Up To Standards

- Author: Mike Weinberg, Contributing Editor

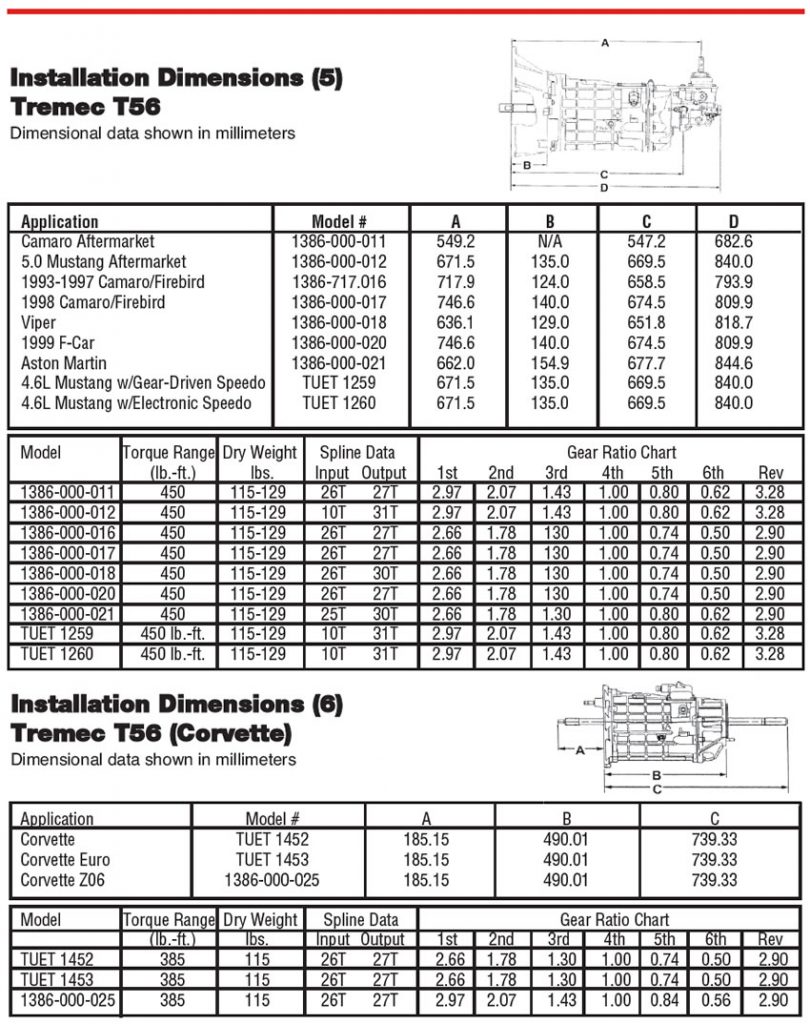

In the 1993 model year GM introduced the T56 six-speed transmission in the F body cars (Camaro/Firebird). The transmission was designed and manufactured by BorgWarner Automotive and was an evolution of the earlier T5 design. Larger and capable of handling more torque and horsepower, this trans became an instant hit with performance enthusiasts, race teams and hot rodders. This transmission was equipped with the following ratios:

- 1st gear – 2.97-1

- 2nd gear – 2.07-1

- 3rd gear – 1.43-1

- 4th gear – 1.00-1

- 5th gear – 0.80-1 (overdrive)

- 6th gear – 0.62-1 (overdrive)

- Reverse – 3.28-1

This unit is equipped with die-cast aluminum housings, a single-rail shift system, tapered roller bearings on all shafts, double-cone synchronizers and a constant-mesh synchronized reverse. The T56 easily handles 450 lbs.-ft. of torque and high-horsepower applications. The secret to keeping the transmission alive in high-horsepower situations is to make sure there is a high-enough differential ratio. This way the driver will get wheel spin instead of a twisted transmission. Chrysler also chose this transmission for the mighty Dodge Viper models, and it has lived well in this powerful sports car.

