Shift Pointers

- Subject: Harsh Drive engagement

- Unit: AW55-50SN

- Vehicle Application: Volvo

- Essential Reading: Rebuilder, Diagnostician

- Author: Jesse Zacarias

We can all agree that testing today’s transmissions can be more complicated then it was 20 years ago. We have to deal with more electronics and hydraulic design, not to mention programming of the transmission control module by the design engineers. Proper testing procedure and testing equipment become a necessity.

We received a call from a local transmission shop dealing with a harsh Drive engagement in a Volvo with an AW55-50SN transmission. They had replaced the valve body twice and the problem persisted. We asked them to bring the vehicle over so we could pressure-test the C1 circuit using pressure transducers. Like most recent transmissions, the AW55-50SN uses a three-phase strategy known as servo, torque and inertia phases programmed into the TCM to control the smooth garage-feel engagement. (For a more-detailed explanation see the April 2012 issue of Transmission Digest, page 10.)

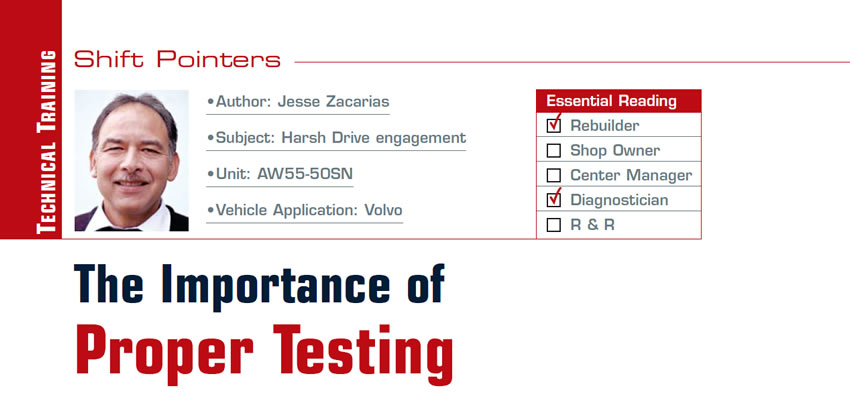

As soon as we saw the C1 pressure graph we knew something was wrong in the C1-clutch drum circuit (Figure 1). There was a sudden drop of about 20 psi at the end of the torque phase just before the inertia phase, and the torque phase was not a smooth rise as we expect to see.

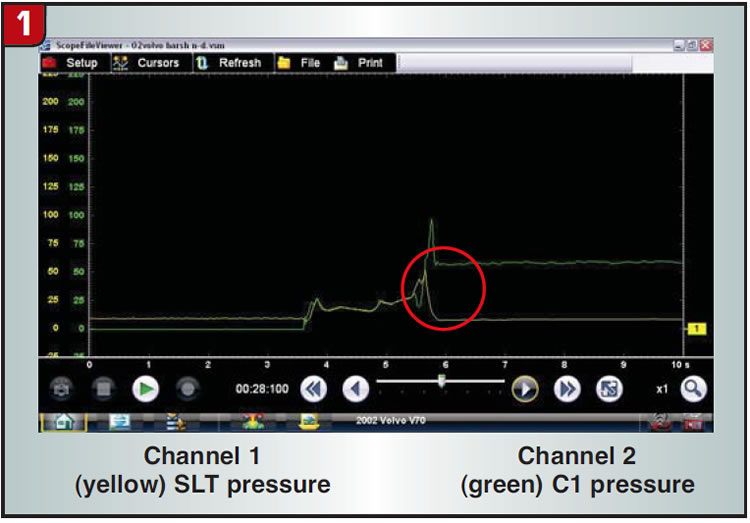

The transmission shop had informed us that they had replaced the C1 drum with a new drum. They removed the C1 drum and used a pressure regulator to limit the air pressure at the air nozzle and gradually started to apply the C1 drum with regulated air pressure. The C1 piston did not move until the air pressure reached a certain point, and then the piston would apply immediately.

This test procedure reminds us of the importance of using regulated air when air-testing the drums at the bench. If we test them with unregulated shop air pressure it may apply well, but that is not how the clutches are applied in the real world. After carefully inspecting the C1 piston they noticed that it was dragging on the drum (Figure 2).

