Clever Engineering

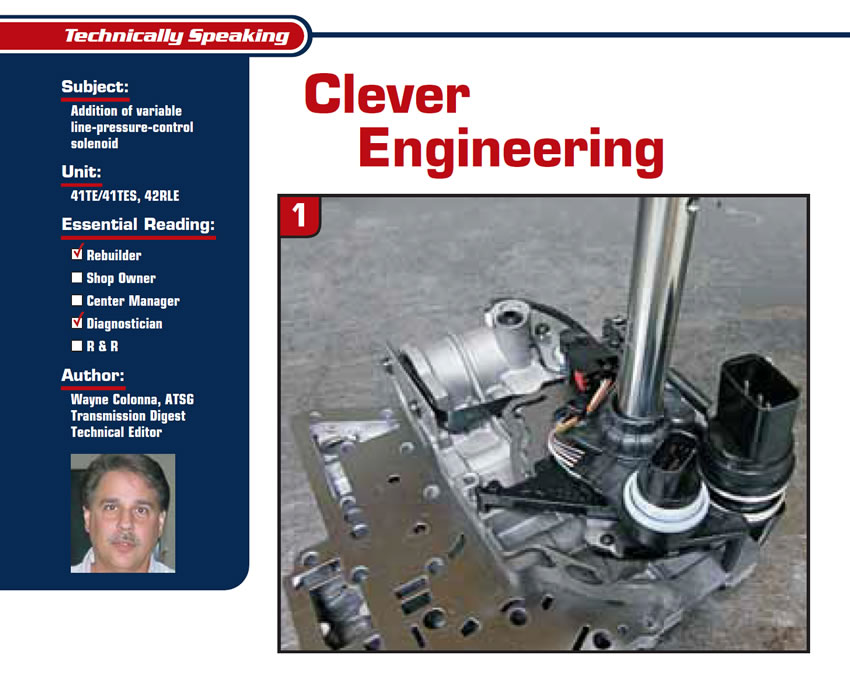

Starting with the 42RLE in 2005, followed by the 41TE in 2007, the engineers cleverly redesigned the valve body to accommodate a variable line-pressure-control solenoid and transducer. Figures 1 and 2 shows how these additional components are situated on the valve body with the 41TE transmission. This also required an additional pass-through case connector, resulting in changes to the case as well.

Mystery Noise in the ZF 5HP19/24

It’s not uncommon to hear customer complaints about a noise coming from a vehicle equipped with either a ZF 5HP19 or ZF 5HP24 transmission. The noise is most often described as a squealing or squawking sound and can be heard when the customer lifts his foot off the accelerator pedal. The sound is similar to that of a bad transmission pump and can be heard in any forward range but is most noticeable in first or second gear.

Circuit Interruptus

I recently had a vehicle in with a symptom that I thought would be an easy fix, only to have it take up several hours that I had not anticipated losing. Does this sound familiar?

The 1996 Chevy Tahoe had a customer concern of “No low-beam headlamps.”

