Tires: What You Don’t Know Can Hurt You

- Author: Mike Weinberg, Contributing Editor

The cliché “What you don’t know can’t hurt you” is way out of date. The single most-important commodity in the world we operate in is knowledge. Information – and that means good, factual information – is the only thing that stands between us and expensive failures. Our quest for information will include a good working knowledge of the operation of the complex systems that comprise the modern motor vehicle and their relation to one another, feedback from the customer to fully understand their problem and the results they want you to achieve, and a thorough and complete observation of the vehicle you are working on.

One of the easiest mistakes we can make in business is to lose sight of the big picture and focus only on that part of the car that we believe is our concern, such as the transmission or transfer case. There is probably no one in our industry who hasn’t wasted a bunch of time trying to figure out a diagnostic problem because they did not completely examine the entire vehicle. There are no shortcuts, and any assumptions you make will wind up making you sorry at some point.

A prime and common example of this is a technician who undertakes an electrical diagnosis of a computer-related problem without first checking battery voltage. That simple error can drive you to drink, because an undercharged battery will lead you down many wrong paths. I have mentioned countless times that you should work on a vehicle “from the outside in.” This means that it is necessary to eliminate all simple issues on the vehicle before getting into the big labor-intensive work.

Since the car is a complex collection of interrelated systems, it does not pay to begin removing a major component without first checking and validating all external factors that can affect that component. A friend of mine who oversees one of the major vehicle-manufacturer transmission-rebuild programs claims that more than 50% of the units returned as cores don’t have enough wrong with them to warrant a replacement and that the shops did not diagnose the vehicles properly before ordering units. We all know that replacing parts without locating the cause of the failure is the beginning of a new comeback or a “never leave.”

Among the most-overlooked vehicle parts are the tires. Late-model cars commonly are equipped with ABS, traction control, stability control, computer-actuated four-wheel-drive and all-wheel-drive systems, and complex computer-controlled transmissions. Since all these systems are interrelated through a number of powertrain, drivetrain and body computers, anything that affects one of these systems will affect all of them. This can result in a lot of wasted diagnostic time because of overlooking simple external factors.

If the vehicle’s tires are worn, improperly inflated or mismatched in sizes, every system that relates to wheel speed will be getting improper information. This results in problems with ABS, stability control and traction control and creates an environment in which computer-controlled transmissions and transfer cases begin to set trouble codes and start to fail.

One of the first things you need to do at the beginning of any problem-solving vehicle inspection is to make sure all four tires are the same size in actual dimension (measured, not from the sidewall labels), are of equal and correct pressures at all four corners, and that all tire circumferences are within 1⁄4 inch. If you make this routine a habit, I will bet you a good dinner at a place of your choice that the 10 minutes you spend on a thorough tire check will save you hundreds of hours of wasted diagnostic time each year.

Since many of the calls received on our tech line result from tire problems, I have done some research on tires and found that there was a lot I didn’t know about the modern tires we take for granted. As a longtime professional race driver I always thought that I had a good understanding of tire technology, but the technology in the production of these black doughnuts has grown at the same rate as other parts of the car.

Perhaps the biggest factor in the handling and stopping power of the late-model vehicles has been the tremendous improvement in tires. The following will help you increase your knowledge and understanding of the information provided on the tire sidewall and how it relates to the proper operation of the vehicle, your customer’s safety and the insurance that the tires are supposed to be on this model of the car or truck.

Remember that after the customer takes possession of the car from the dealer or a previous owner, many changes can take place. Whether because of economic reasons (lack of funds), or the American desire for individuality (plenty of money to spend on tires and wheels), many vehicles you will work on will not be equipped with original tires and wheels. By understanding which tires should be on the vehicle and which ones are, you can save yourself some headaches.

Example: A young guy likes the “low-rider” style of vehicle. You can chuck a bunch of money into lowering a vehicle by correctly modifying the suspension and springs, installing dropped spindles etc. Now, our boy has champagne taste and beer pockets, so he simply trades off the current wheel and tire specified for his vehicle for a set of 13-inch wheels and tires, and like magic he has a “low-rider” to impress the local females. He has gone from P235/75R15 to P185/80R13 tires. The 15-inch tires had a load rating of 2,035 lbs. at 35 psi, and the 13-inchers have nowhere near that capacity.

