Shift Pointers

- Author: Jim Dial, ATSG Senior Technical Consultant

It’s 90° on a Friday afternoon. The manager calls you up to the office for a road test on one of your favorite vehicles, a 1994 Isuzu Trooper equipped with a 4L30-E transmission.

You climb into the vehicle and start it up. The first thing you notice is the pesky old Check Trans Light flashing, and, of course, it is in failsafe. You shut the vehicle off and take out your special service tool for code retrieval (paper clip), jump the diagnostic connector and count out a code 37. Referring to your electrical diagnostic information, you see that the flow-chart definition for this code is “Torque Management Serial Line Faulty.”

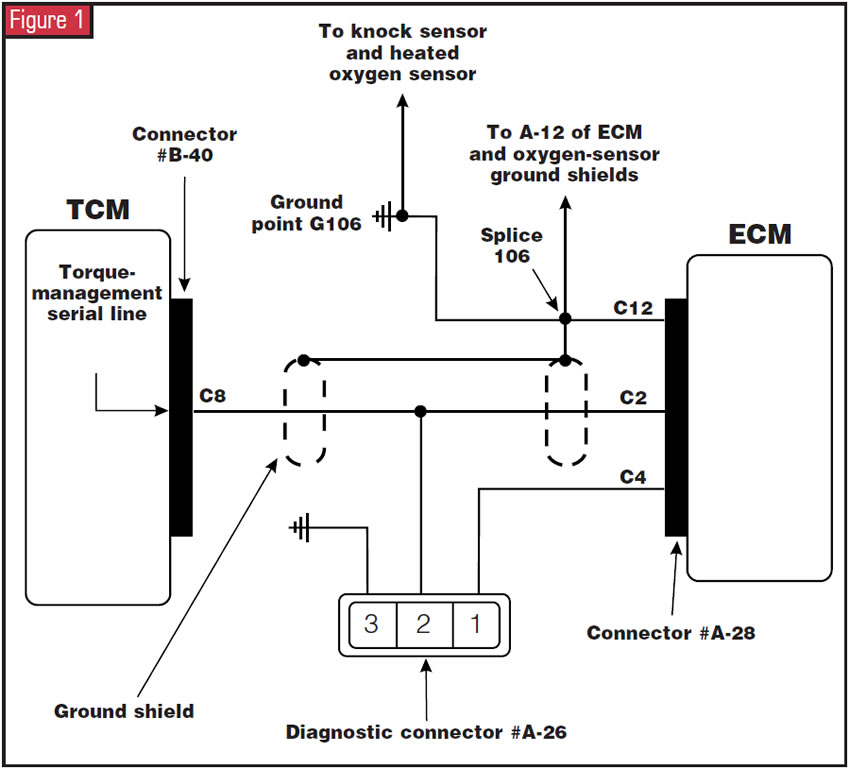

The description for code 37 says this “serial line” is the wire that is connected from the transmission control module to the engine control module and the diagnostic connector. This wire is used for torque management. How it works: The TCM delivers a spark-advance signal to the ECM during each shift, through this serial line, to reduce engagement shock. Any interruptions, shorts or opens on this line will set a code 37.

The diagnostic flow chart points to checking the wire from terminal C-8 of the B-40 connector at the TCM to terminal 2 of the diagnostic connector to C2 of the A-28 connector of the ECM (see Figure 1), looking for an open, short or continuity to ground. At the end of the flow chart you notice that the last step is, “If the wire checks good, REPLACE THE TCM.” There is also a special note in this flow chart that says code 37 also can result if the ECM does not recognize the signal from the TCM. So, I guess the simplified version of this flow chart would be that if the wire is good from point A to point B, you are left with getting out the decision maker, your trusty quarter, which is in the top drawer of your toolbox. Heads, it’s the TCM; tails, it’s the ECM!

As you can tell, many shops have played this game and have spent a bunch of money taking shots at TCM or ECM replacements, which do not always solve the problem. The root cause is actually a problem in the G106 ground point. Referring back to Figure 1, notice the dotted lines around the serial line. These dotted lines represent the ground shields, which are used to prevent external electrical interference from getting into the serial line. These ground shields are connected to a main ground point, G106, which also is used by the knock sensor, heated oxygen sensor and the ground shields related to it. A loose ground connection or a broken ground strap from the inner fender well to the engine block may allow electrical interference to enter the serial line, causing the code 37.

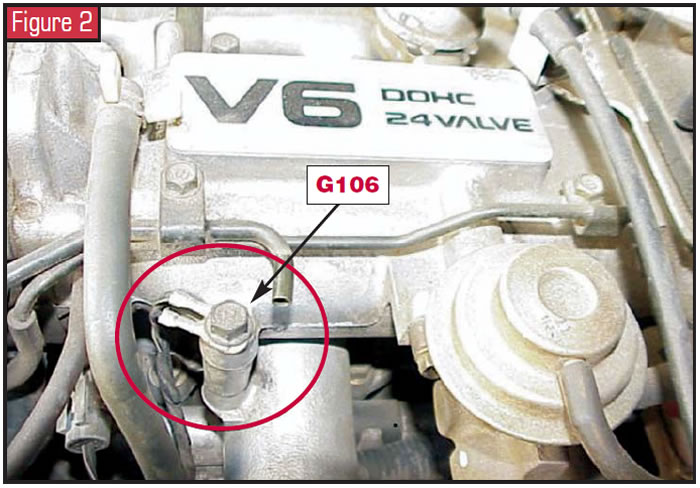

The location of G106 ground point is usually what pushes some technicians over the edge. After all, it’s a Friday afternoon and it’s 90°, and the flow chart you were working with had you checking the serial line between the ECM and the TCM, which may require a headstand on the driver-side floor for an extended period! You find that all of this checks good and that the culprit was staring at you when you opened the hood. The ground point G106 is on the plenum above the intake-air-temperature sensor, as shown in Figure 2. All that had to be done was to fix a bad connection to G106 or reconnect the grounds from an engine swap gone bad!

I hope this information will help cure some of the Trooper Blues that you may encounter along the way.

Special thanks to Patty and Brian at Ohio Transmission and Bob Sanghera for some great information that helped nail this problem down.