Up to Standards

- Subject: Diagnosing transfer-case problems

- Units: NV 119, 126, 129, 136, 149, 226, 229, 236, 245, 246, 247, 249; BorgWarner 4404, 4405, 4406, 4410, 4411, 4472, 4473

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear Contributing Editor

The leading cause of stress in human beings is the unknown. There is nothing that causes more stress, anxiety and discomfort to us as a species. The key to all good horror stories is the writer’s ability to keep us in suspense by maintaining the reader in a long-term ignorance.

As a society we are almost universally afraid or tentative in the dark. All problems become magnified at night. This is because we receive most of our sensory information through our vision and rely much less on hearing, smell and touch. Remove the input our brain receives through our eyes and our minds begin to search for answers in the great unknown.

What has really changed in your home between sunset and sunrise? Nothing but the absence of light and, therefore, vision. Yet any noises that occur in the dark usually trigger an alarm response in our bodies. Noises that go “bump in the night” almost always turn out to be nothing when light restores our visual perception. Without that light, the unknown begins to elevate our stress level.

On the other hand, night can be your best friend if you have been trained to see it as such. Those of us who have been unfortunate enough to be involved in combat situations learned that in many instances the night can be your best friend. One man being pursued by many has a limited chance of survival in daylight. At night, if the solo quarry can break line of sight with his pursuers, he can immediately turn the situation around so that the hunter can easily become the hunted.

This follows through in our industry, where we must continually increase our education to understand how the machines we are trying to repair function. Judging from the number of tech calls and cries for help that we handle every day, the unknown is at crisis levels in our industry. This raises stress levels and creates frustration and anger in shops across the country and produces no valuable results.

Replacing parts is the last step in the repair process. The first step should be a methodical diagnosis to isolate the cause of the malfunction. This is not possible unless you understand how the component you are working on is supposed to operate and how it is related to the other systems that make up the modern motor vehicle.

One of the most-misunderstood areas we deal with is the late-model transfer case. We get a minimum of 10 calls a day from people who are either ignorant or confused about the operation of the transfer cases they are trying to repair. The transfer case has gone from a simple power divider to a complex unit that is in series with various systems such as ABS, traction control, stability control and other vehicle-management systems.

What we will discuss here is the theory of operation of the different types of transfer cases to let some light shine in and get rid of the unknown. In the beginning the transfer case was designed as a way to provide driving force to both vehicle axles for increased traction. This was done through chain- or gear-driven components that split torque from the transmission to the front and rear differentials 50/50. Shifts were made manually by a shift lever, and the transfer case had 2WD, 4W High, neutral and 4W Low.

The next step was to disconnect the front differential from the front axles in 2WD to save fuel and wear and tear on the differential and front output shaft. This was done initially by locking hubs on the front axle. This meant that when the driver wished to engage 4WD, he would have to exit the vehicle, lock the front hubs and then manually shift the transfer case into the desired mode of operation.

The hubs then graduated to automatic locking hubs, or an electrically or vacuum-operated front-axle disconnect so that getting out of the car was no longer necessary. As the market share for four-wheel-drive or all-wheel-drive vehicles increased, these systems became more sophisticated as the expense of the vehicles grew and the mindset of the owners changed. Our society went from radio to television and now has arrived at a point where people never have to get off the couch all evening to change channels because of remotes. The vehicle manufacturers were quick to note that no one wanted to get out of the vehicle to achieve 4WD and that even shifting a lever to engage the transfer case was annoying in vehicles costing $25,000 to $100,000.

Electronically controlled transfer cases and all-wheel-drive transfer cases became commonplace. These units use an internal viscous coupling with a mechanical differential, or a clutch pack hydraulically or electronically applied within the transfer case, to achieve 4WD.

The next issue was to make the vehicles safer. In an effort to save customers from themselves, the manufacturers developed ABS, traction control and stability control, as they were losing 50,000 customers a year in accidents. Obviously, having traction to four wheels in certain weather conditions creates a safer environment for the driver. To do this as needed without driver input required highly sophisticated computer control systems. Now we have vehicles that as the driver enters a turn will compare road speed with individual wheel speeds, compare steering angle with yaw rate and adjust braking or engine speed to keep the vehicle on the desired path with a minimum of understeer and oversteer. What this means to us as a profession is that now you really have to understand how these systems interact and how they function before you can repair one successfully.

The simple manually shifted transfer case is still on the road today in large numbers. The driver engages 4WD manually, and power is split 50/50 between the front and rear axles. What is commonly misunderstood is when these systems can be used. There is NEVER a time when you can successfully use 4WD on hard pavement unless snow or ice is present. This means that you cannot drive a vehicle with a manual transfer case in 4WD on hard pavement in the rain without causing problems. The reason for this is that the wheels turn at different speeds in even gentle turns. This causes the driveline to “wind up,” locking up transfer-case components because the tires cannot slip. In snow, ice, gravel, sand or other loose material the wheels can slip so that the differences in speed do not stress the transfer-case chain and geartrain.