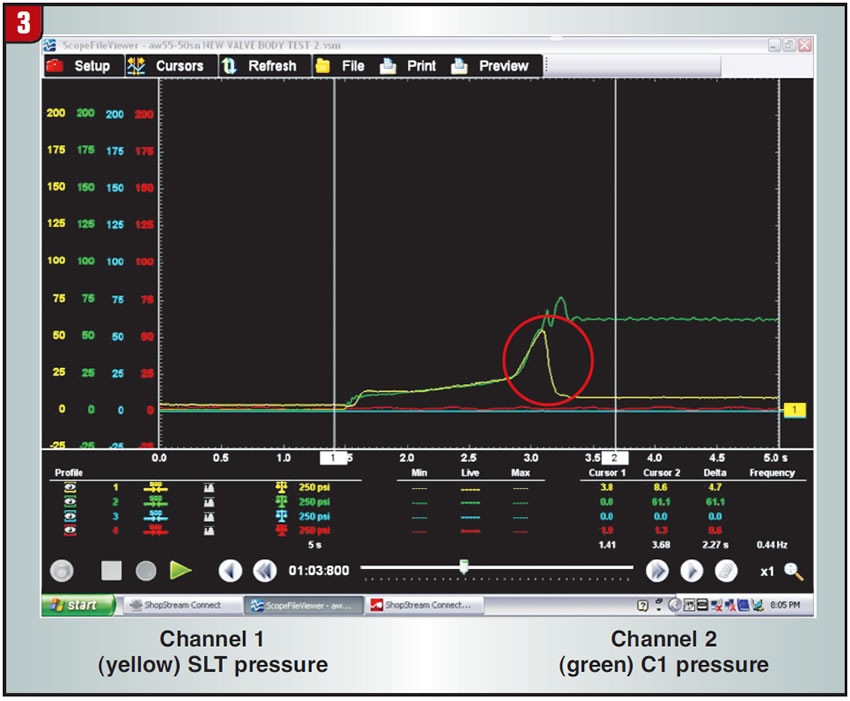

After replacement of the piston, the neutral-to-drive engagement was very smooth (Figure 3).

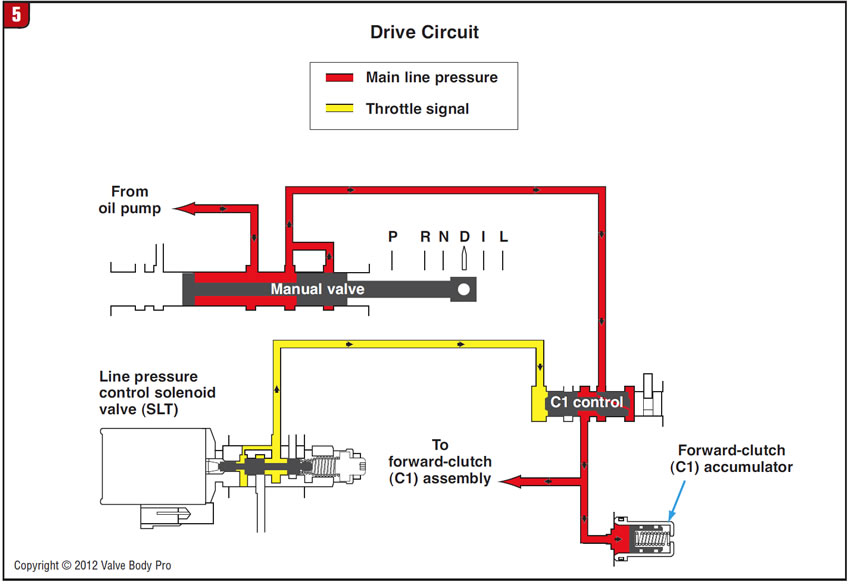

Now all this brings us back to the need for using proper testing procedures and equipment. This problem would have never been found without the use of pressure transducers (Figure 4). The old pressure gauge will not show the three phases in a way we can see. SLT pressure is what controls the apply stages of the C1 clutches.

When Drive is selected, main line pressure is directed first to the C1 control valve, where the C1 apply is controlled by the SLT solenoid (Figure 5). During the torque phase you can see SLT pressure and C1 apply pressure equal in Figure 3.

The reason the pressures during the torque phase of the readings with the bad piston were not rising smoothly (Figure 1) is that the TCM was not seeing the turbine-speed sensor drop during the torque phase of the application because of the dragging piston. This caused the TCM to increase the SLT pressure and, thus, the C1 apply pressure. With the piston replaced, both the SLT and C1 pressure rises were smooth during the torque phase (Figure 3).

For more information on the use of pressure transducers you can go to http://www.valvebodypros.com/index.php?main_page=video, where you will find two videos. One is “Pressure testing with transducers” and the other is “Diagnosing with transducers.”

Jesse Zacarias is the owner of Elec-Tran Diagnostics (www.electrandiagnostics.com) in Gilroy, Calif.