Up To Standards

- Author: Mike Weinberg

This being the annual edition of the magazine featuring manual transmissions, it is time to reflect on the current and future state of the manual-transmission segment of our industry.

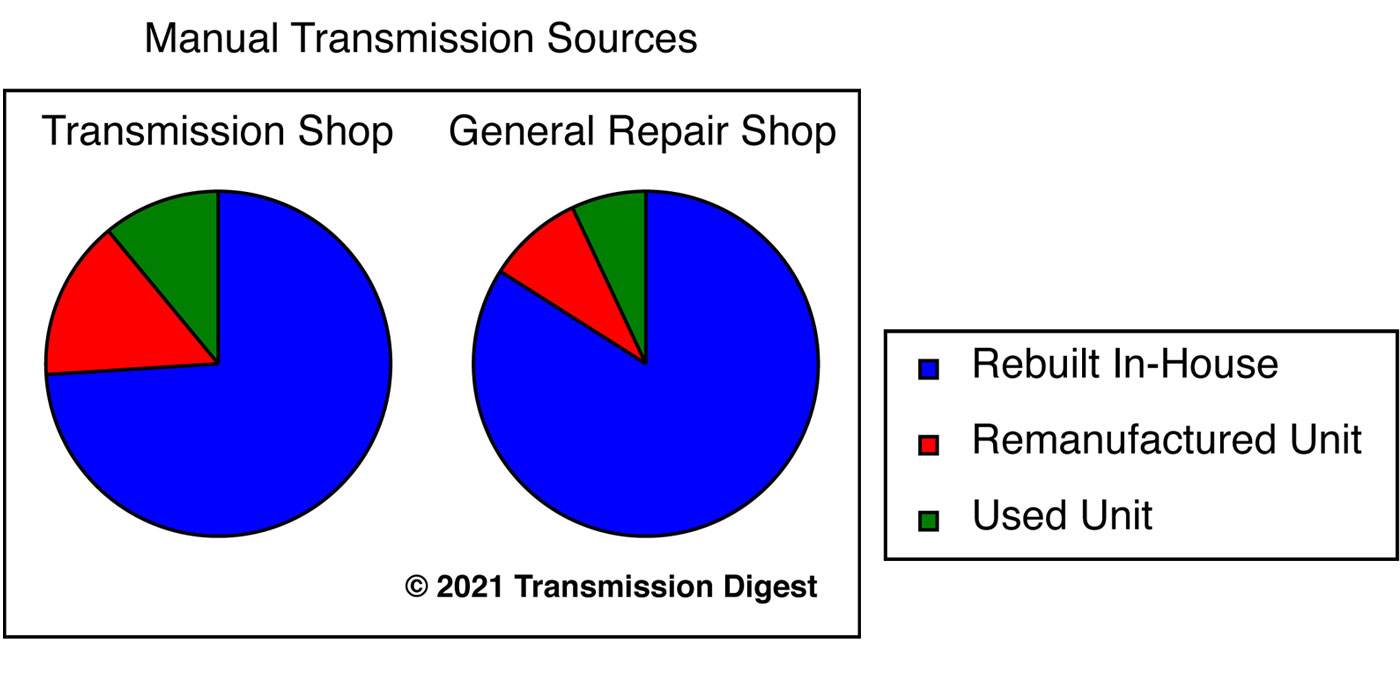

In days gone by, cars were built with manually shifted transmissions as standard equipment, and automatic transmissions were an extra-cost option. This gave rise to the term “standard” as a reference to the stick-shift transmission. Along the way, automatics have steadily gained market share and now make up about 80% of the market in the United States. In Europe the opposite is true. Automatics are slowly gaining popularity, but just a fraction of the cars on the road are self-shifting.

The auto manufacturers have made a concerted attack on market share in the transmission-repair industry. This is happening on three fronts, all of which deeply affect our profits. The first plan was the implementation of factory-rebuild programs, which typically carry long warranties. This has brought a percentage of repair work back to the dealer body and caused a consolidation in our industry. The next move by the manufacturers was to implement longer new-vehicle warranty periods on powertrain and driveline components, which also affects our industry by holding the customer captive to the dealer for up to 10 years or 100,000 miles. The third area of concern is the special deals being used to increase new-car sales. Shops all over the country are providing customers with estimates for needed repairs, only to have the customer trade in the vehicle and take advantage of “zero-down and zero-percent-interest” deals for up to 5 years. The resulting loss of business puts further pressure on our industry to find areas in which we can compete on a more-level playing field.