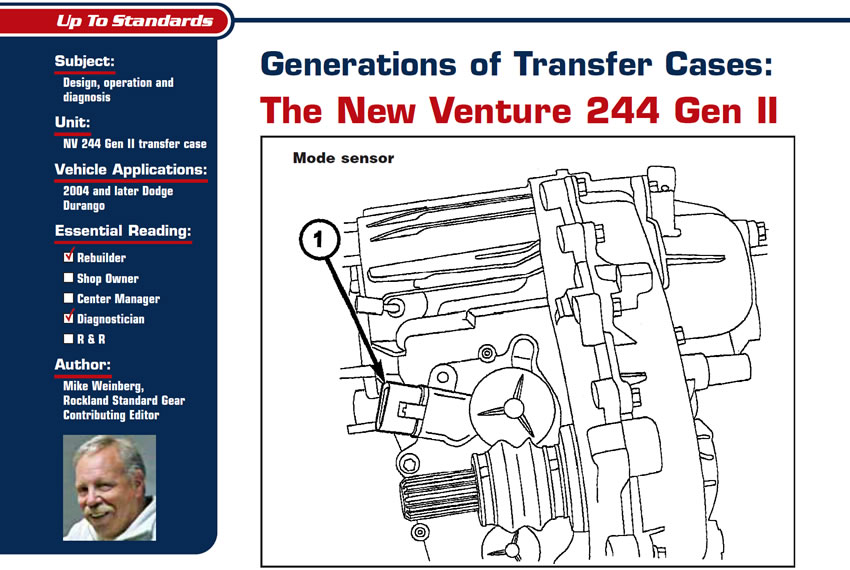

Generations of Transfer Cases: The New Venture 244 Gen II

With the introduction of the Dodge Durango to Chrysler’s SUV models came the 244 transfer case. From 2001 to 2003 the 244 transfer case was an evolution of the NV 242, which was a full-time/part-time unit.

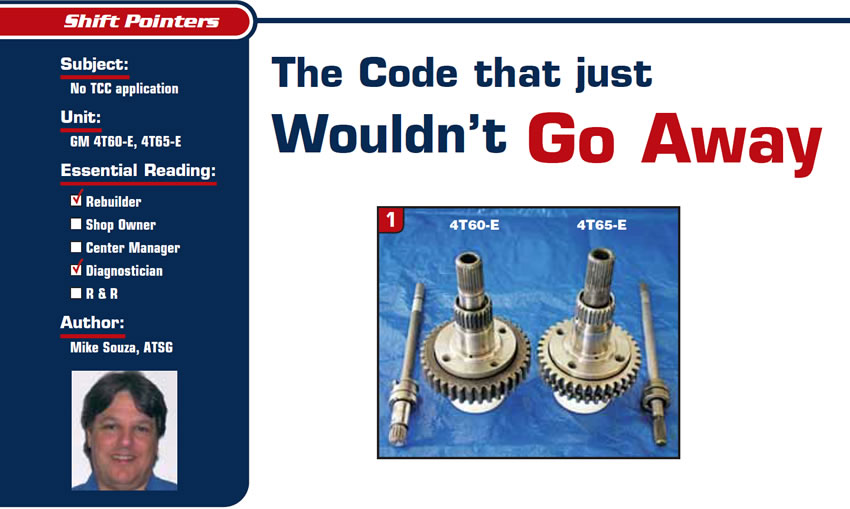

The Code that just Wouldn’t Go Away

This particular tech call was the usual 4T60-E or 4T65-E transaxle with the code P0741, “Torque Converter Clutch System Stuck Off.” It began as so many times before with the normal question, “Was this unit just rebuilt or is it coming back with this problem?” The next question was, “What repairs have you done to correct this problem?”

The Baker’s Dozen Attributes of a Highly Successful Automotive Business

How do you succeed in the automotive aftermarket these days? It’s simple; just be the best at everything. Have the best-managed and most technically accomplished shop, and you’re in – or are you? If you don’t market your business and use terrific sales techniques you’re back out again. Today your success is based on your proficiency in all aspects of the business.

Ins & Outs of Impeller Vanes and Weld Gaps

The movement of a vehicle relies on the torque converter’s ability to transfer the torque of the engine to the transmission (the beginning of the driveline).

April 2008 Issue

Issue Summary:

In the 2000 model year, some Mitsubishi F4A40/50-series transaxles were equipped with newly designed plastic-body solenoids.

A Mitsubishi or Hyundai vehicle may arrive at your shop with code P1723 or Mitsubishi code 54, or in limp mode (3rd-gear starts) with no codes.

Before or after overhaul, a Mitsubishi or Hyundai vehicle may exhibit a shudder or slip while being driven in reverse.

Before or after overhaul, a Mitsubishi or Hyundai vehicle may go to neutral while taking off in 1st gear or while making a 2-1 downshift during a stop.

