One of our ATSG members, Bob at Trans Tek, recently shared with us an experience he encountered with a 2011 GMC 3500 Mini School Bus with a Duramax diesel engine in front of a 6L90 transmission. It came in to the shop slipping, along with having no second or sixth gear. After the transmission was removed, during the initial teardown process, he noticed that the unit was exceptionally clean.

There was no evidence of converter clutch failure or pump damage. But once the center support assembly was removed (which houses the 2-6 clutch), the secondary cause to the complaint was identified. The lugs above the groove of the snap ring used to retain the 2-6 clutch assembly were blown off (see Figure 1, above).

To replace this support now required determining what caused these lugs to break the way they did in the first place. Bob’s diligent search discovered a severely worn pressure regulator valve and bore. It apparently had worn in such a way that caused enough of an uncontrolled pressure spike to snap these lugs off the housing. Changing the center support, reaming the bore and installing and oversized PR valve completed the repair.

But this was not the only incident he shared with us concerning reaming the pressure regulator valve and bore. The next was with a vehicle with a 6R80 transmission.

Reaming with a dull reamer, without enough lubricant, or at the wrong speed can easily compromise the ream. The result can be that the valve will get stuck in the fully stroked position, or not stroke completely, due to the incomplete ream. When the valve is stuck in the fully stroked position, low line pressure will occur, burning clutches. When it is not stroking completely, this can cause high enough pressure to crack pistons. Figures 2 through 4 show three different pistons cracked from the same transmission because of the PR valve not being able to fully stroke. The damage to the transmission was immediate.

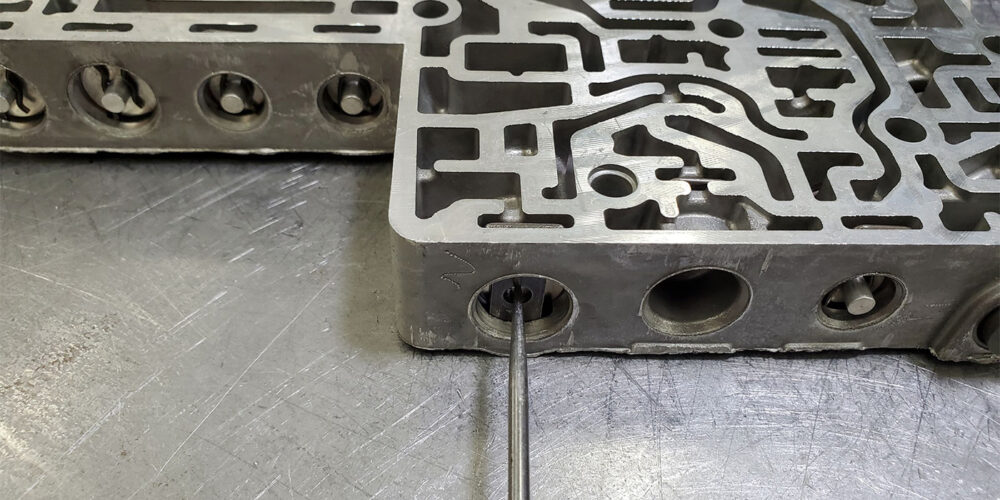

Here’s a quick method in checking the PR valve after a ream, aside from doing a physical inspection. Once the valve assembly is installed into the valve body, use a pick to stroke the valve from the retainer end of the valve as seen in Figure 5.

You will quickly notice if the valve is incapable of stroking completely, which will cause this type of damage. If it does fully stroke and then stick, there will no longer be any spring tension on the valve and there will be a gap between the retainer and the valve’s end cap sleeve. There may not be any broken parts when this happens—just burned parts.

Read more stories from our Technically Speaking column series here.