The problems begin with the wheel bearings and wind up with every speed-related information system on the car being out of whack. This is a Kamikaze waiting for a place to land, but this is the real world.

The first step in understanding tires is to know what the terminology means.

Overall diameter – Outside diameter of a tire mounted on the wheel at the correct air pressure but not on the ground under load from the vehicle weight

Section width (overall width) – The maximum width of a mounted, properly inflated tire that is not under load

Free radius – A measure of a mounted, inflated tire under load on the vehicle. The measurement is from the axle centerline to the top of the tire nearest the vehicle body.

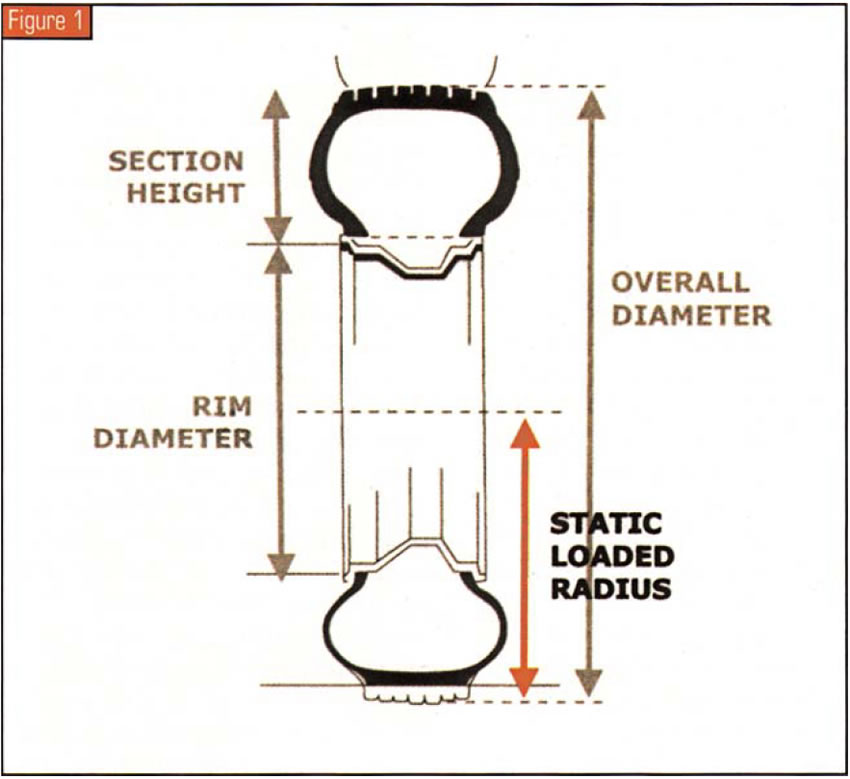

Loaded radius (see Figure 1) – A measure from the axle centerline to the ground (90° angle) when the tire is mounted on the vehicle under load (this will be different from free radius because of tire deflection from vehicle weight.)

Nominal wheel diameter – The measurement from bead to bead of a mounted inflated tire; the inside diameter of the mounted tire

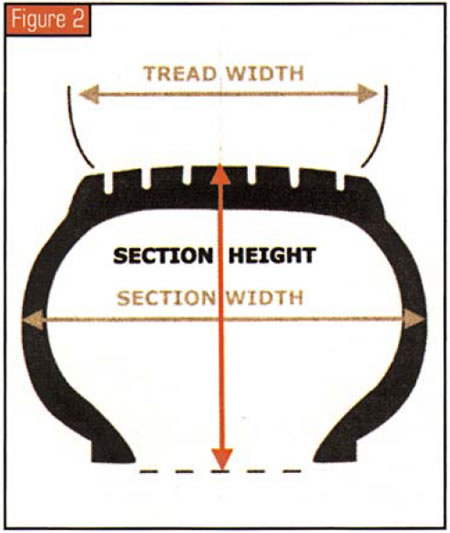

Section height – Measurement from the tread face to the tire bead (see Figure 2)

Loaded section height – The measurement of the loaded radius subtracting one half of the nominal rim diameter.

