Up to Standards

- Subject: Design, operation and diagnosis

- Unit: NV 244 Gen II transfer case

- Vehicle Application: 2004 and later Dodge Durango

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

With the introduction of the Dodge Durango to Chrysler’s SUV models came the 244 transfer case. From 2001 to 2003 the 244 transfer case was an evolution of the NV 242, which was a full-time/part-time unit.

This unit used a mechanical planetary-type differential to distribute torque to the front axle when needed. The shift positions were AWD (all-wheel drive), 4W High, 4W High lock (full time), neutral and 4W Low lock ( full time). The part-time positions could be used on any road surfaces and operated only when there was a rear wheel slipping, which caused the mechanical differential to send torque to the front axle until shaft speeds equalized. The part-time 4W High lock and 4W Low lock part-time four-wheel-drive positions locked the differential and supplied a 50/50 torque split to the front and rear axles. These modes were to be used only for snow, ice or off-road situations where sand, gravel, mud or loose soil would allow slippage of the tires and prevent driveline windup caused by the difference in wheel speeds during turns.

The 2004 Durango came supplied with the NV 244 Gen II transfer cases, with Gen II standing for second generation. The 244 Gen II is an electronically controlled transfer case with full- and part-time modes but has NO two-wheel-drive mode. A mechanical planetary differential is splined to the mainshaft to distribute torque to the front axle as needed. A planetary with the input shaft as the sun gear provides a 2.72-1 low-gear reduction for off-road use. The shift positions for the transfer case are AWD (all-wheel drive), 4 Lock (part time), 4 Low and neutral. The vehicle is driven in all-wheel drive all the time and on any road surface unless the driver selects one of the part-time ranges (4 Lock or 4 Low), which are suitable for only off-road use. You may get questions from owners who have not read their operator’s manual as to why the front wheels may be powered, but this unit is always in all-wheel drive.

