Technically Speaking

- Subject: Fretting corrosion

- Unit: AW55-50

- Vehicle Application: 2002 Volvo XC70 AWD

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

The Merriam-Webster dictionary defines the noun form of the word “fret” to mean “the action of wearing away: erosion.” As a transitive verb it means “to eat or gnaw into, to make by wearing away a substance.” As an intransitive verb it can mean to “grate, wear, corrode, chafe or fray.”

The ASM Handbook on Fatigue and Fracture (Figure 1) defines fretting as: “A special wear process that occurs at the contact area between two materials under load and subject to minute relative motion by vibration or some other force.”

Fretting wear is usually associated with electrical contacts rather than non-electrical things, but fretting and fretting wear occur with both.

When it comes to electrical fretting, in the automotive industry this is usually the cause of what I call “ghost codes.” You have a solenoid electrical fault so you unplug connectors to check the solenoid and wiring and find nothing. You plug the connectors back and no more codes. This is usually caused by fretting corrosion. Because of vehicle vibration, electrical contacts in connectors can produce oxidized wear debris due to the small-amplitude fretting motion between the electrical contacts. This buildup of insulation is referred to as fretting corrosion and can interfere with the electrical circuit, causing the “ghost code” to set. In many instances this coating is difficult to see with the naked eye, and unplugging and reconnecting a connector cleans up the contacts enough to eliminate the problem.

A similar principle applies to metals. A great example of this coating developing that was once taught to me is tarnished silver. You polish it, yet the tarnish replaces itself to protect the silver. Oxidation of aluminum oxidizing and rusting of iron are due to the way in which their corrosion-resistant (protective) layer is compromised.

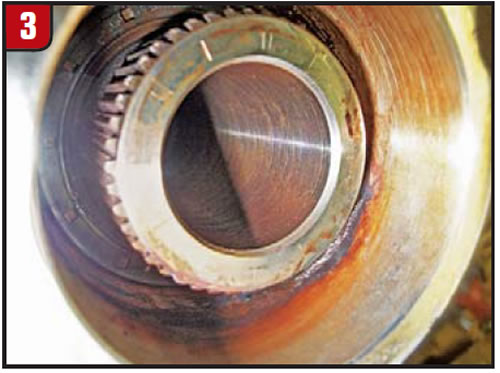

Fretting damage to steel can be quickly identified by a reddish-colored dust, as you can see inside the differential where the axle shaft rides in figures 2 and 3. These pictures were sent to me by Joey Campbell in Virginia from a 2002 Volvo XC70 AWD with the AW55-50 transmission. He had to use a pickle fork and a five-pound hammer to get that axle out of the transmission.

This is an extreme example of fretting damage with steel. This fretting problem is what causes driveshaft slip yokes and bolted flanges to produce ringing, clanking and popping noises; it can occur on just about any spline area and is also the explanation of how a rubber seal can leave a groove in a metal surface. The rubber seal rubs off the protective oxide layer. The oxide will then re-form to protect the base metal, and this repeated process is what causes the groove to form.

So when you are dealing with ghost codes, ringing, popping and clanking noise complaints, fret no more! Unplug and clean all electrical connections and apply some dialectic grease, dress and grease up all spline shafts for a fretless, faultless day.

Wayne Colonna, ATSG, Transmission Digest Technical Editor.