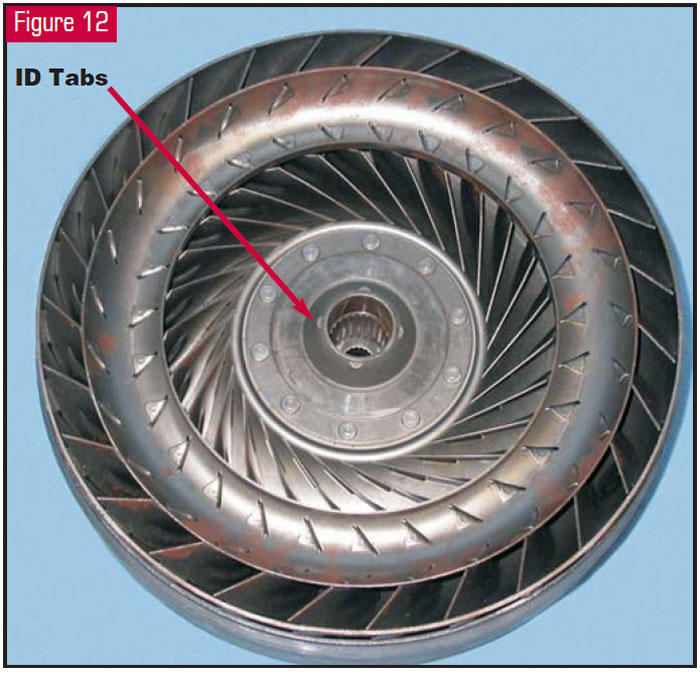

You may recall in 1993-94 when the AX4S converter turbine splines changed from 23 to 25. You could quickly determine which converter to use by looking down through the hub to see whether there were two tabs around the outside of the turbine spline area. The dual-clutch converter will have four tabs evident in this area (see figures 12 and 13). To ensure that you use the correct converter, you may want to look down inside the original core and compare it with the replacement converter before installation, provided it hasn’t already been replaced during a previous repair.

Last, I extend special thanks to Scott Kirkendall of Rostra Precision Controls for his assistance in providing the information on the solenoid control systems, and to Ken Cluck and Leon Keeney of Oregon Converter Co. for the information and use of the converters for my photographs.

Mike Souza is a technical-hotline specialist with the Automatic Transmission Service Group (ATSG).