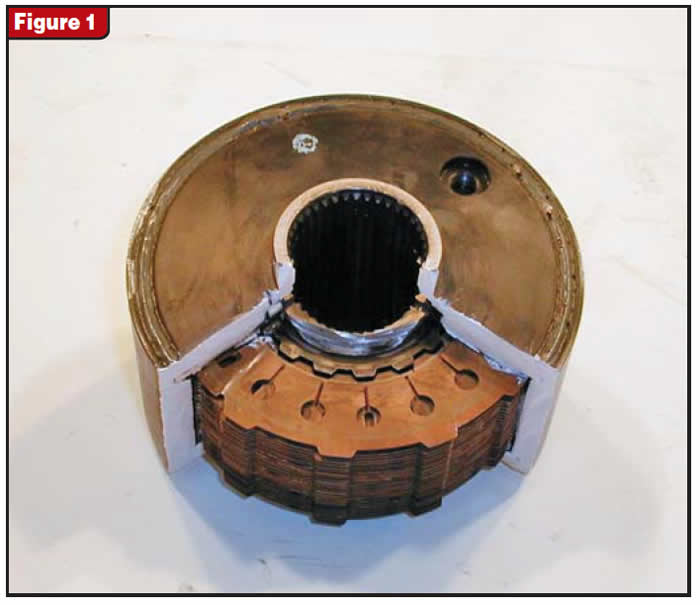

Now we come to the viscous coupling, which you see in cutaway form in figures 1 and 2. The viscous coupling, in a sealed case, has alternately splined metal discs. One set is splined internally to the output shaft and the other is splined to the case of the coupling, which is attached through another set of splines to an open differential and/or the drive sprocket of the chain drive.

Although these discs appear similar to those in automatic-transmission clutch packs, they are never in contact with each other. The case of the viscous coupling is partially filled with a silicone fluid that has some interesting qualities. The viscosity of this fluid increases almost instantly with heat, causing it to expand and fill the entire case. The discs now are forced to run through this fluid and become coupled by the force necessary to “shear” through this sticky fluid. This transfers power to the front axle, splitting torque between the rear and the front and making both axles transmit power to the wheels. When the slippage at the rear axle is eliminated by equalization of shaft speeds, the fluid cools and recedes, allowing power to flow to only the rear axle until the next slippage occurs.

The viscous-coupling design for transfer cases was an advance, but the coupling was a reactive device that had to wait for a slip to occur before becoming active. Viscous couplings are not new and are found in many components. Manual fan clutches on automotive cooling systems have viscous couplings, as do some torque converters and differentials, and some vehicles have a center viscous coupling in the driveline.

There is nothing you can do as a shop to repair a viscous coupling. When they are bad they must be replaced. How do they go bad when no driver control is present? The main cause is tires. If a vehicle’s tires are not all within 1/4 inch in circumference, the viscous coupling interprets the difference in the rolling ratio as a slip and begins to send power to the front axle. After a short time of working constantly, the viscous coupling overheats and fails. If you replace a viscous coupling without measuring tire circumference, it may fail within several weeks. The end result is that you pay for a new coupling that also will fail if the tire-size issue is not cured.

Looking at the size on the tire sidewalls is not enough, as that size means nothing when the tire is inflated. You must measure each tire with a stagger gauge or a tape measure or else pay the price. You will be surprised at how many problems you will no longer have to deal with once you make a habit of measuring all four tires on every vehicle you work on. Remember that mismatched tire sizes also will kill differentials in front-wheel-drive automatic transmissions.

We get many questions as to whether changing the transfer-case fluid will help a viscous coupling perform better. The answer is no, because the viscous coupling is a sealed unit and the fluid in the transfer case serves only as a lubricant. Units that use a viscous coupling are the NV 119, 129, 149, 229 and 249 and the BorgWarner 4404, 4410, 4472 and 4473.

The next advance in transfer-case technology came with “automatic” or “active” transfer cases. These are clutch-driven transfer cases in which a clutch pack in the transfer case is engaged to send torque to the front axle. With the exception of the New Venture 247 transfer case, these are all computer-controlled units that have the ability to “sense” or detect a slip before it happens. Understanding how this works should make it crystal clear how sensitive these units are to mismatched tire sizes.

Ford says in its repair manuals that a difference of 0.006 inch in tire size can set a code. On the GM side, a 15-rpm difference in prop-shaft speeds can set a code. A 15-rpm difference in prop-shaft speeds correlates to a difference of 1/16 inch in tread wear. Measure the tires before you do anything else on these transfer cases. A safe bet is usually to have all four tires within 1/4 inch.

