Up to Standards

- Subject: Four-wheel-drive disconnect systems

- Units: BorgWarner, New Venture transfer cases

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The motor vehicle is a combination of many separate components and operating systems that are mechanical, hydraulic, electronic, and air or vacuum operated. Successful diagnosis and repair can be accomplished only by viewing the problem with a systemic approach and careful consideration of the entire group of components that can influence or be the cause of the complaint.

It is relatively easy in our work environment to get lost by concentrating on a major assembly such as a differential or transfer case without examining all the systems that are interconnected and must function properly to have a correct outcome. Simple issues, if disregarded or skipped, can waste precious time and lead you into a comedy of errors. For instance, if you did not check for proper battery voltage before running a computer scan, you may fool yourself into a long afternoon. If you have a transfer case or differential problem to sort out and you do anything before measuring the vehicle tire sizes with a stagger gauge, you’ve just dealt yourself a losing hand.

Ancillary parts that complete an operation are often overlooked in the haste to get to the bigger components involved, and in this article we examine 4WD disconnect systems and the effects they have on the 4WD operation. The front differential of a 4WD vehicle is driven by the front output shaft of the transfer case. Many models are equipped with a disconnect system so that the front differential can freewheel in 2WD mode, which reduces parasitic drag from unused components, saving fuel and horsepower, and wear and tear on the components involved.

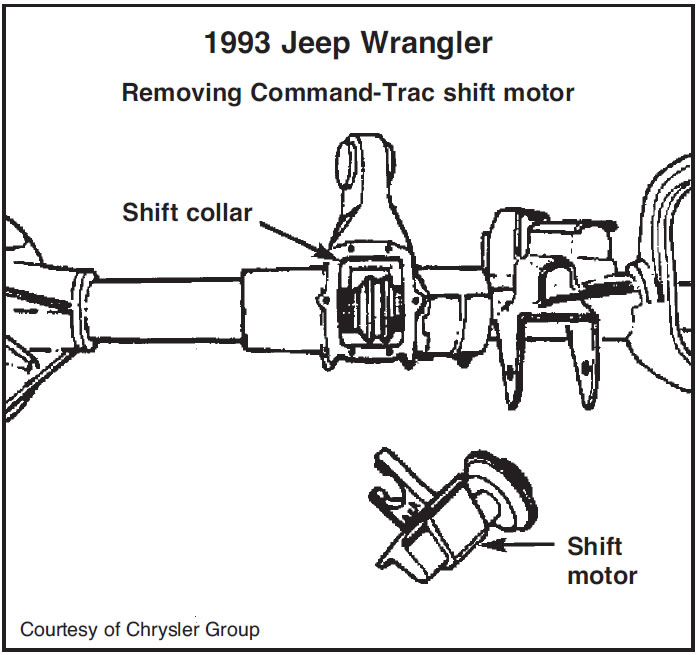

The typical disconnect “box” or system usually involves taking the longer of the two front axles and splitting it into two shafts, with a disconnect using a sliding sleeve splined to one half and a shifting fork to move the sleeve to lock the two parts of the axle together when 4WD mode is engaged. Systems are cable or vacuum operated or electronic, depending on the model.

As simple as these systems are, they result in a bunch of technical calls regarding what is assumed to be a transfer-case problem but turns out to be farther down the line. In the evolution of transfer-case technology, we started with big, heavy transfer cases that relied upon locking hubs to permit the front wheels to free wheel in 2WD. This went away as the SUV craze took off, as the drivers who were new to 4WD did not wish to get out of the vehicle to lock or unlock hubs.

The various types of disconnects evolved as active or intelligent transfer cases evolved. Oddly enough, even though fuel economy is a paramount concern in buyers’ minds, several manufacturers have stopped engineering disconnect designs into their products. It may be a move to cut costs or simplify systems to reduce claims under longer warranties, but it puts much more strain on the components. If there is no disconnect system, the front output shaft of the transfer case is always turning. This means that the chain or gear set is always turning the sprockets, resulting in shorter component life.

You can see the difference between similar models of a unit such as the NV271/273. Ford trucks are equipped with a disconnect system and enjoy a low failure rate; Dodge vehicles equipped with the same transfer case suffer catastrophic failures because the heavy chain in those units is always turning.

A quick and simple description of various disconnect systems:

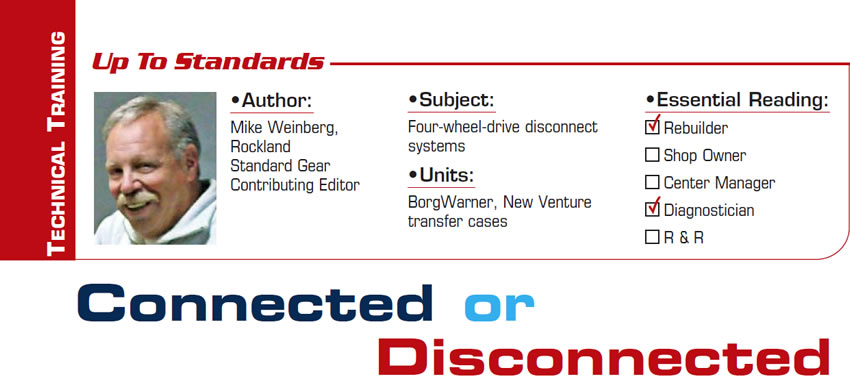

1987-94 Jeeps, 1987-98 Dodge

- 4-hose vacuum switch on transfer case

- 1 – Hose to manifold vacuum

- 2 – Hose to 2WD side of front axle servo motor

- 3 – Hose to 4WD side of front axle servo motor

- 4 – Hose to vent to open air

- 5 – Note: On Jeep YJ models, the hose to the 4WD vacuum servo also operates a 4WD dashboard light.