The manual-transmission market for the purposes of this and future discussions should be considered to include service and replacement of stick-shifted gearboxes, transfer cases, ring-and-pinion sets, axles and differentials, and manual clutches. This constitutes a market in which the manufacturers do not compete because the smaller volumes of units generated prevent them from using the huge economies of scale they have with automatic units. This means that they are not setting the market prices as they do with their automatic-transmission programs.

A few years back, various experts were prognosticating the demise of the manual market. I am happy to report that they are way wrong. Several factors are at work to ensure the growth rather than further decline of the manual market.

The trend that started with the huge demand for sport/utility vehicles continues unabated. A secondary effect is the trend toward all-wheel-drive vehicles, which ensures large volumes of transfer cases and all-wheel-drive units to work on. The transfer-case market has grown beyond all expectation, and this growth can be expected to continue for the foreseeable future.

The next area of interest is the so-called “clutchless” manual transmission. This is a misnomer, as vehicles with these units are equipped with clutches but do not have a clutch pedal. The clutch is engaged and controlled electronically. Many of these vehicles have so-called “paddle shifters” on the steering wheel and permit the driver to take off in 1st gear without using a clutch pedal. By touching paddles or buttons on the steering wheel or using the shift lever on the console, the driver can upshift or downshift at will. The electronic controls regulate clutch application and prevent over-revving on downshifts, making it easy for a less-skilled driver to enjoy more control over the vehicle.

These units started out in Formula One race cars and have trickled down into street-driven vehicles. As is usual, the first “clutchless” units appeared in high-line cars such as Porsche (Tiptronic), Ferrari and Aston Martin. This year the BMW M3 has this setup and is a lot of fun to drive. I am told that this type of setup is on the drawing board for the Ford Mustang and other popular performance-based cars that the common man can afford.

Tremec, Spicer and Eaton have developed the same type of system for light-, medium- and heavy-duty trucks, which will increase in popularity because of increased fuel savings and ease of operation for the driver. In these commercial applications, the computer-controlled manual gearboxes can select ratios on the basis of data acquisition to provide fuel economy and efficiency far beyond the capability of even a skilled driver.

In the words of Bob Lutz, one of this era’s automotive-manufacturing gurus, “People want to be reunited with their cars.” The huge popularity of racing as a spectator sport has translated into increased demand by the motoring public for performance-oriented vehicles. The days of muscle cars with huge engines are gone forever, but the new generation of vehicles offers great performance and handling and excellent fuel mileage, and the fun factor is back in cars.

What does this mean for us who earn a living repairing transmissions? The future will bring an advanced learning curve for diagnosis and electronic systems related to standard transmissions and transfer cases. Access to information and the desire to learn will be a necessity.

I hear many people in our industry who tell me they “don’t do sticks.” What does that mean? Does it imply that they don’t do clutch replacement? Probably not, but if you do clutches, you can replace a transmission. If you don’t wish to rebuild manual gearboxes, there are any number of quality vendors out there from which to buy reman units. Does it mean they don’t do ring-and-pinion work? This is arguably the easiest and most-profitable repair on the vehicle, Does it mean they don’t work on transfer cases? I doubt that that is possible, as the transfer case or all-wheel-drive system is used behind both manual and automatic gearboxes, and no one can pass up that market.

The next profit center open for discussion is “value added.” To survive in this market you have to make the right profit margins, and one of the best things you can do for your profits is learn to sell more-profitable items. The performance market is huge and growing, and you should be taking advantage of it. The difference here is selling customers something they want to buy instead of have to buy.

Every day you deal with people who come in with a problem that turns out to be expensive and upsets their financial world. They are not happy and sometimes take it out on you, the messenger. When you sell value-added items, you are dealing with people who want to spend money on their vehicles to have the latest and greatest. High-performance upgrades to gearboxes, ratio changes to final drives or differentials, upgrades to performance-clutch replacement sets, bullet-proof CV joints and axles all provide the customer with satisfaction while your profits increase.

There is a huge market out there with young people who will sleep in their cars to afford the upgrades that will give them the performance they desire. Everyday I get passed by some youngster driving a little rice burner with a super trap muffler mounted on the back and an aggressive attitude. It isn’t 10,000 watts of stereo anymore but adding getup-and-go to these vehicles that will help ensure your future.

The manual-transmission market is growing, and it offers you a chance for increased profitability without a major financial investment. There is a learning curve, but this business has always demanded continuous training, and to be current you must keep up on all systems in the car. The race has already started; don’t get left on the grid while the rest of the field takes off.