TASC Force Tips

- Author: Jim Dial

- Subject Matter: Secondary regulator valves

- Issue: Understanding hydraulics

An understanding of hydraulics is essential for properly diagnosing and repairing transmission problems. This article is one of a series by Sonnax exploring how valves and hydraulic circuits work and what results when they quit functioning correctly.

The secondary regulator valve is primarily used in Aisin AW variations, including Toyota/Lexus U140, U150, U660, U760, A760, A761, A960, AB60 and VW/Audi 09G and 09D, just to name some current applications.

This valve has been around for a long time, even back to the old A40 non-lockup models. The secondary regulator valve controls torque converter release and apply pressure, as well as lubrication pressure and balance pressure. It basically limits these pressures to approximately 100 and 120 psi, depending on vehicle application. This prevents TCC release and apply timing issues, as these circuits are controlled to a maximum pressure.

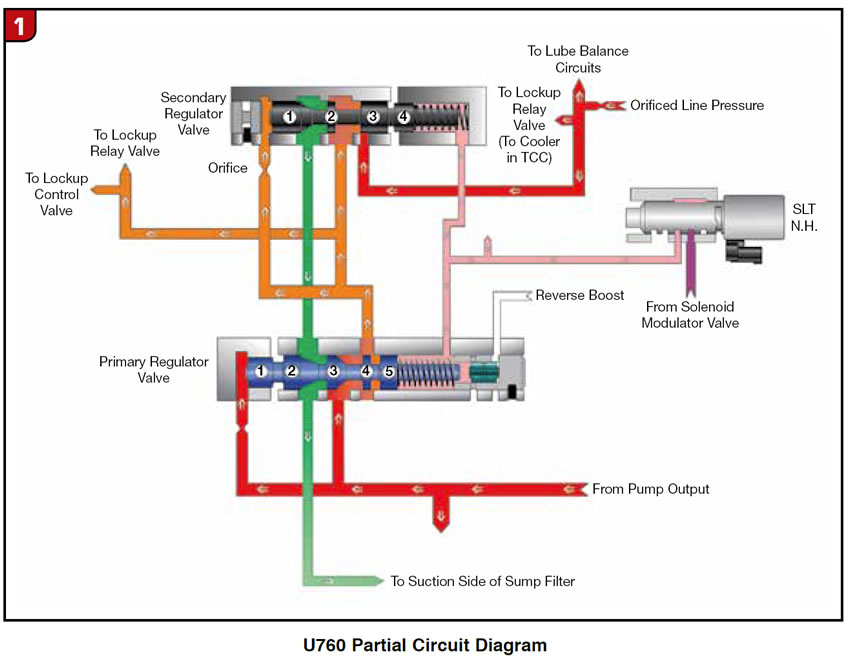

Looking back at other OE transmission applications, some manufactures use a torque converter limit valve on the release side of the torque converter circuit and then use regulated line pressure to apply the clutch. Other OE applications will have a TC limit valve on the release side and a TC regulator valve on the apply side of the torque converter clutch circuit. The use of the secondary regulator valve basically handles both release and apply pressures through one valve in the Aisin family. Figure 1 shows a partial oil circuit diagram of the secondary regulator valve on the U760 and its connection to the primary regulator valve.

