Tech to Tech

- Author: Brian Manley

- Subject Matter: Drivability

- Vehicle Application: 1994 Ford Escort

- Issue: Compression variation

Customer’s love of high-mileage Ford Escort leads down a diagnostic path with lots of twists

I once had a customer who owned an old Chrysler that reminded me of the star in the movie “Christine.” Although the two cars were not quite the same year or model, I recall that my customer also named her old friend “Bessie.” When she dropped off her car she would say things like “Take good care of Bessie” and “Do whatever Bessie needs.”

I am remembering this because one recent customer also had a strong affection for his 1994 Ford Escort, and although he had not yet settled on a pet name, his old car held ties to his good ol’ college days and has been faithfully giving him years of “almost 40 miles to the gallon.” This would prove to be a tough relationship to break up.

Our customer said, “The engine just started shaking, and it is making a light ticking sound. It also does not have the power that I’m used to.”

Sounds like a simple diagnosis, right? That’s what I thought. After all, this was a 19-year-old car with more than 140,000 miles on a basic 1.9-liter engine.

We originally test-drove the vehicle to verify the shaking and lack of power, and we also heard a light ticking when it was idling and at lower engine speed. Even though this Escort far exceeded the average life expectancy of today’s vehicle, with gas currently at $3.50 per gallon, my customer dearly wanted to keep this little Ford on the road.

An initial power-balance test revealed that cylinder No. 3 was not contributing very much. In fact, it was virtually dead to the world. Our next test was a simple compression test, which revealed that all four cylinders – even though they had been pumping for almost two decades – were capable of 130 to 140 psi.

A quick scope test revealed that the ignition system was fully functioning, and we verified this with our spark tester. Next, we tested the injector trigger to our No. 3 cylinder, and the powertrain control module (PCM) definitely was requesting fuel. Suspecting a plugged injector, we flow-tested each injector and tested the pressure drop for each cylinder. All injectors dropped the fuel pressure evenly, about 8 psi on the wide-open-throttle setting (Figure 1).

Interesting: Cylinder No. 3 was not contributing, yet through our basic tests we had not yet found the root cause. Further suspecting an engine mechanical issue due to high mileage, we performed a running-compression test with the following results:

- Cylinder No. 1: 110 psi (increasing to 150 during snap throttle)

- Cylinder No. 2: 115 psi (increasing to 150 during snap throttle)

- Cylinder No. 3: 95 psi (increasing to 125 during snap throttle)

- Cylinder No. 4: 110 psi (increasing to 145 during snap throttle).

OK: So now I had what I was looking for. I had a test that pointed to a potential issue in cylinder No. 3, but I still did not see how a slight running-compression variation could completely kill my third hole. Over the years, I had found one worn-out rocker bridge on a big-block Ford, and I also caught two camshafts on General Motors engines that had given me low running-compression readings, leading me straight to the valve train. Today, I was not so certain.

I decided to perform an iATN search for this issue, and I found an intriguing thread that talked about three issues. One post talked about valve seats coming loose in the 2.0-liter engines, and yet another said that they had seen issues in the roller lifters residing in my 1.9 engine. Still, there was one interesting post that talked about camshafts with lobes that are pressed onto shafts, and warning about the perils of overlooking one of these lobes coming loose. I was now confident that I had to pull the cam cover and the rocker arms off for a further inspection.

I did remove the valve cover, and then I installed a remote starter switch so I could crank the engine over with the valve cover off. All the valves seemed to open equally, and so I started the engine with the valve cover off, with the same conclusion. I could not see any difference in valve-opening height between cylinder No. 3 valve and all the others. However, I continued with my disassembly, and Figure 2 shows what I found:

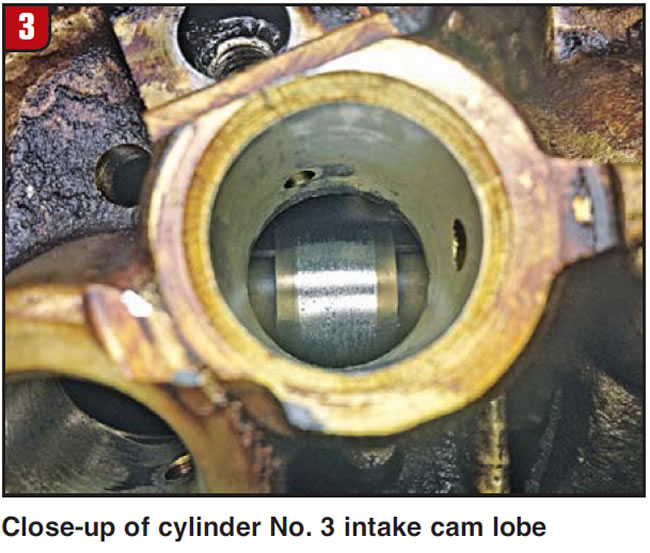

Can you see the difference between the intake and exhaust camshaft lobes for cylinder No. 3? Figure 3 shows a close-up of the intake lobe. The surface is noticeably rougher than all the other lobes, yet it is not worn down at all. It does not appear to have a “flat” cam. Rough to the touch? Yes. Worn out? No. I could also see no indication that the camshaft lobe had “walked” out of sync with the shaft.

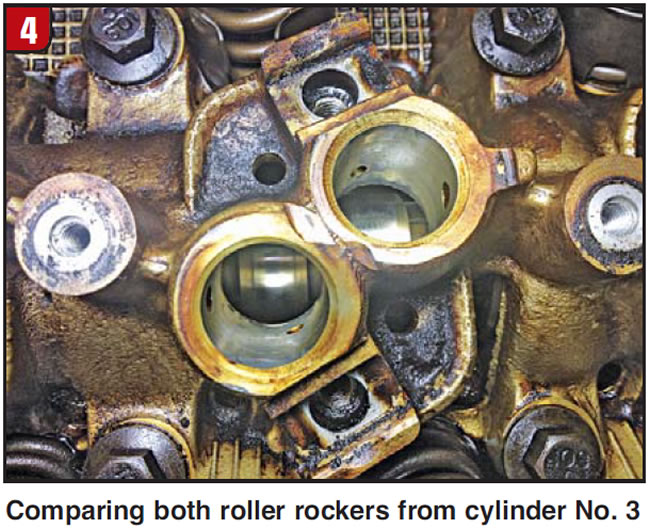

If we scrutinize the corresponding valve lifters for this cylinder, one can see the obvious difference in outward appearance. Although there is still not enough physical wear to indicate that the intake valve on cylinder No. 3 isn’t opening – yet I have running-compression data that points directly to this lobe – I believe that I am at least in the physical ZIP code of the root cause.

Figure 4 shows the wear on the rollers, and Figure 5 shows a slight variation in the overall height of the valve lifters, with cylinder No. 3’s intake lifter standing a bit taller than the rest. This lifter appeared to be “stuck” in a taller posture, as though the inside of the plunger had a failure.

Armed with all this information, we developed a quote for a new camshaft and lifters but also researched a rebuilt cylinder head and the option of a low-mileage used engine. Our customer had to wrestle with his inner love for the two-decades-old Escort, but ultimately this was the deathblow for the car, and he chose to invest his repair money into buying a new vehicle.

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. You can reach him at manley_brian@ hotmail.com.

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.