Tuning a vehicle to optimize its performance is nothing new. This customized process is used to provide fuel efficiency and improve other driveability concerns. Tuning for torque is especially desirable by diesel owners.

Those who are proficient at tuning know that the transmission will need serious upgrades to survive the increased force it will receive from the crank, through the converter and to its internal components. Those who are tuning amateurs blow out their transmissions by ignoring the physical path torque travels to get to the ground.

With so many Dodge diesels on the road, transmission shops see this oversight frequently, especially with 68RFE transmissions. There are some very cool tuning tips that a knowledgeable tuner can use on a transmission to help it survive. It seems that most tuners know what to do with the engine but not the transmission; but even when they do have some knowledge about transmission tuning, this doesn’t exclude upgrades the transmission will need to have for it to hold up to the increased torque.

In addition to these benefits, transmission tuning can also be used to diagnose problems. I recently had the opportunity to work with Craig Sarokoff at AACTION Transmission in dealing with a 2013 F-250 4WD Super Duty 6.7L Diesel using the 6R140 transmission. It came in with a delayed engagement into reverse. A scan tool revealed that no codes were set. All engine load parameters were reporting correctly. Nothing was seen as wrong with the Transmission Range Sensor or Turbine speed sensor either. A line pressure gauge was then installed and showed 90 PSI of line pressure as specified. When the harness was disconnected, line pressure went up and the engagement into reverse was immediate.