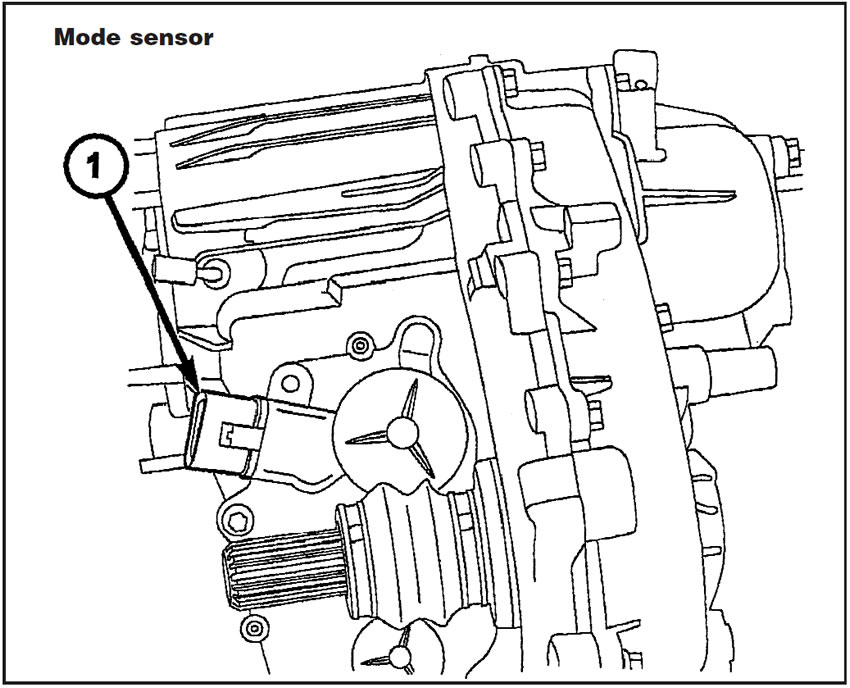

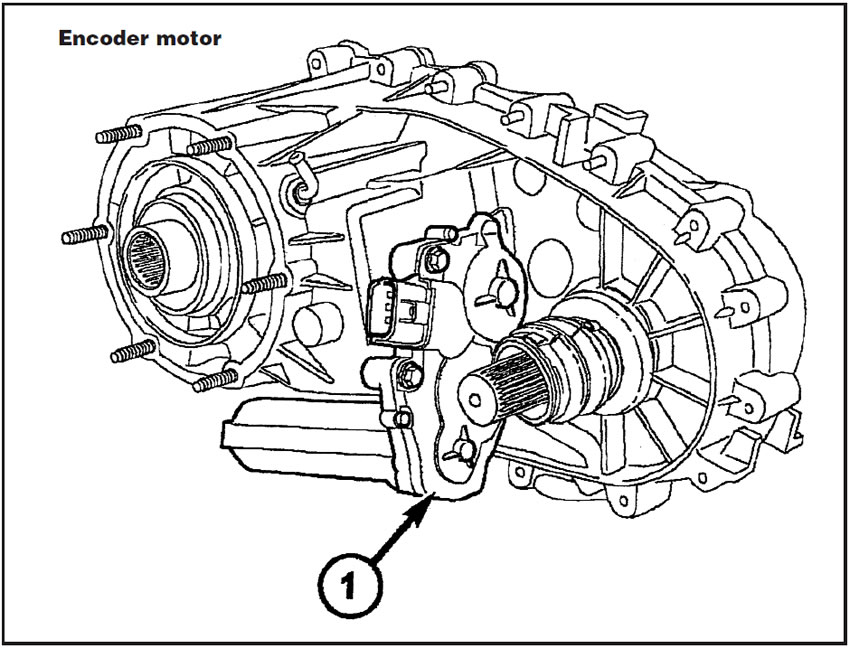

Shifts are accomplished through a dash-mounted shift-selector switch. The shift-selector switch sends an input signal to the transfer-case control module (TCCM) to effect a shift to change to another operating range. The TCCM, when receiving a signal from the driver, also gets input from the transfer-case mode sensor, which is part of the encoder motor mounted on the transfer case, and other inputs through the truck’s bus connection to decide whether parameters are correct for a shift to occur. If the parameters are within design specification the TCCM sends a signal to the encoder motor, which will rotate the shift sector in the transfer case, activating the mode and range forks to complete the shift.

The theory of operations for the mechanical transfer of power through the transfer case starts with the transfer-case input gear, which is splined to the output shaft of the manual or automatic transmission. The input gear is splined to the transfer-case mainshaft. The mainshaft drives through the planetary assembly and range sleeve. A drive sprocket on the mainshaft is splined to the differential assembly and drives a chain that is meshed with the front output shaft. The position of the mode fork and sleeve determines whether the front output shaft is driven by the mainshaft or through the planetary-type differential. The mode fork moves the mode sleeve and hub, and there is no synchronizer ring or mechanism in this unit.

These units are an advanced design of the 242 transfer case and suffer from some of the same diagnostic issues. They are extremely sensitive to mismatched or worn tires, tire pressures that differ among the four wheels, and vehicle loads that exceed GVW. If you have one of these units that will not shift through the 4 Lock range, save yourself some labor and make sure all four tires are the same diameter (within 1/4 inch), that all tire pressures are the same and that the customer does not have two tons of firewood in a half-ton truck before you remove the unit for inspection.

Another issue to be aware of is the immediate failure of the differential in the transfer case during emissions testing on a dyno or while the vehicle is being towed. Many states now require dynamic emissions testing using a dyno. Unless the dyno used will turn all four wheels at the same road speed, the transfer-case differential will go to the great scrap yard in the sky. If a customer comes in with a blown differential, check the inspection sticker or ask the customer whether it was inspected recently. Using a two- wheel dyno will destroy the transfer-case differential almost instantly.

These units have an internal oil pump supplying pressurized lube to the internal parts. This oil pump is contained in the rear case half, and the pump cover is bolted to the rear case half. It is always a good policy to inspect the oil pump and clean it of any accumulated debris. Chrysler manuals will tell you not to remove the bolts to the oil pump and that if the assembly is damaged the rear case half and pump must be replaced as an assembly. It is possible, and necessary in my opinion, to inspect the oil pump anytime internal repairs are necessary. Match-mark the pump cover before removal for proper re-assembly, and be sure to align the pump to the rear-output-shaft inner bearing and mainshaft before tightening the bolts on the pump cover. Pre-lube the pump, and rotate the mainshaft to make sure that the pump turns freely with no binding.

