Torque Converter Tech Tips

- Author: Ed Lee

It’s not uncommon to hear customer complaints about a noise coming from a vehicle equipped with either a ZF 5HP19 or ZF 5HP24 transmission. The noise is most often described as a squealing or squawking sound and can be heard when the customer lifts his foot off the accelerator pedal. The sound is similar to that of a bad transmission pump and can be heard in any forward range but is most noticeable in first or second gear.

In the early 1980s, transmission technicians had a very similar noise issue with GM’s 700-R4 transmissions. The noise sounded the same but was heard under different conditions. The noise in the 700-R4 became audible when the vehicle was accelerating heavily. The technicians were able to isolate the noise by operating the vehicle in the D or 3 range; when the transmission was in those ranges the noise disappeared. Placing the transmission into the D or 3 range prevented the transmission from advancing past 3rd gear, but, more important, it applied the overrun clutch for engine braking. Since the overrun clutch holds the same driving component that is held by the forward sprag, it was safe to assume that the noise was coming from the forward sprag.

Unfortunately, the noise in the ZF 5HP19 and 24 transmissions was much more difficult to diagnose, even though it also was eventually traced to a sprag. The sprag that was causing the noise couldn’t be isolated because it was in the torque converter, not the transmission. The only component that the sprag held was the stator. Eventually, the noisy sprag was found by a process of elimination.

Frank Kuperman, from Redline Torque Converters in Phoenix, recognized the urgency of customer complaints about the noise because he knew that the R&R time for the Audi ZF 5HP24 transmission was more than 16 hours. Frank reasoned that the noise occurred when the customer lifted his foot off the accelerator, and this was the same time that the sprag in the stator started to freewheel. Since the sprag’s inner race is splined to the stator support and does not rotate, the noise had to be coming from the contact point between the sprag and the inner race.

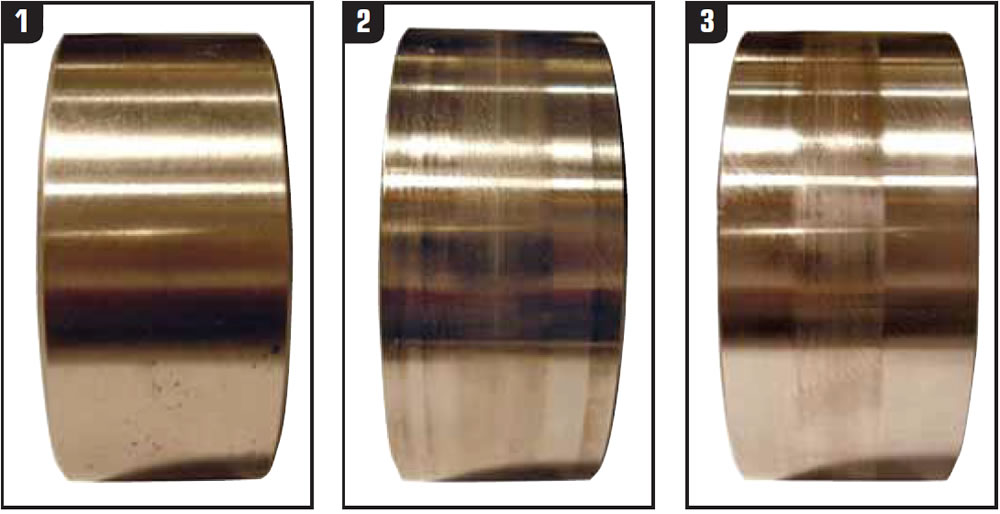

Figure 1 shows a new inner race. Figure 2 shows a used race that does not make any noise. Figure 3 shows a used race that is noisy. There is very little visual difference between the quiet and noisy inner races. The best way to check the surface of the race for conformity is to use your fingernail or a scribe. No part of the race should catch on your fingernail or scribe.

The traditional method of checking the sprag’s ability to function will tell you only that the sprag will lock and freewheel. This method will not identify any noise issues, so take the extra time and visually check all sprags.

Special thanks to Frank Kuperman of Redline Torque Converters in Phoenix for his help in solving this mystery.

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com. ©2008 Sonnax Industries Inc.