Tread width – The measurement of the tread from shoulder to shoulder. Tread width is always less than section width (see Figure 2).

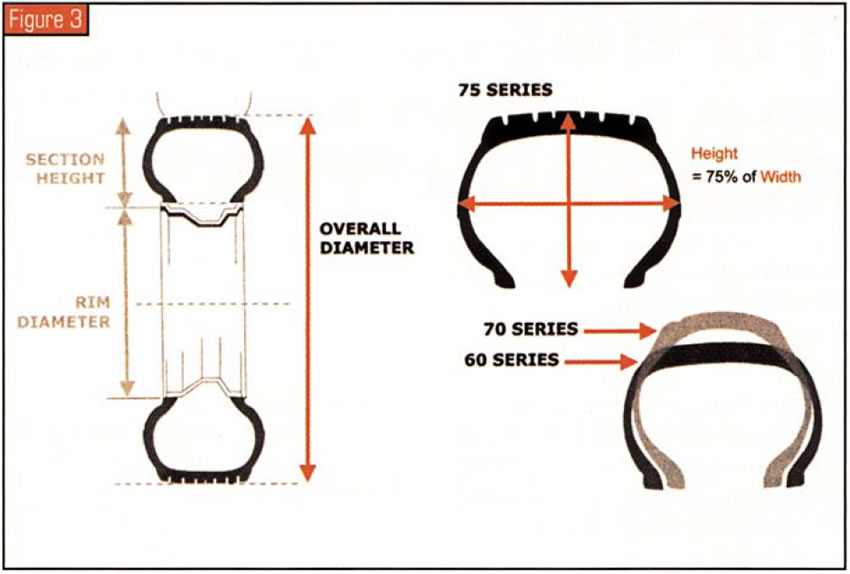

Aspect ratio – Tire section height expressed as a percentage of section width and appearing on the tire sidewall label as a series number. On a 60-series tire, the sidewall height is 60% of the section width (see Figure 3).

A 50-series tire’s sidewall is 50% as tall as the section width, and the sidewall of a 35-series tire is 35% as tall as the section width; to put this into a formula, aspect ratio = section height ÷ section width x 100. For example, a tire with a section height of 3 inches has a section width of 10 inches. Dividing 3 by 10 and multiplying the result by 100 gives you an aspect ratio of 30. You will hear about “low-aspect-ratio” tires, which are used to gain handling performance by having a lower, less-flexible sidewall. Usually, tires with a lower aspect ratio will give a harder ride from a comfort standpoint, as the driver will feel road imperfections more. Changing the aspect ratio will cause a dramatic change in vehicle handling.

It is important to be able to understand the large amount of information on the tire sidewall. If you know what all the numbers mean, and the significance of the various ratings, you will be on your way to eliminating tires as a source of transmission, transfer-case, ABS and traction-control problems. The sidewall will tell you the size, tread-wear rating, traction rating, maximum inflation pressures, speed rating, rotational direction, serial number, manufacturing site and other information.

There are three sizing systems that you will come across for passenger cars. P-Metric, the most-common system, identifies tire size using the cross section, aspect ratio, rim diameter and type of construction, with measurements in millimeters. Here is a breakdown of a typical size designation:

P235/50R16

- P=passenger car

- 235=section width in millimeters

- 50=aspect ratio

- R=radial construction

- 16=wheel diameter in inches.

On the P-Metric system, a speed rating also may be included after the aspect-ratio designation.

The next system is European metric, which is close to P-Metric but does not use the P for passenger-car designation.

The European metric also does not include an aspect-ratio code unless the ratio is under 82. A typical breakdown for this system is:

185/70SR14

- 185=section width in millimeters

- 70=aspect ratio

- S=speed rating

- R=radial construction

- 14=rim size in inches (Note: Some European metric designations state rim size in millimeters.)

The last system for passenger cars is the old alpha-numeric system that started in the 1960s. Many of these sizes are still in demand today with hotrods, classic cars and restoration muscle cars. The key to this code follows:

BR60-13

- B=Load rating, which can run from A through N. The higher the letter, the greater the load rating

- R=Radial construction

- 60=aspect ratio

- 13=rim size.