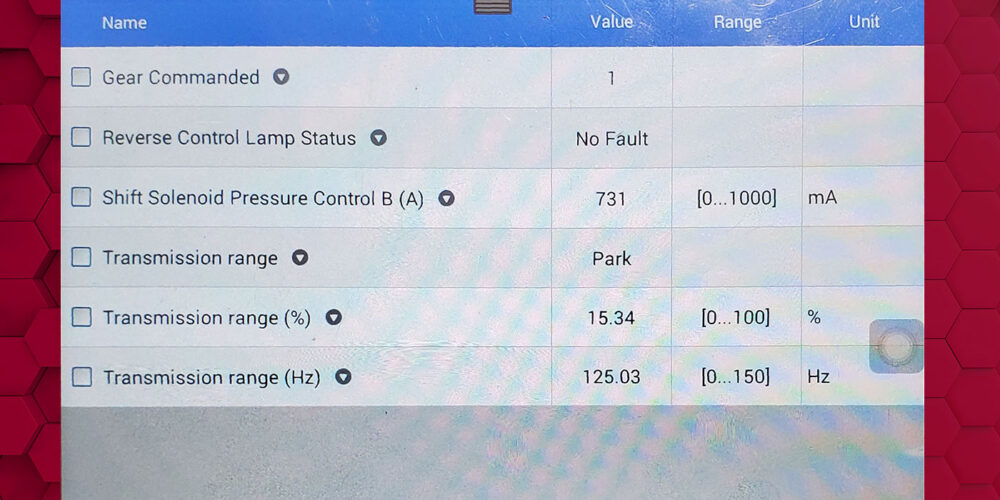

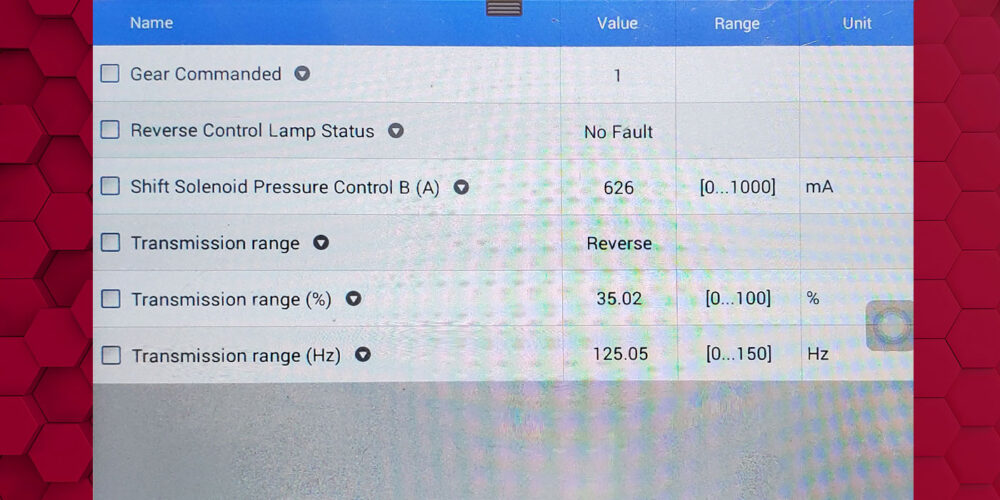

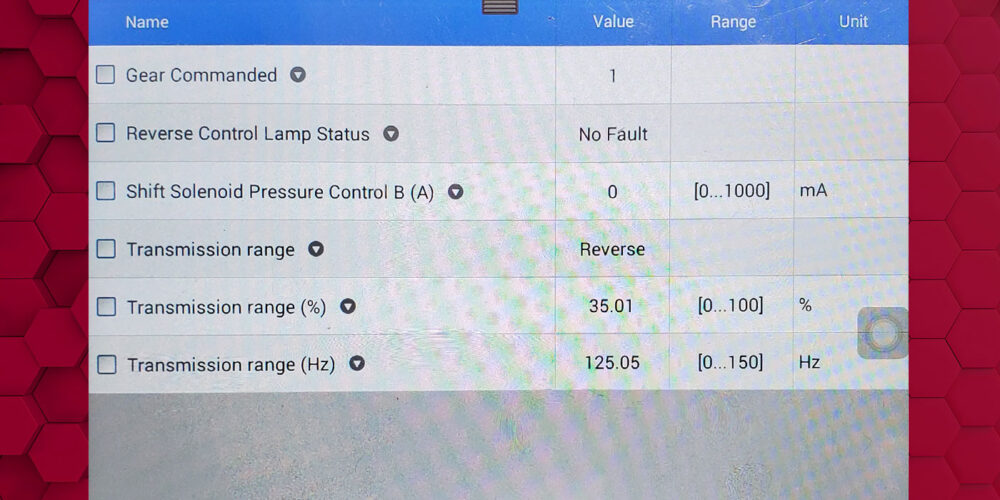

With the L/R clutches being applied upon startup in Park, only the 3-5-R clutch needs to apply to make reverse. The scan tool was then used to monitor the Normally Applied Shift Pressure Control Solenoid B (SPCS-B) to see how long it takes for the 3-5-R clutch to apply. Figure 1 (above) is a view of the scan tool in Park showing 731 mA on the solenoid keeping the clutch off. Figure 2 shows when reverse was selected, which is frame 4 in the movie recording of this shift engagement event.