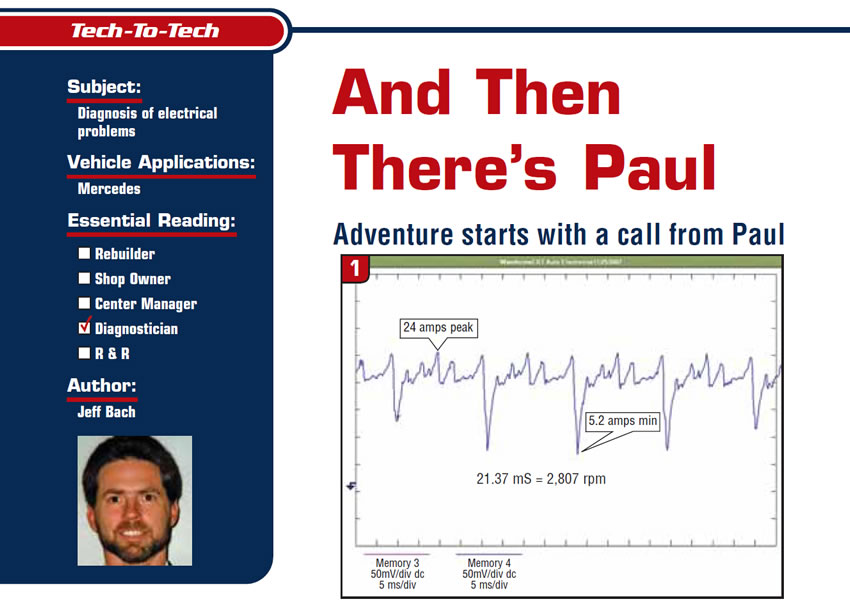

And Then There’s Paul

Paul’s list of problems with his car consists of some of the definitions that technicians (especially flat-rate techs) love to hate. Things like “The heat doesn’t always come out right” and “Sometimes the transmission doesn’t want to go like it should” or “The dash doesn’t light all the way up, and the radio needs a new speaker in the back right.”

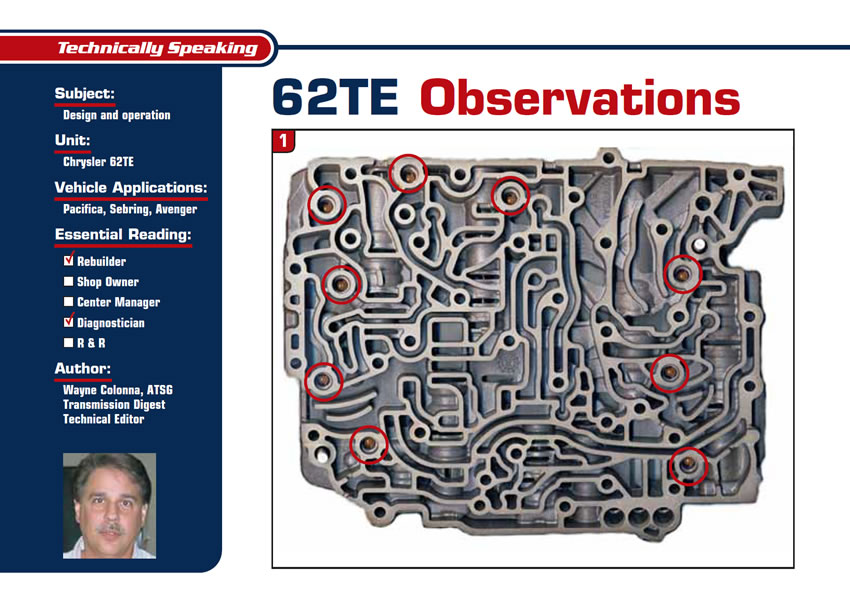

62TE Observations

In this article I thought I would share with you several of these observations that I covered in this Showpower presentation on the 62TE.

An Easier Way to Rebuild Planets

Many transmission shops are trying to stay ahead in an increasingly competitive market by offering warranties longer than the original new-vehicle factory warranty. Those shops putting their bottom line on the line have to pay attention to the planets if they’re not going to have a high rate of comebacks, but, because of the high cost, installing all new OEM planets is rarely a good option. The alternatives include reusing the original parts, finding what you hope are good used parts, using someone else’s rebuilt parts, taking a chance on new aftermarket parts, or disassembling, inspecting and reassembling planets in your own shop.

More Details

Producing a quality rebuilt torque converter is a major accomplishment. You have to perform many rebuild procedures correctly to end up with a quality finished product. Simply knowing the difference between the right and wrong way of doing a rebuild procedure doesn’t always guarantee success. It’s important to pay attention to the many details of the rebuild, and the proper use of shims is one such detail.