Note – as these alpha-numeric sizes may not be available any longer, the customer must go to a P-metric size that will match the overall diameter, aspect ratio and section width. It is critical to your well-being to make sure that the tire sizes are as close as possible to the original size to prevent speedometer errors, ABS and traction-control problems, and changes in the final-drive ratio that can cause changes in engine speed and torque curve, which will influence the ECM. The effect of this can be generation of the same codes as in a front-wheel-drive automatic with incorrect chain-sprocket ratios.

When a customer wants to change wheel sizes to give his vehicle a “hotter” appearance, it is important to note that this will require a change in tire size to keep the overall diameter of the tire the same as with original rims. This is done by plus-sizing, which adds one inch per plus-size code. Plus 1 indicates a one-inch increase in wheel size, plus 2 adds 2 inches etc. The correct way to do this is to provide a tire that uses a lower aspect ratio and a greater section width and tread width while maintaining the same overall diameter as stock to prevent the problems mentioned in the previous paragraph related to increasing overall diameter.

Now that we have a grasp on passenger cars, it is time to look at light-truck tires, which also have three ID systems.

Light-truck metric is similar to P-metric:

LT235/75R15C

- LT=light-truck applications

- 235=section width in millimeters

- 75=aspect ratio

- R=radial construction

- 15=rim diameter

- C=load rating.

Tires that carry the LT designation are designed for use on vehicles that carry heavier loads and are tow capable, which includes pickups, vans and SUVs. Be careful if you come across a truck-designed vehicle that is running P tires.

Light-truck high-flotation tires are created with lower aspect ratios to operate with better traction in off-road conditions such as sand, soft dirt and gravel. They also have specific identifiers:

31X10.5R15 LT/C

- 31=overall tire diameter of 31 inches

- 10.5=section width of 10.5 inches

- R=radial construction

- 15=rim diameter

- C=load range

Light truck numeric is an older system developed for commercial vehicles:

7.50R16LT/D

- 7.50=section width of 7.5 inches

- R=radial construction

- 16=rim diameter

- LT=light truck

- D=load range

Note: You will run across tires that have an ST identifier. ST stands for special trailer tires. This rubber has no place on any motor vehicle and should be used only on trailers.

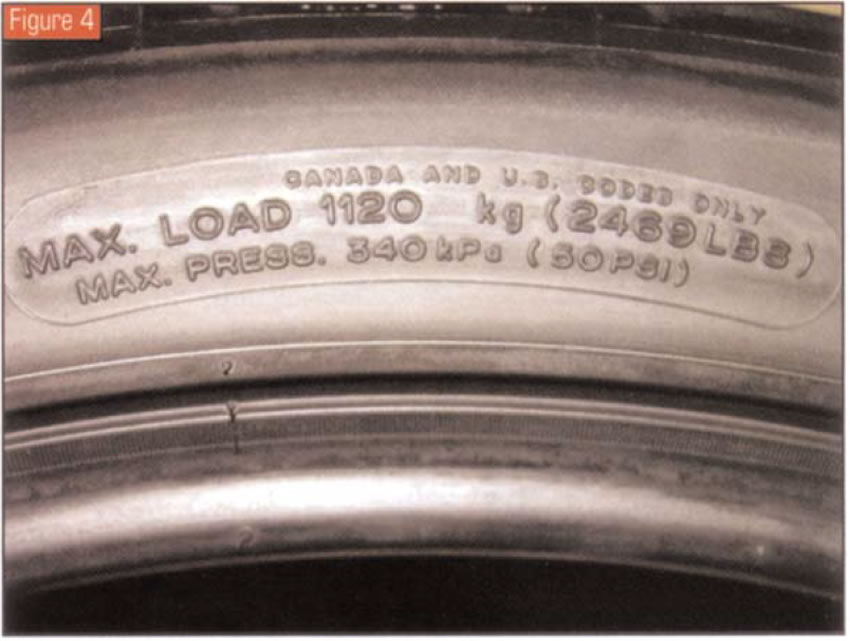

Load ratings are displayed on the vehicle sidewall as either a letter code or an actual weight in pounds or kilograms that represents the safe load on that corner of the vehicle (see Figure 4). To verify that the load rating is correct for the vehicle, multiply the load rating in pounds by 4 and compare the answer with the vehicle’s stated GVW (gross vehicle weight) rating. For example, with a tire set load-rated at 1,200 lbs., 1,200 x 4 =4,800 lbs.

