Shift Pointers

- Subject: No movement

- Unit: A350E

- Vehicle Application: 1996 Lexus GS300

- Essential Reading: Rebuilder, Diagnostician

- Author: Charlie Rakes

I have always loved the challenge of working on those “puzzlers.” So, when one came to my bench recently I knew I would definitely take the challenge.

This was the day the 1996 Lexus GS300 with an A350E transmission came as a tow-in with no movement.

Here it begins. I lowered the pan to find a lot of metal, as well as tons of friction material within the pan. Of course, the transmission came out.

The shop had contacted the customer and received the OK to remove the transmission. What was not known became a task at hand. The transmission came to my bench with the authorization for the teardown of the unit.

With the teardown, I found that the overdrive planetary, sun gear and overdrive drum were blown; the clutches and bands were burnt; and the valve body was loaded with metal. The customer was contacted and gave the OK to rebuild the transmission.

I had thought I had a lot of hard parts to use in the repair because we had a lot of A340E cores. Then I found that the hard parts in the A340E are different from those in the A350E.

In the A340E, the reluctor on the overdrive drum has only 16 teeth; in the A350E it has 32 teeth (Figure 1).

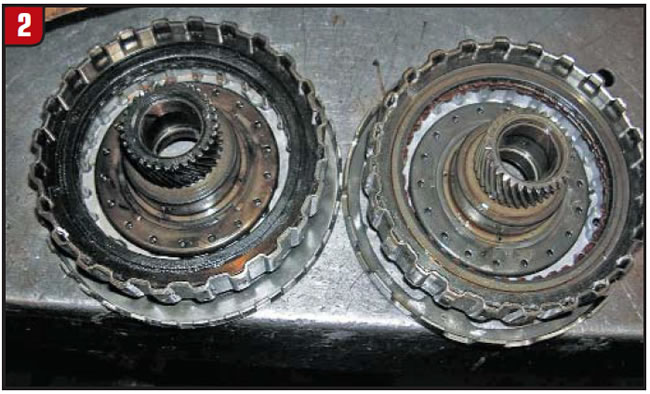

The overdrive sun gear in the A340E has 31 teeth, and in the A350E it has 33 (Figure 2).

The A340E input shaft is about 83/4 inches long; in the A350E it is about 81/8 inches (Figure 3).

Always remember that you must match the stator shaft with the proper input shaft.

Now the hard parts were calculated and I could rebuild the unit. I rushed into assembly. I put in a new master kit and overdrive hard parts; opened the valve body and thoroughly cleaned out all the metal remnants; and freed all valves. Then I installed the valve body back into the transmission, and with a new torque converter the transmission was installed.

It was time for the road test. Now other problems came up.

The transmission was a champ but every now and then would have second-gear starts, and I had to solve this. I continued the road test to see how a longer drive would affect the Lexus.

I came back in and detected a shift-solenoid code, so now the car was back on the rack. I pulled the valve body out to find the 1-2 shift valve stuck. I freed the stuck valve, grabbed a new solenoid, flushed the other solenoids and reinstalled the valve body.

Upon testing, I kept coming up with DTC P0715, OD direct-clutch speed sensor. When fifth gear was commanded it would make a quick upshift, then downshift. As I pressed the overdrive button to engage OFF the unit then upshifted. So, in non-technical terms, this “puzzler” was working backward, basically.

With the overdrive direct-clutch speed sensor replaced, the problem was still there along with DTC P0715.

