It was a dark stormy night… well, not really; it was just an ordinary Tuesday.

On that ordinary Tuesday, a customer came into our store very distraught. He had been to several shops with concern of feeling a shudder while driving his vehicle uphill. None of the other shops or the Toyota dealership could give him a definite answer to the cause of his concern. They all said it was possibly the torque converter, but they were not 100% sure.

His vehicle is a 2005 Toyota 4Runner with the standard A750 transmission. The vehicle has a dealer-installed lift kit, it has oversize tires (LT285/70R17), and the OEM tire size is P265/65R17. No other modifications had been made to this truck. The customer complaint was a brief shudder (“stutter” was the word he used) while accelerating up a hill.

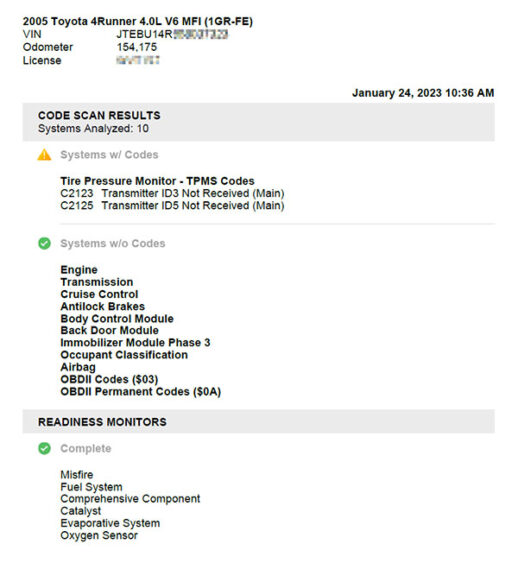

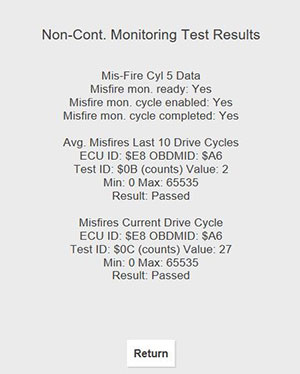

I took the vehicle for a road test and was able to verify his concern; I felt the shudder in the seat and floor of vehicle. The shudder did not feel like an engine misfire or typical torque converter clutch shudder; however, something was there. I performed a vehicle scan and found no codes associated with the customer’s concern. There were a couple of TPMS codes present, but on a vehicle of this age I could not see them having any effect with this issue. I verified that all readiness monitors had been completed. (See Figure 1).

I suspected a possible concern with the torque converter clutch operation due to the tire size being incorrect. My theory was that the torque converter clutch was being commanded on and off to maintain power on uphill acceleration, and this might be a “new normal condition” after the vehicle modifications were made. I road-tested the vehicle with the scanner attached and monitored torque converter clutch operation to prove or disprove that theory.

I verified that the torque converter clutch was being commanded on at the correct speed and I also used the GPS app on my phone to verify that the speedometer was reading correctly. I noted that I did not see any engine RPM fluctuation per the scanner PID nor the truck’s tachometer. While on the road test, I was able to detect that the shudder also occurred while driving on a flat road under light acceleration, just not as noticeably as when driving uphill. I also discovered that when the TCC was applied, if I lightly tapped the brake pedal to disengage the TCC, the torque converter clutch did release but shudder was still present.

I went back to the shop and re-scanned the vehicle. There were still no DTCs, and all monitors were completed. I now decided it was time to put on my detective hat and start digging for the clues to this mystery.

While being a little perplexed by this vehicle and after consulting all my other sources of information, I remembered the first rule of transmission diagnosis: “The automatic transmission cannot operate normally if the engine does not operate properly.”

