Shift Pointers

- Subject: Detection of red glycol-based antifreeze in transmission fluid

- Essential Reading: Rebuilder, Shop Owner, Center Manager, Diagnostician

- Author: Robbie Ferguson

As you may know, many of the OEs have started using a red glycol-based antifreeze. Some of these cooling systems will use a ratio of 70% glycol, 30% water. The problem is that when the red glycol-based antifreeze is introduced into the transmission because of a failed aluminum cooler and/or radiator, it no longer causes the “strawberry milkshake” that we are all too familiar with. So let’s walk through a common scenario related to this glycol product:

You get a vehicle in the shop with common shifting concerns and/or a shudder – no different from any other day. You pull the unit out and find failed frictions. No big deal, right? No hard-part damage; it just needs clutches and reassembled. Since the manager/owner wants to save a nickel, he says: “We can run the original converter, right? The hub looks good, and the unit didn’t have any metal in it.”

Well, in this case it may seem to be a viable option.

The unit is installed and the original converter is re-used. Well, in no time the vehicle is back in the shop with a shudder complaint. So, the logical thought is that it must have needed a converter after all. The fluid looks good and still no metal, so as the R&R guy is mumbling things under his breath that we can’t very well mention in this article, he pulls it back out and installs another converter. The test drive is fine, and the vehicle is delivered back to the customer with an apology.

Somewhere between a week and a month later, the irate customer returns with the same shudder complaint. They now question your shop’s ability and the great references they received from their friends. They mention how much money they paid you to fix their vehicle and that you have not fixed anything. After you finally get the customer calmed down and have them drop off the vehicle, you hop in it and, sure enough, that same shudder has returned. Well, you get the pleasure of telling your R&R guy to “pull it back out.” This time he’s not mumbling; he’s letting everyone in the shop know what’s on his mind.

He gets the unit on the builder’s bench and, lo and behold, there is a problem with the frictions again. The first thought may be, “These worthless plates are junk.” At this point, there should be some questions and some extra investigation effort put into this vehicle that is in your shop for the third time.

The bottom line is that glycol anti-freeze may be present in the transmission fluid and has never been detected. Since the converter was not replaced the first time, and the source of the contamination was not located and eliminated, it re-contaminated the freshly built unit with glycol. Then the converter was replaced but the unit was still contaminated, and now you are back to square one. At this point you are stuck buying another banner kit, trying to warrant out the converter, and most likely replacing the radiator and/or external cooler. You should be able to get the customer to pay for the radiator and/or cooler, but are you going to charge them labor to replace it? Either way, your profit margin is up in smoke – or maybe steam in this case – and, even worse, you have an unhappy customer.

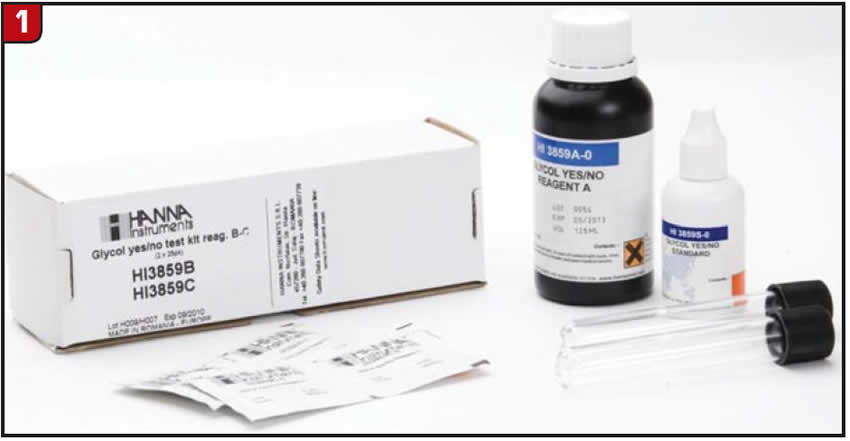

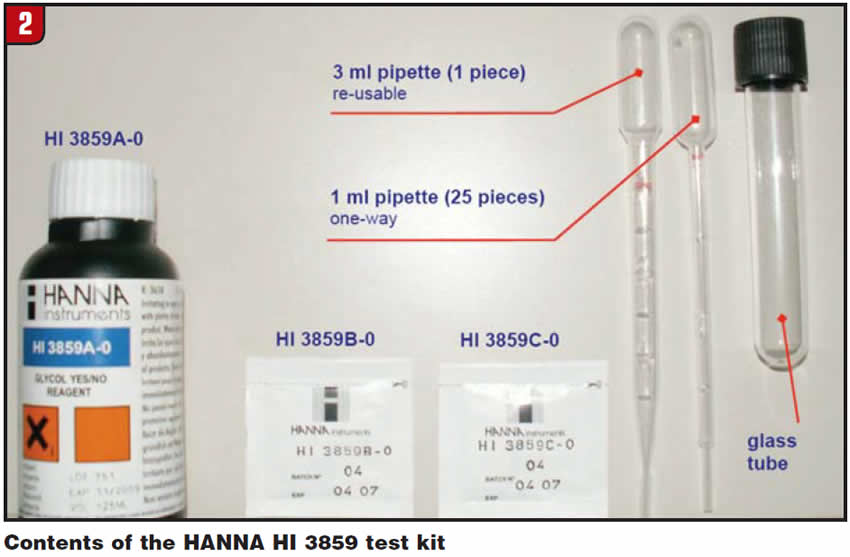

One way to prevent this whole saga is to keep a glycol test kit in your shop. A worldwide company called HANNA Instruments makes a kit for detecting glycol in aqueous and oily solutions. The HANNA HI 3859 glycol test kit (Figure 1), available through the company’s Web site www.hannainst.com/usa/index.cfm for about $130, is capable of performing 25 tests. For $5.20 for each test, it might be worth testing fluid from every glycol-equipped vehicle that comes into your shop.

Keep in mind that after a transmission has been contaminated with any type of antifreeze, it is recommended that all friction materials (clutches, bands etc.), all internal seals, all plastic thrust washers and the torque converter be replaced. If you try to shortcut in any way, trust me – it will come back to bite you. With today’s newer technology and problems anything is possible, and always remember: “Problems are not always obvious.”

Robbie Ferguson is a technical director for Alto Products Corp. and oversees all research and development of new products. He has been in the transmission industry for 15 years as a technician, rebuilder and shop manager. You can reach him at [email protected]. To learn more about Alto Products visit www.altousa.com.