Figure 1 — U760 Partial Circuit Diagram

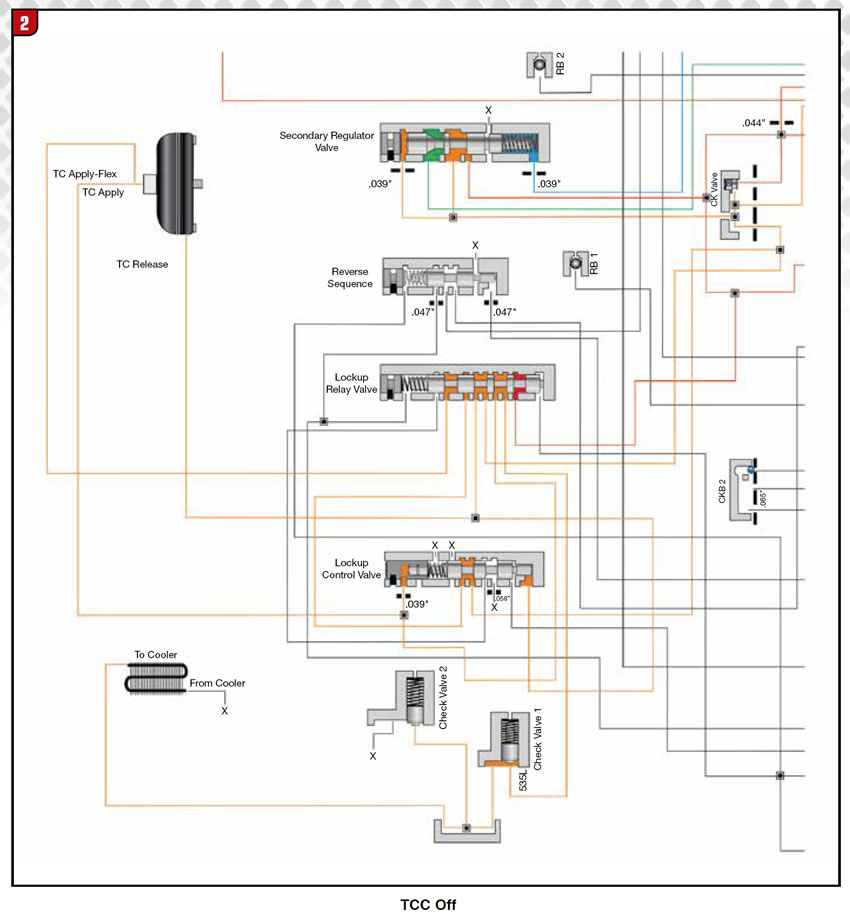

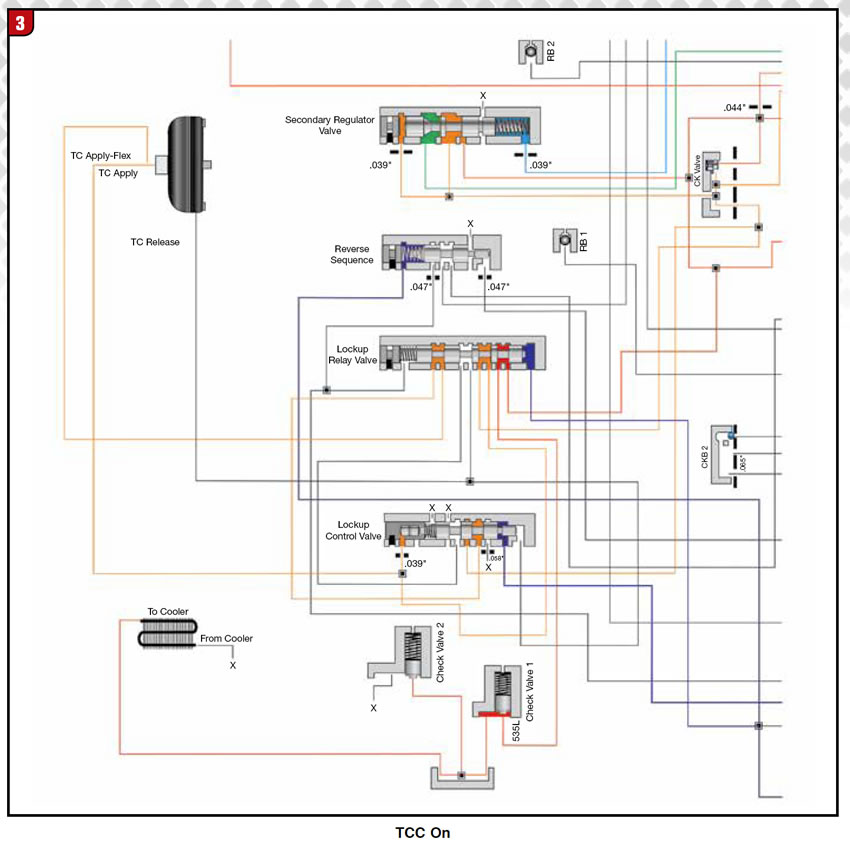

Pump output pressure is fed to the primary pressure regulator valve. The primary pressure regulator valve regulates this pressure through the balance feed connected to valve spool 1, the spring force, and SLT output pressure from the SLT solenoid, which acts as the pressure control solenoid on the spring side of spool 5. Regulated line pressure from the primary regulator valve is fed in between spool 3 and 4, which is connected to the secondary regulator valve between spools 2 and 3. This same feed pressure is sent to the balance side of the secondary regulator valve at spool 1. The spring force and SLT pressure at the spring side of spool 4 control secondary regulator valve pressure. Regulated pressure from the secondary regulator valve is fed to the lockup control valve and lockup relay valve. These valves control the switch from TCC Off (Figure 2) to TCC Flex to TCC On (Figure 3).

Figure 2 — TCC Off

Figure 3 — TCC On

These are the three torque converter clutch modes available on the U760 transmission. Spool 4 of the secondary regulator valve has a connection from orificed line pressure to the internal lubrication circuits and a “To Cooler” connection that is fed to the lockup relay valve to help keep transmission fluid temperature down.

Problems in the secondary regulator valve lineup can be related to the following complaints: engine stall or stumble from the loss of TCC release pressure; torque converter slip; TCC apply chatter/shudder or no torque converter clutch application, which can create numerous diagnostic trouble codes. Lubrication and overheat issues also can stem from problems in this area.