This does not, however, account for the loads people routinely put in their cars and trucks. Most owners have no idea of GVW rating and are in the habit of filling up a truck with “as much as it will take.” It is always interesting when you take a test drive in a vehicle that is 2,000 lbs. overloaded and have to learn to increase your braking zone by 200 yards or watch the stop sign go on by.

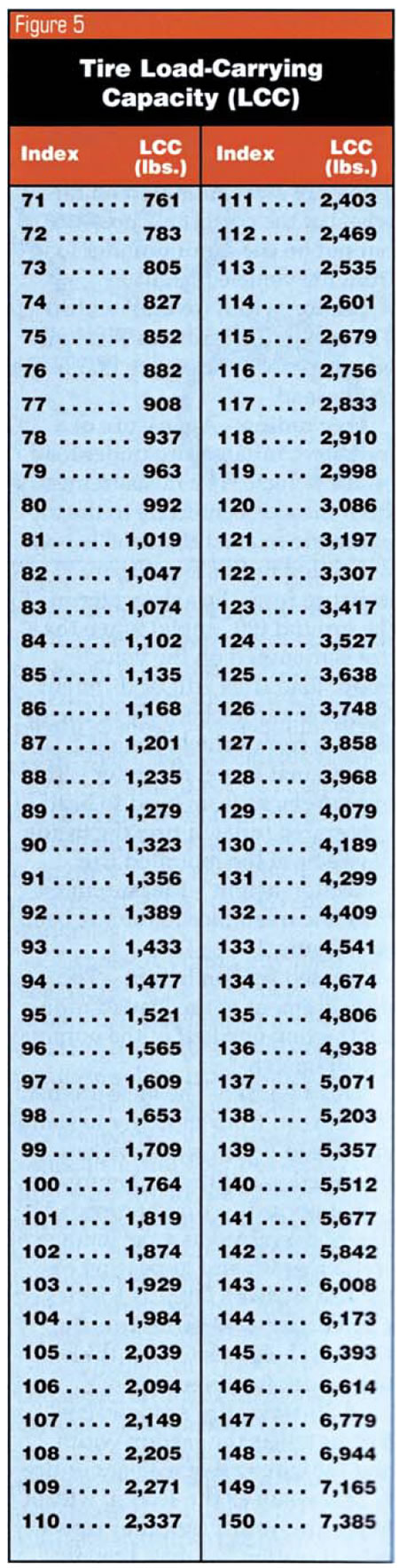

Alpha-numeric tires display a load rating from A to N. The more advanced the letter, the higher the load rating at the maximum allowable tire pressure. On P-metric tires, extra-load-rated tires are identified with XL. Understand that a tire may have a working-pressure indication of 35 psi as normal and 44 psi as maximum. Running the tire at the highest pressure does not increase its load capacity. Figure 5 matches the load-index number on some tires to the load-carrying capacity of the tire. The index begins at 71 and goes up to 150.

Speed rating is another issue that consumers often overlook in a quest to save money. Many late-model cars are capable of high speeds and require speed-rated tires. The sidewall is marked with speed ratings as well as other identifiers. Look at the following examples to understand the code:

P195/60R15 87S

- P=passenger car

- 195=section width of 195 millimeters

- 60=aspect ratio

- R=radial construction

- 15=rim diameter

- 87=load index of 1,201 lbs. (from chart)

- S=speed rating of 112 mph

285/35ZR19 99Y

This tire has a load rating of 99, which is 1,709 lbs., and the Y speed rating gives it a top speed of 186 mph. I know that there is no place outside of a race track where you can legally drive at the rated speeds. I also know that this is the real world, where people will try it out if it is there. You don’t want to be at 186 mph on tires rated for 112 mph. The heat and squirm of the tread and sidewalls will quickly cause the tire to fail, and none of these people will have the skill or experience to get out of the mess they will be in. We have a customer who sent us a video from an in-car camera of his Dodge Viper traveling through an Easy Pass type of toll booth in the Midwest at 206 mph at 3 a.m. You can’t make this stuff up.