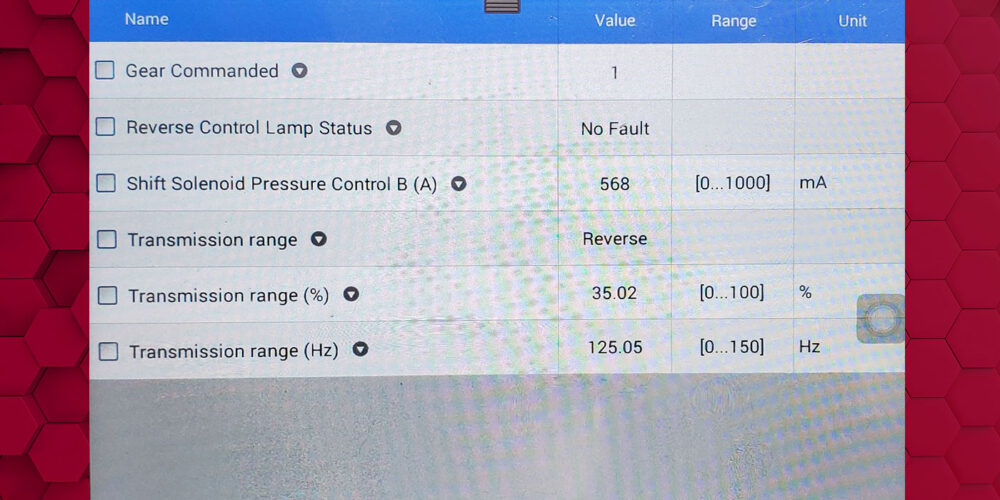

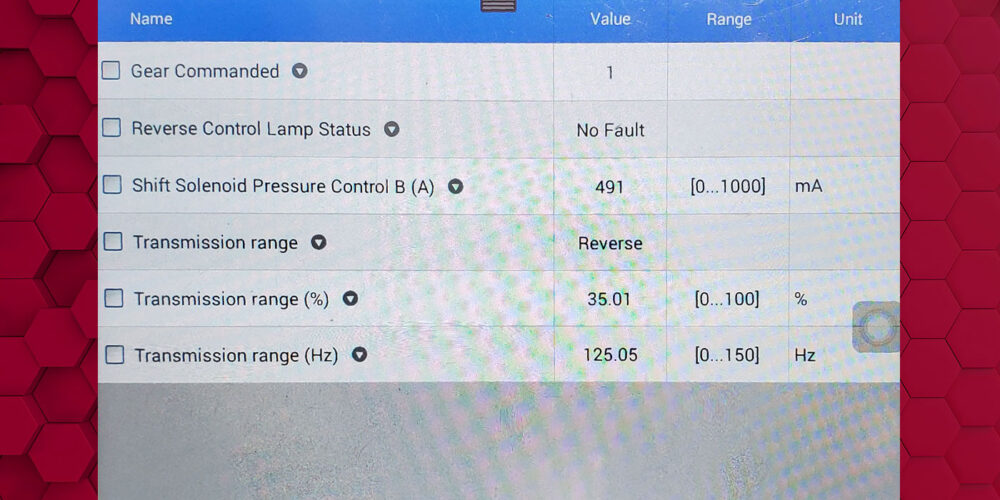

The mA drops to 626 as it begins to apply the clutch. Frame 5 in Figure 3 now shows 568 mA. Frame 7 in Figure 4 shows 491 mA. By frame 9 the mA went to 0. It took 4 seconds from frame 4 to frame 9 before the transmission finally engaged into reverse.

With no codes present, all necessary input parameters functioning correctly, and proper line pressure, it appears that there is something wrong with the computer causing this delay. TSBs were investigated to see if there may be a program update to resolve this issue, but none were found other than a drain back problem affecting forward and reverse.

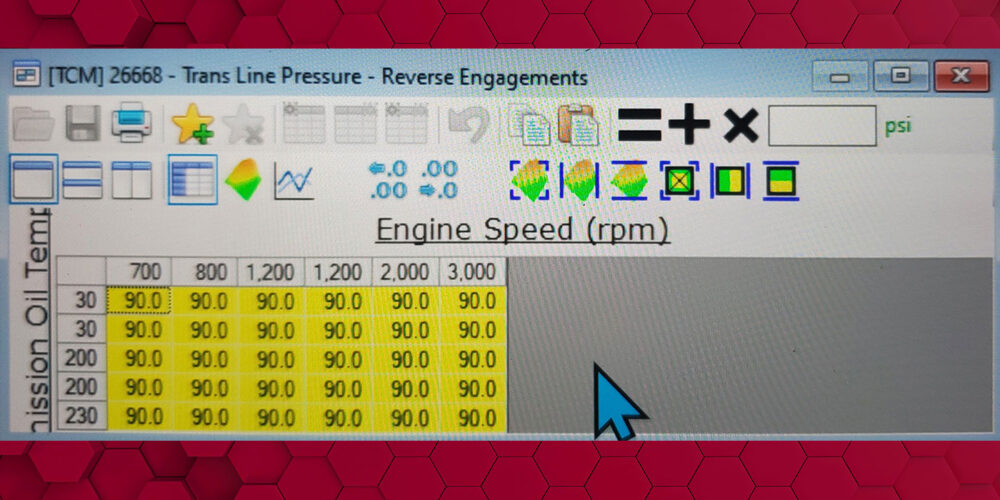

At this point Craig hooked up his HP Tuner. He had been working on this with Chris Pedone from Brevard Discount Transmission and Auto Center, and had gotten some great tips from him. Figure 6 shows the factory command line pressure being set at 90 PSI during the garage shift into reverse.

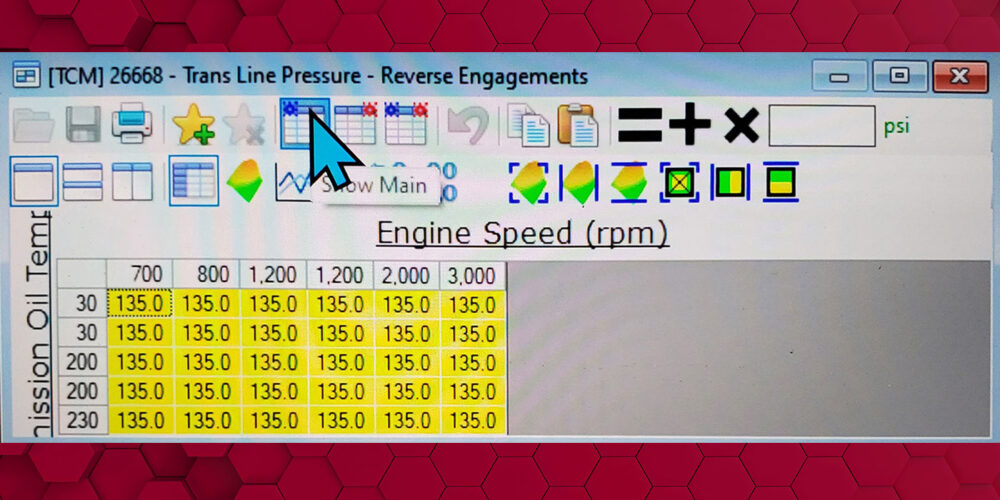

With the HP Tuner, this was changed to 135 PSI to see if the engagement would occur sooner (see Figure 7).

