Tech to Tech

- Subject: Corrosion buildup in electrical connectors

- Essential Reading: Diagnostician

- Author: Brian Manley

Shedding some servicing ‘light’ on a difficult-to-diagnose phenomenon

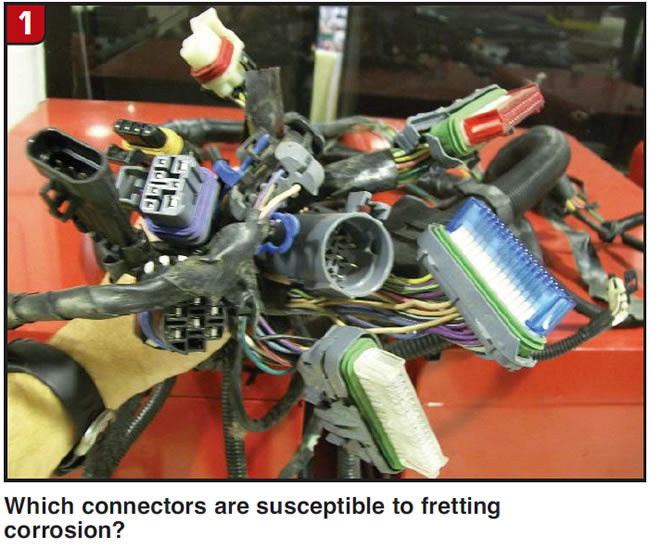

You may have heard the term fretting corrosion recently and wondered what is going on with this odd-sounding phrase. Fretting is defined by Merriam-Webster as “to pass away the time,” but it also means “to gnaw, chew or corrode,” and it is the second definition that can cause technicians to spend too much time experiencing the first. Fretting corrosion can cause time-consuming intermittent failures in a myriad of vehicle systems, and it can be difficult to find.

Delphi, which makes many of the automotive connectors for vehicles that we see every day, defines fretting corrosion as “a buildup of insulating, oxidizing wear debris that can form where there is small-amplitude fretting motion between electrical contacts. The oxidized wear debris can pile up enough at the contact spots that the electrical resistance across the contacts increases a lot.” Well, break out your favorite tube of dielectric grease and share these following examples of how this resistance can cause headaches for technicians.

The investigation that was closed in January 2009 revealed details of a safety recall of some GM vehicles that showed “a highly elevated incident rate of improper operation of the brake lamps” and that consumers would “use their brakes and discover that the brake lamps would not illuminate. Also, consumers report that the brake lamps would illuminate when the brake pedal was not applied.” Now, we have all seen recalls and bulletins like this before, but it is the root cause that I find interesting. In its letter to the National Highway Traffic Safety Administration, GM explained that “the primary cause of this brake condition was fretting corrosion (oxidation) of the connector pins on the body control module (BCM) that connect to the brake pedal position sensor (bpps). The corrosion prevents the BCM from receiving the correct signal voltage from the bpps.”

The official technical-service bulletin (08-05-22-009) says customers may experience intermittent brake lights, extended pedal travel to shift out of park, cruise control not functioning properly and setting of diagnostic trouble codes (DTCs). To correct the fretting-corrosion issue, the bulletin says to “unlatch the C2 connector from the BCM, and then apply dielectric lubricant with a one-inch nylon bristle brush to all of the C2 connectors, and then reinstall.” According to the bulletin, this “insulates” the connector from fretting corrosion.

My research showed that these lubricants reduce friction and wear, and to some extent they also shield the surface from air. The rate of resistance-building oxide formation can be decreased by cutting down available oxygen, combined with reducing mechanical deformation at the terminal connection.

I have to ask: How many intermittent conditions are caused by fretting corrosion? Bulletin No. 09-06-03-004B: Intermittent No Crank/No Start, No Module Communication, MIL, released in 2009, discusses the potential for all the above conditions being caused by “a buildup of nonconductive oxidized insulating debris known as fretting corrosion occurring between two electrical contact surfaces.” This is a wide-reaching bulletin that covers all electronic modules and systems of the vehicle and discusses the “potential” for fretting corrosion to cause intermittent issues.

Vibration, thermal cycling, micro-motion and poor connector or wire-harness retention are all listed as possible reasons for the fretting corrosion to develop.

In low-current signal circuits, this condition can cause intermittent conditions, such as the ones listed above; however, in high-current circuits, this may cause a permanent increase in resistance, resulting in a nonfunctioning circuit. For good reason, this bulletin begs the technician to NOT replace the affected control module if the condition is intermittent, or if the condition can be “fixed” by disconnecting and reconnecting the connector.

In a GM technical-service bulletin that revolves around proper fuel injector cleaning methods, there is discussion regarding the possibility of fretting corrosion causing drivability concerns. It says that “depending on how large the buildup of oxide is will determine how drastic the effect will be on the injector circuit. Worst case is a total loss of continuity in the connection resulting in P0200 (injector circuit fault) and P0300 (misfire) codes being set.” This is another case where oxide buildup creates a high-resistance circuit, resulting in insufficient current available to properly open the injector, resulting in unstable fuel delivery and ultimately a P0300 DTC.

The bulletin also states: “Keep in mind that a connection with fretting corrosion is unstable. Since movement causes fretting, any vibration may create a condition where the connection varies from an open circuit to a high-resistance connection to a good connection.”

What does fretting corrosion look like?

To help identify what fretting corrosion looks like, bulletins describe it as “little dark smudges on electrical terminals where the actual electrical contact is being made. In less severe cases it may be unable to be seen without a magnifying glass.”

How many of us have seen those dark little smudges on connectors and not given them a lot of thought?

The repair for this is just as in the first bulletin: a generous amount of dielectric grease brushed into the connector cavities, until it oozes from the edges when reconnected. Photos from the bulletin definitely show a lot of grease being used.

How can fretting corrosion be avoided?

Some manufacturers have TSBs about fretting; some have none.

Information about fretting corrosion on the Delphi connectors Web site says movement should be minimized between terminals, and terminals with higher contact force are less susceptible to this condition. In addition, gold- or silver-based connectors are more resistant to this condition than tin-plated connectors. In cases where we have no choice about the metallic content of our connectors, specialized contact lubricants can help delay the onset of fretting corrosion. We all need to make certain that we strap up those wiring harnesses after working in the engine compartment.

In my research on this topic, I discovered that not only does this condition cause annoying intermittent conditions for our customers, but fretting corrosion can be downright dangerous if it occurs in connectors attached to military equipment, communications satellites or other spacecraft. Very detailed stress tests – often funded by government agencies – reveal how different materials perform under various conditions and show that if you want a fretting-corrosion-resistant connection, gold is one of the best ways to go.

So, here is a question: When faced with a hair-pulling intermittent situation with a vehicle, should we stop and sell a special service that involves disconnecting all major connectors, applying dielectric grease and reattaching?

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. He can be reached at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.