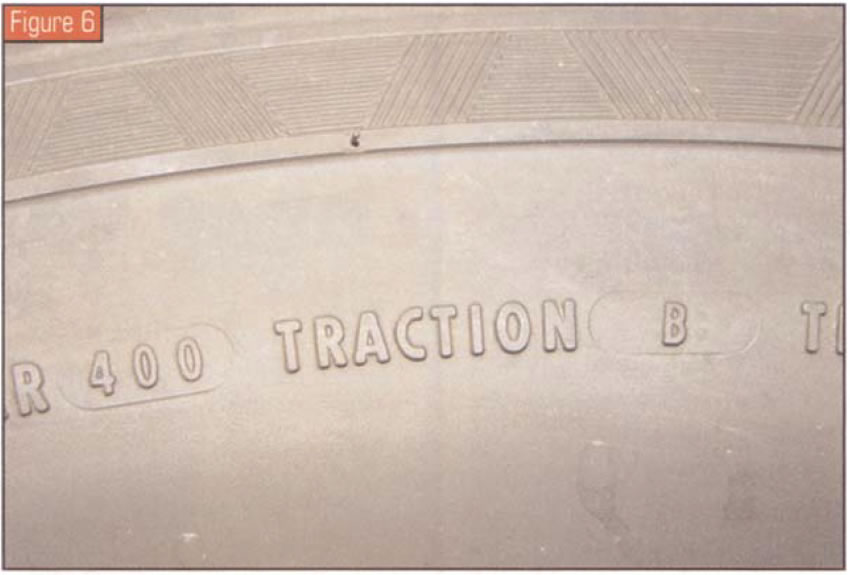

Traction grades now are included on many tire sidewalls. They are listed as A, B or C and provide an indication of the tire’s tested ability to handle braking in a straight line on wet-surface asphalt or concrete, with A being the highest (see Figure 6). This is an attempt to limit accidents caused by “aquaplaning” of the tires under wet conditions.

Aquaplaning is created by vehicle speed, tread depth, tread design, tread compound, tire width, water depth, vehicle weight and tire inflation. Under certain conditions, the tire actually will be riding on a wedge of water and have no actual contact with the road surface. This results in loss of steering control and the ability to brake. Much as a crankshaft rides on an oil wedge and does not touch the crank bearings, the same happens in wet weather on the highways.

One of the major problems you will find is that many tread designs have a specific rotational direction to exhaust water correctly through the tread grooves. The direction of rotation is molded into the sidewall of the tire (see Figure 7), but we have seen many do-it-yourselfers rotate their tires with no clue as to proper orientation.

The second major issue is tire inflation. Underinflated tires will allow the center of the tread to go concave and reduce the amount of traction dramatically. A side effect of these conditions is ABS, traction-control and transmission and transfer-case codes that will show up. If the customer doesn’t crash the vehicle, he may send you on a diagnostic adventure when all that is wrong is tire related.

Last but not least is the increasing trend to inflation sensors. Many luxury cars or sports cars that are not equipped with spare tires are equipped with inflation sensors, which are radio-frequency transmitters mounted inside the wheels, generally close to the tire valve. The units read internal tire pressure and send this data to one of the vehicle microprocessors, which signal the driver when a tire is not properly inflated.

The federal government, in its endless zeal to protect us from ourselves, is requiring that all cars and light trucks have tire-pressure monitoring systems by 2008. This is one more code-sensitive area, where some of these systems are wheel specific and will set codes if the tires are rotated. To get rid of this problem it is often necessary to reprogram the sensor and computer to learn its new location.

As you can see, tires are hardly to be taken for granted. They are one of the first things to add to your vehicle checklist before you start turning wrenches, and you will rid yourself of a lot of pesky code and operational problems.

Thanks to SEMA (Specialty Equipment Manufacturers Association), Modern Tire Dealer magazine and Bridgestone Tires for “The Performance Handbook 2005,” which gave me a major education on tire identification that I have tried to pass on to our readers.