Diagnostic references

The mode sensor is the part of the encoder motor mounted on the transfer case where the harness connects. It is a linear analog position sensor that reads the rotational angle of the shift motor and sends a DC signal to the front control module. The sector rotation for the 244 Gen II units is -40 degrees to 20 degrees.

The forward control module supplies a five-volt signal (+ or -0.5v) to the mode sensor and monitors the position of the shift motor. The control module will monitor the position when the ignition is on and for 10 seconds after the ignition is switched off. Operational current draw for the mode sensor when operational will be less than 20 milliamps (mA). Needless to say, any current over 5 volts applied during testing will have you buying a new one. Shoot the guys who want to use 12-volt test lights everywhere. The control module will monitor the mode sensor every 2 milliseconds.

Sector angles compared with transfer-case position

- +20 degrees = 4LO position

- 0 degrees = Neutral

- -20 degrees = AWD position

- -40 degrees = 4 Lock position

Mode-sensor voltages

Note: The control module will consider mode-sensor voltages invalid if they are equal to or lower than the minimums or equal to or greater than the maximums listed below. The parameter voltages may change because of recalibration of the modules by the manufacturer.

- Encoder 4 Lock min = 4.26 volts

- Encoder 4 Lock max = 4.36 volts

- Encoder AWD min = 3.36 volts

- Encoder AWD max = 3.44 volts

- Encoder Neutral min =2.45 Volts

- Encoder Neutral max = 2.54 Volts

- Encoder 4 Low min = 1.48 Volts

- Encoder 4 Low max = 1.57 volts

- Encoder high-range limit = 4.51 volts

- Encoder low-range limit = 0.50 volts

Selector-switch operation

The Durango uses a rotary knob on the right side of the dash to allow the driver to select range and mode shifts of the transfer case. The TCCM will receive signals of various resistance depending on the knob’s position. Included in the rotary switch is a recessed area that contains a normally open momentary switch that shifts the transfer case in or out of the neutral position. You must use a pen or an opened paperclip to activate the switch, so drivers cannot accidentally hit neutral.

The mode-sensor supply-voltage pin and output pin will see varying amounts of resistance in conjunction with switch position. Before the connections to the individual position resistors are broken, the connection is made to the open/diagnostic resistor. The position resistor is open if the resistance is greater than 19K ohms between the mode-sensor supply-voltage pin and the mode-sensor output pin.

Resistance Values for the Selector Switch

- Shorted = <150 ohms

- AWD + neutral = 176-200 ohms

- 4 Lock + neutral = 190-216 ohms

- 4 Low + neutral = 199-226 ohms

- AWD (default) = 1,159-1,287 ohms

- 4 Lock = 2,259-2,503 ohms

- 4 Low = 4,820-5,334 ohms

- Open/diagnostic = >19K ohms

The encoder motor/mode sensor functions to move and lock the transfer case in a desired gear. The motor is a 12-volt DC permanent-magnet motor, a gear train and a motor brake coupled to an analog position sensor. These motors are shipped new in the AWD position, and the transfer case should be shifted manually on the bench to that position to install the motor. If you wish to change the motor position the motor brake must be released first. The motor brake is a solenoid contained in the housing that, when energized, releases and permits the motor to rotate. The motor brake can be energized on the bench with a nine-volt battery to pin through pin 7. If you wish to use 12 volts, max amperage to the solenoid should not exceed 1.2 amps.

The encoder motor will receive a pulse-width-modulated voltage from the TCCM at pin 6 during normal operation (ignition on). The motor brake must always be released for two to five seconds before and after a shift. If the TCCM shows a motor-brake DTC the motor brake must be engaged. The TCCM receives a constant signal from the mode sensor that indicates the relative position of the transfer-case shift sector. The TCCM will switch voltage polarity to change the encoder motor’s direction of rotation.

The NV244 Gen II transfer case is a relatively simple device mechanically, with electronic controls and a mechanical differential to distribute torque to the drive axles. You should have no trouble diagnosing and repairing these units if you understand how they work and pay attention to factors outside the unit, including the electronics, tire sizes and wear, tire pressures and vehicle overload conditions.