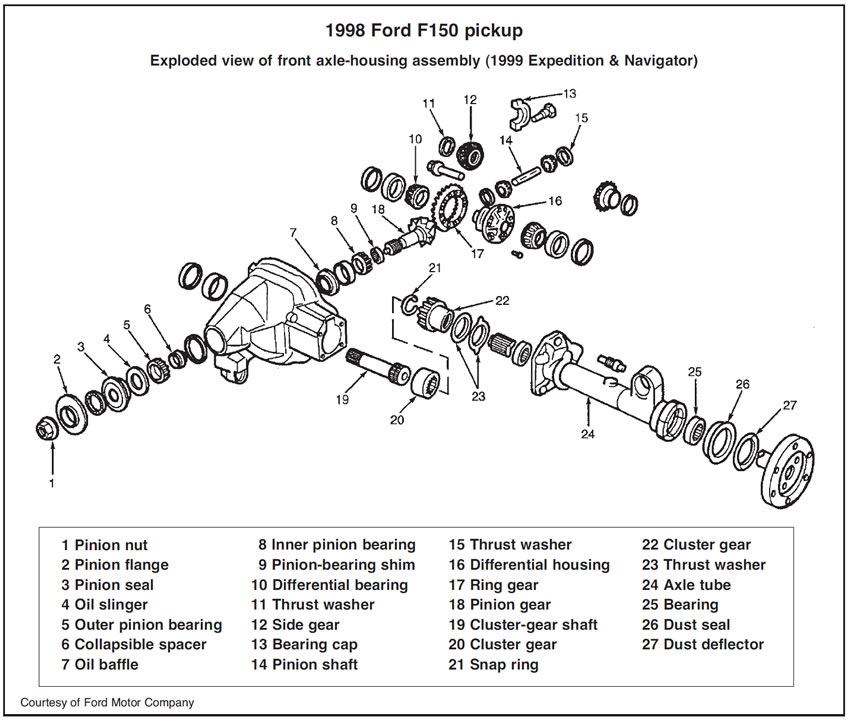

1983-present GM S10 trucks with NV231/236 transfer case

- 3-hose vacuum switch on transfer case

- 1 – One hose to manifold vacuum

- 2 – One hose to 4WD side of front-axle servo motor

- 3 – One hose to vent to open air

1995-up Ford electric-over-vacuum axle disconnect

- Control from module to vacuum switch

- 1-2WD no electric to switch

- 2-4WD or Auto 4WD Electric to switch vacuum to operate axle disconnect

2,000-up Ford pickups

- Electric-over-vacuum wheel hubs disconnect

- Module controlled to vacuum switch

- 1 – 2WD no electric circuit to switch

- 2 – 4WD or auto electric module switches vacuum to outer wheel hubs, which have springs to return to 2WD when vacuum is switched off.

GM electronic disconnect, full-size vehicles

- 1987-1994 2 wire system

- 1 – 2WD, no electric circuit to switch

- 2 – 4WD, electric circuit completed to switch

- Late 1994-present, 4-wire system

- 1 – voltage from transfer-case switch or module

- 2 – 12-volt circuit to ignition on

- 3 – Ground wire

- 4 – Circuit to computer

- 5 – 2WD, no voltage to servo

- 5 – 4WD, voltage to servo

2002-present Chevy Trailblazer, GMC Envoy

- 2-wire system: 1 wire, voltage from transfer-case switch; 1 wire to ground

- 1 – 2WD no voltage to switch

- 2 – 4WD voltage to switch

This system has a high failure rate. It is a separate bolt-on box to the 7.5-inch independent-front-suspension axle, since there is no lube fill and the assembly is pre-greased at the factory. GM has discontinued sales of the complete disconnect box and offers service parts only. We manufacture and sell this part from new OEM materials, as the collective parts to rebuild it cost more than the entire assembly.

One should be aware of the difference between all-wheel-drive and four-wheel-drive units, as AWD units have no disconnect supplied. Here is a quick-reference guide to simplify diagnosis for select units.

GM:

- All transfer cases had disconnect system except for these AWD units: NV126C, 136C, 149C; BW 4472C and 4473C

Jeep:

- All transfer cases had a disconnect system from 1983 to ’95 except for 1987-up NV249J and 242J.

Dodge:

- All 1987-2001 transfer cases had disconnect, except for 242D; after 2001 no disconnect systems supplied.

Ford:

- BW4405F 1995-96 – disconnect

- BW4405F 1997 up – no disconnect

- BW4411F all years – no disconnect

- BW4410F, BW4412F, BW4414F – no disconnect, AWD

- BW4406F torque on demand (TOD) 1997-98 – disconnect

- BW4406F TOD 1999 up – no disconnect

- BW4406F electronic or manual – no disconnect

- BW4416F – disconnect

- BW1354F 1988-98 – disconnect

- BW1354F 1999 up – no disconnect

- NV271/273 all years – disconnect

- BW4404F – no disconnect, AWD

- BW4410F – no disconnect, AWD

- BW4414F – no disconnect, AWD

Whenever a transfer-case diagnostic issue comes into the shop, be sure to examine all parts of the system before doing major surgery on the vehicle. It will present a money-making opportunity, and value added for your customer, if you explain and suggest that any 4WD vehicle without an axle-disconnect system, and all AWD transfer cases, should be serviced more frequently because of component stress induced by continuous operation of the front driveshaft into the transfer case.