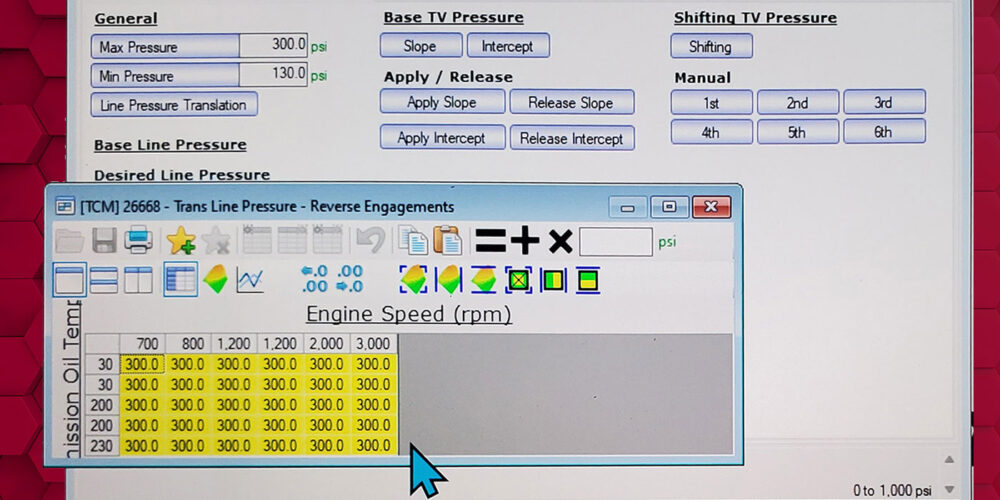

The pressure gauge revealed that line pressure did go to 135 PSI, but the engagement was still delayed. Line pressure was then set to 300 PSI as seen in Figure 8.

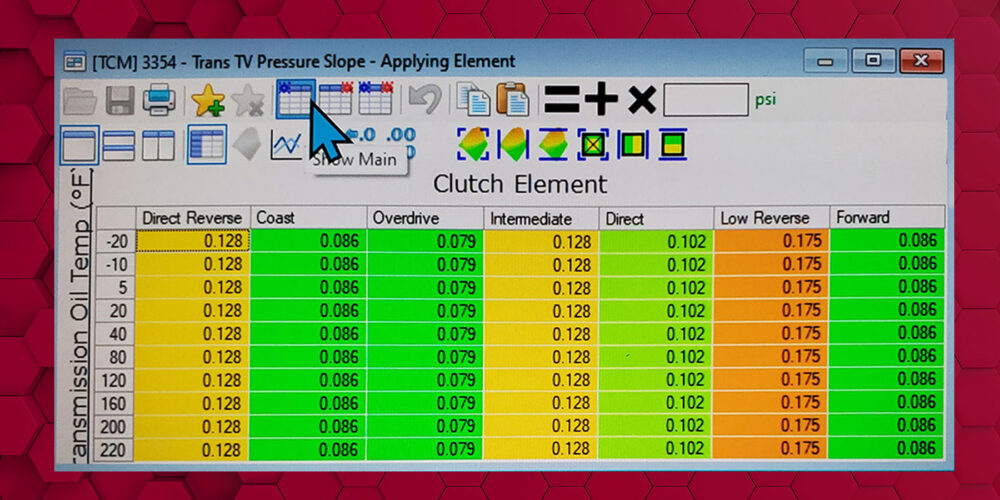

The pressure gauge confirmed that line pressure was at 300, yet the four-second delay remained. This was because the driver in the computer was slow in turning off SPCS-B to apply the 3-5-R clutch. So, the technicians played with the slope time in an attempt to resolve the problem (see Figure 9). This did not change what the computer wanted to do either, confirming that the computer was defective and needed to be replaced.

The bottom line is that tuning is undeniably an important skill to learn. There is a learning curve, but it is well worth the money and time. One word of caution: An early and necessary step in the learning curve is to be trained, especially when it comes to tuning engines. If this step is not taken, a simple stroke of a key and your engine will become molten metal. Not a pretty picture. Greg Banish is a great guy to learn from when it comes to this. He has plenty of training available for those seeking to learn.

Admittedly, there is not too much training available for tuning transmissions. So there is effort involved in acquiring the skill; but the payoff is amazing. Those who have learned this skill are making their units last. The 6L80/90 is at the top of that list.

Since I mentioned 68RFE earlier, for stock builds, here are a couple of changes that will make this unit last is a longer: hold time on the L/R clutch before a shift into second takes place, and alter the overdrive clutch holding pressure.

Being tuned in is not only a great way to make your transmissions better, but you can also diagnose with it to know that when you buy another computer, it is going to fix your problem.

Read more stories from our Technically Speaking column series here.