Fighting overdrive failure in Chrysler RFE transmissions can be a frustrating task. You build the unit, and a week later, it’s back with the overdrive clutches burned up again.

It happens with every one of them, from the 45RFE, 545RFE and 65RFE to the 66RFE and 68RFE. You have replaced the valve body and double-checked clearances with no problems found. To help narrow the search, we can break this problem down into three main areas: solenoid switch valve, stator dribbler valve and the clutches themselves.

Solenoid switch valve

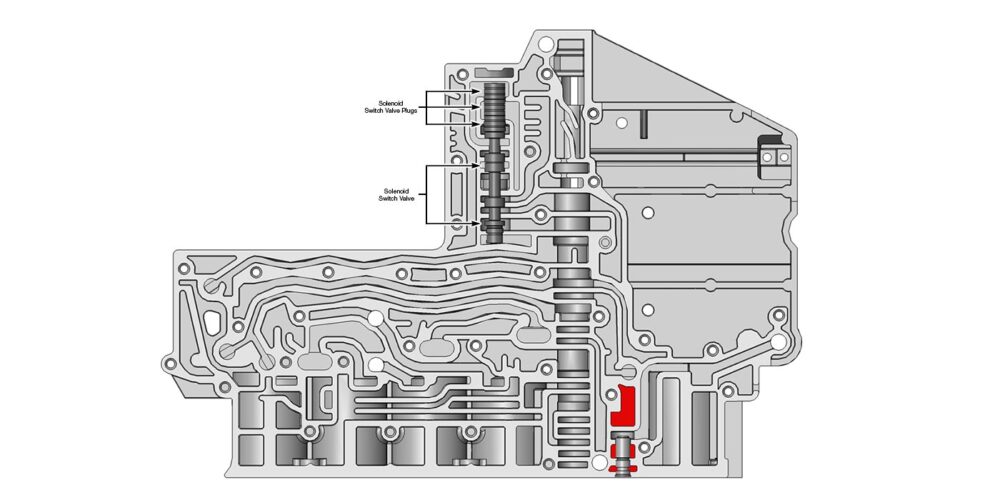

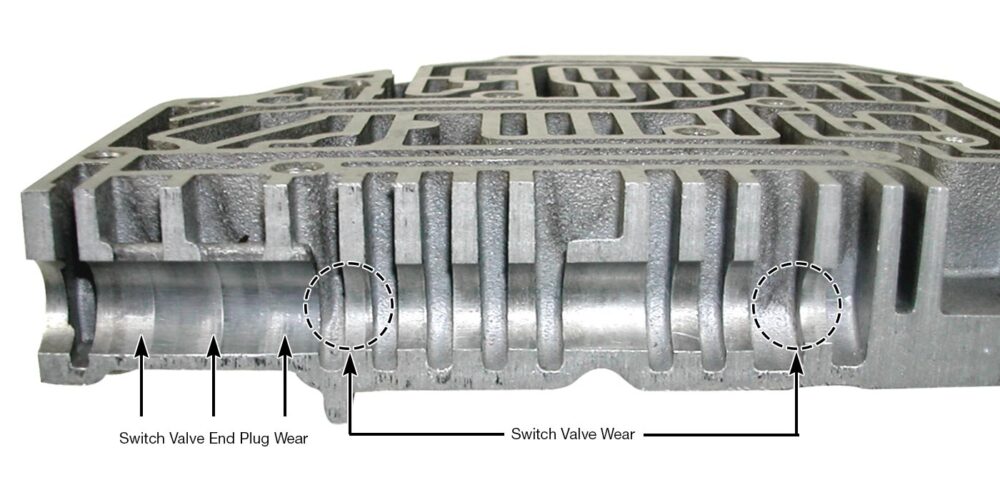

The first place to start your search is the solenoid switch valve. This area is notorious for bore wear, especially at the bore plug. There are three plugs in this location, and two of them are in motion depending on which gear you’re in (see Figure 1).

The bore plug area seems to always see the heaviest amount of wear (see Figure 2). This plug ends up switching from one side to the other.

On the 1-2 shift, the switch valve is stroked to allow fluid into the 2C clutch circuit. Then on the 2-3, the bore plug is stroked up against the switch valve. On the 3-4, the bore plug is then stroked back in the other direction to allow fluid into the overdrive clutch circuit and hold the switch valve.

So, as you can see, it’s not a matter of if you will see a problem in this area, it’s when. Vacuum testing the switch valve and plug is a quick, effective way to check whether it might be a cause of overdrive clutch failure. Testing before the job turns into a comeback can, of course, save everyone a lot of headaches. A detailed RFE vacuum testing guide that shows exactly where to test is available free at sonnax.com/vacuum-testing.

Stator

The next area to check is the stator. The overdrive dribbler valve in the stator is key to the timing of the clutches coming on (see Figure 3).

A restricted dribbler can cause a delay when applying the overdrive clutches, causing them to drag, which can lead to failure. A leaking dribbler will allow too much pressure in the circuit, keeping the overdrive clutches slightly applied, allowing them to drag and prematurely fail.

Testing this dribbler is simple: apply air pressure to the dribbler valve, and you should hear air come out of the corresponding passage. Air should travel from the pump to the drum, not vice versa. The dribbler is designed to be a controlled leak, allowing a slight amount of pressure to pre-charge the circuit. Keep this in mind when setting your clutch clearances, as shift timing is now ultimately controlled by bleed orifices and fluid pressure.

Read more columns from the TASC Force Tips series here.

Clutch pack

Finally, look at the clutch pack itself. Setting your clutch clearance to the manufacturer’s specification is key. Setting clearance too tight will cause fill time to decrease, making the clutch apply faster, which can cause a bind-up condition. Setting clutch clearance too loose will cause longer fill time and dragging of the clutches, causing them to overheat. These OE steels and frictions are already thin and won’t take the heat for long, bringing this unit right back to the bench (see Figure 4).

Some professional-grade scan tools will let you see each clutch volume index and can be useful in pinpointing problem areas.

After any repair to these RFEs, you should always perform a fast learn to make sure your transmission is recalibrated for best function. Attention to detail and proper setup on these clutch-to-clutch units is key to keeping these transmissions out of your hair.

Caleb Perham is a Sonnax automotive product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.