I turned my attention to the engine operation. While monitoring the engine data in the stall, I found no evidence of misfire or incorrect operation of any sensors. The throttle position sensor and engine RPM were all reading as normal throughout the throttle sweep. I drove the vehicle again with the scanner attached and monitored the engine operation. All operation seemed normal, but the shudder was still present. I monitored the vehicle speed sensor looking for any erratic readings; all operations were normal. I re-checked for codes and there were none. I then road-tested vehicle once again with the scanner and watched for completion of the misfire monitor.

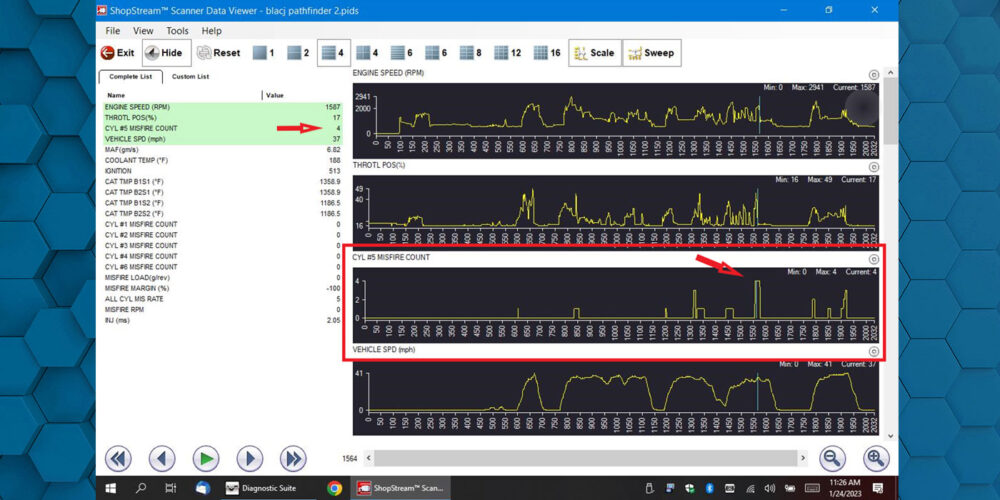

While driving and performing the misfire monitor road-test, I discovered a slight engine misfire from the number five cylinder, but all the other cylinders showed no misfires occurring. The number five misfire was occurring at the same time as the shudder. (See Figure 2).

This begged the question: Why did the vehicle scan and monitors show no concerns?

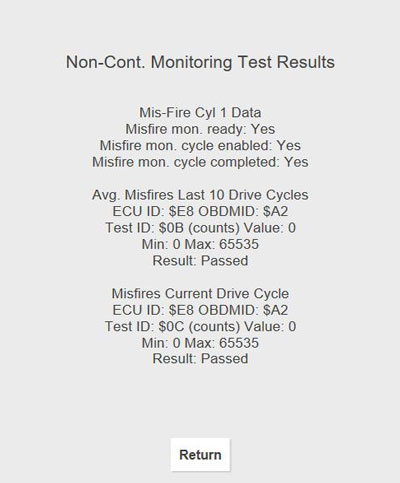

I went to the generic engine test section of the scanner, and I checked the seldom-viewed MODE6 data and examined all six cylinders’ misfire data. Cylinder one data was typical of all cylinders except number five. (See Figure 3). Number five showed a misfire count of 27 misfires. (See Figure 4.)

So now the question was, why no check engine light or diagnostic codes? I did more research and found that my definition of the number five misfire does not fit the criteria for a misfire A, B or C. Therefore, remember that when diagnosing a concern, while scan tools and PID data are great diagnostic pieces, sometimes good old-fashioned, “seat of your pants” diagnosing helps get to the bottom of things.

We told the customer the results of our diagnosis and recommended a possible tune up. We referred him to a local shop we work with which is known for very good drivability technicians. The customer took the vehicle to them and got new spark plugs and the injectors serviced, and the concern was gone. He called us about a week later to thank us for not just replacing the torque converter like two other shops had recommended to him. The truck is running smoothly, and the customer was pleased with our service.