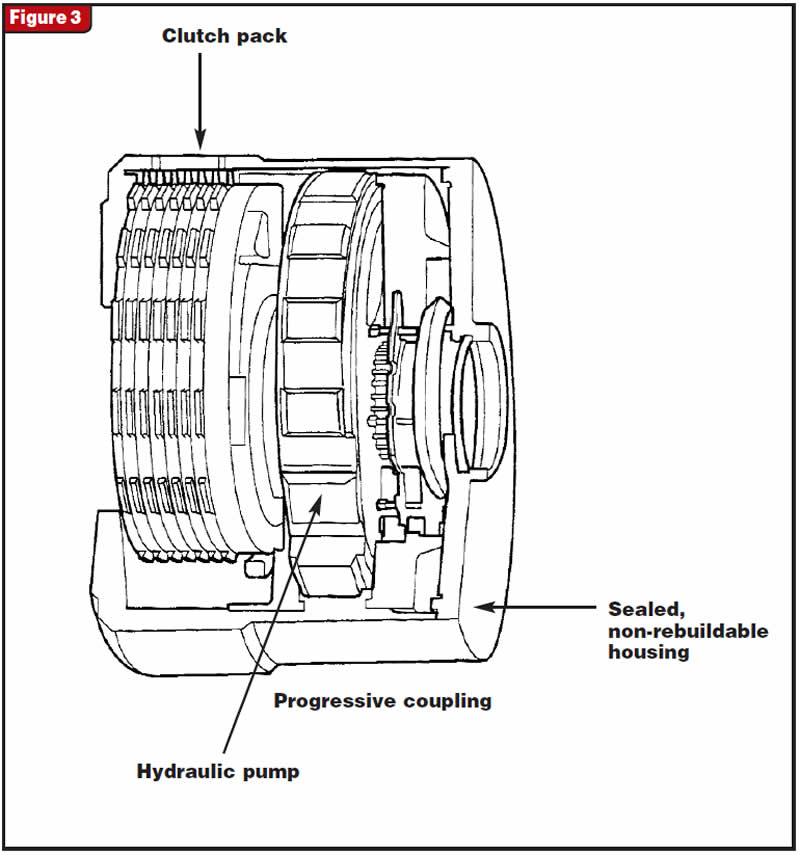

Now, back to the NV 247, which is used in Jeeps. Instead of a viscous coupling this unit, shown in Figure 3, has a “progressive pump coupling” that is a sealed, non-rebuildable component. In the 247 there are two pumps. The first is a gerotor type of pump that is driven off the output shaft and provides pressurized lube oil throughout the transfer case and provides oil to the pump coupler. The pump coupler contains a second pump, with sophisticated valving, to apply a clutch pack that is also inside the coupling. This unit works just like a viscous coupling in that a difference in shaft speeds causes the pump to pressurize the clutches, sending power to the front axle until shaft speeds equalize and the pump loses pressure. These units are extremely sensitive to fluid quality. They also are reactive units, in that nothing happens until there is a slip.

The other automatic or active transfer cases that feature complete computer controls are the NV 126, 136, 226, 236, 245 and 246, and the BorgWarner 4405, 4406 and 4411. All these units are capable of electronically anticipating a slip and sending power through the clutch pack to the front axle. This is done through a comparison of vehicle road speed with prop-shaft speeds, and the computer changes the duty cycle on the clutch apply to eliminate any differences in speed.

Tied into these systems is throttle position, so that in the automatic position under hard acceleration the unit goes from 2WD to 4WD within milliseconds. The computer will monitor the ABS, traction control, transmission manual-lever position, brake switches and stability control. This means that you need to scan all applicable systems to diagnose a problem. You must check for codes in the powertrain, drivetrain, ABS, body and chassis systems.

Ford has further complications with its multiplex wiring systems. Because of the combination of signal paths running through the same circuits, problems such as a bad rear-glass heater grid, a shorted door-ajar signal or a shorted windshield wiper can cause a transfer case to malfunction.

If you examine the manuals involved in repairing active transfer cases you immediately realize how things have changed. There are 40-50 pages on the actual unit repair and 200 pages of diagnostic codes, circuits and troubleshooting trees. The stability-control systems on late-model vehicles are capable of comparing steering angle, yaw rate, road speed and throttle opening with specifications in the computer database. Using these inputs, it can anticipate a driver entering a turn at too high a speed and activate the transfer case to prevent the vehicle from understeering or oversteering. Certain automatic transmissions have the same capability to prevent unnecessary upshifts when the vehicle is cornering.

It is a brave new world out there. You can look at it as a negative complicating your life, or you can view it as a plus making the knowledgeable technician a valuable commodity. The more you know and understand, the lower your stress level will be and the more satisfaction you will have with your work.