BorgWarner Automotive sold its manual-transmission line to Tremec, a state-of-the-art transmission manufacturer based in Mexico. This left BorgWarner more capacity and people to grow its transfer-case business, which is now the main core of its gearbox manufacturing. Tremec has continuously modified and improved the BorgWarner design in conjunction with the growing list of vehicle manufacturers using this transmission in high-end performance cars. In the 1998 model year GM began to use the more-powerful LS1 engine in the Camaro/Firebird line and the newly introduced C5 Corvette models, and Tremec redesigned the T56 with new ratios and a rear-mounted design for the C5 Corvette. The new ratios are:

- 1st gear – 2.66-1

- 2nd gear – 1 .78-1

- 3rd gear – 1.30-1

- 4th gear – 1.00-1

- 5th gear – 0.74-1 (overdrive)

- 6th gear – 0.50-1 (overdrive

- Reverse – 2.90-1

As usual, every new variation of the transmission required new refinements to perfect an already good design. When GM decided to mount the transmission directly to the differential in the C5 Corvette, providing much better weight distribution, it linked the clutch to the transmission though a torque tube. This design forced engineering changes to the T56 synchronizers, because of the change in inertia during the shifts. With no driveshaft to absorb some of the driveline inertia during the shift sequence, Tremec added triple-cone synchronizers to the 1st- and 2nd-gear synchronizer and double-cone synchronizers to the other forward speed gears. The 3rd-gear synchro ring was increased in diameter for greater holding power, and the synchro rings, which originally were paper lined, were changed to carbon-fiber material. On the F body cars the synchronizers remain the same in design, but the lining material was changed to carbon fiber.

Also introduced were two aftermarket units for the GM and Ford “muscle cars.” The aftermarket units were designed to be bolt-on replacements for the T5 transmission in older models. The input shaft on a T56 is 1⁄2 inch longer than a T5, and on the GM models Tremec produced an adapter plate that bolted to the front of the T56, which made up that difference. The Ford model came complete with its own bellhousing. These units are direct bolt-ons with modifications necessary to the cross member and exhaust systems, and a shortening of the driveshaft by 1.9 inches.

These aftermarket units became an instant hit with enthusiasts and hot-rodders. The double overdrive made it possible to run these cars with more-radical cams and maintain highway speeds without the valves climbing out of the engine. We have installed these units in everything from ’70s to late-model Impalas equipped with twin turbos, with great results.

The next designs introduced by Tremec were for the Aston Martin luxury grand touring models. These are equipped with paddle-type shifters mounted on the steering wheel as in the Formula 1 race cars. The extension housing is modified to use a series of solenoids to shift the unit electrically.

The next designs introduced by Tremec were two new models designed to fit the 4.6-liter Ford modular engines in the later Mustang models. The difference between the two units is in the speedometer drive. One has a gear-driven speedometer, and the other uses an electronic unit. Ford now is using the T56 to replace the anemic T45 on the Mustang Cobra.

GM, in the never-ending quest for market share, developed the Z06 model for the C5 Corvette, and this brought another design change for the T56 Corvette models. The Z06 ratios are:

- 1st gear – 2.97-1

- 2nd gear – 2.07-1

- 3rd gear – 1.43-1

- 4th gear – 1.00-1

- 5th gear – 0.84-1

- 6th gear – 0.56-1

- Reverse – 2.90-1

The main reason for the ratio changes was to get the Z06 model’s 0- to 60-mph times down for bragging rights. The two units are interchangeable as complete assemblies in any C5 Corvette, and we have many requests for these changes. Most of the World Challenge Teams and the Grand-Am cup series endurance teams interchange these units depending on track configuration. The Corvette geartrain is not interchangeable with F body units. The Z06 units use carbon-fiber synchro rings as in the LS1 Corvette units.

A new problem arose with the Viper units: breakage failure of the 3-4 shift fork. The fork is the same as in the F body and C5 Corvette models, and the original was made of aluminum. Tremec designed a new fork made of steel, which has solved that problem. The fork, part number TNEC0843, should be used to replace the 3-4 forks on any T56 rebuild. Although GM did not have a breakage problem with the 3-4 fork, we have seen many wear problems. The aluminum fork would wear at the point where the steel Z bracket retains it to the shift rail. Enough wear to just feel with your fingernail will cause these units to hop out of 3rd or 4th, so we replace every fork with steel, with excellent results.

The T56 is a strong, excellent-shifting unit that enables the average shop to upgrade customers’ cars and create new profits. Through our experience with hundreds of units we rebuild for race teams worldwide, this is a dependable, well-designed, smooth-shifting unit that offers tremendous potential for anyone to upgrade a vehicle to the latest and greatest or to create a hot rod or kit car.