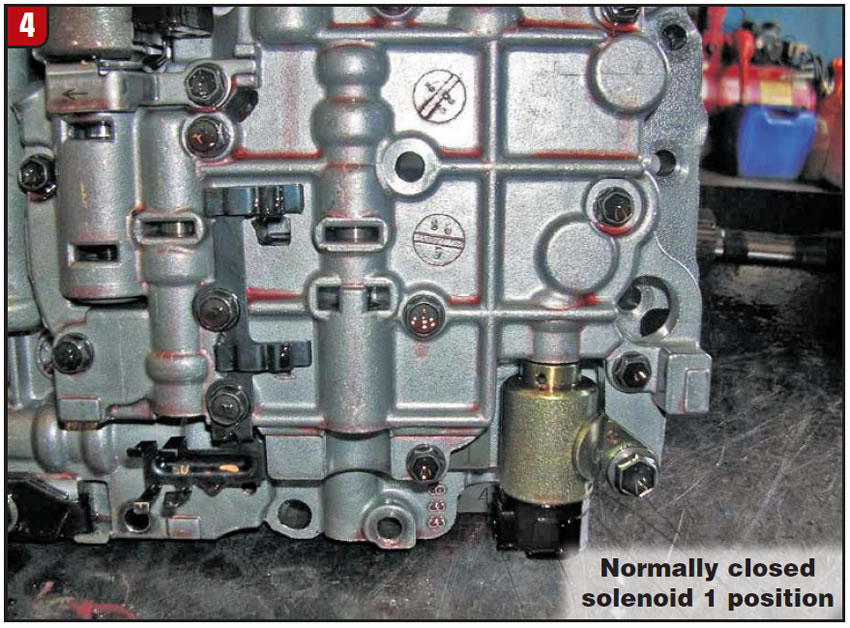

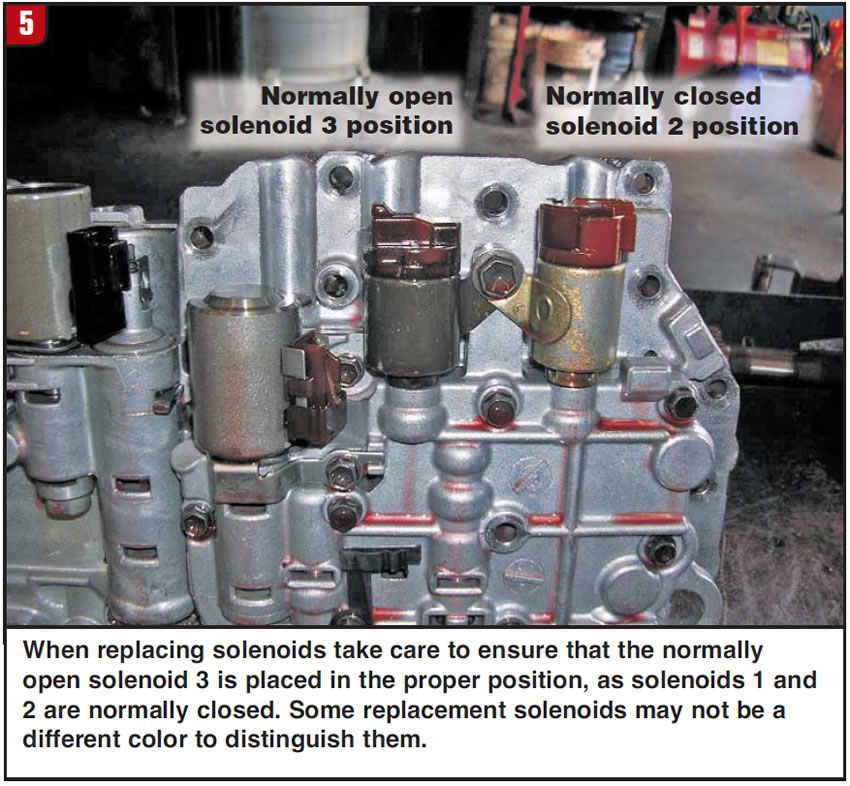

I then removed the valve body and went through it but found nothing wrong. I checked solenoids 1, 2 and 3 (figures 4 and 5). What I found was normally closed solenoids 1 and 2, and normally open solenoid 3. That meant the solenoids must be in the wrong positions, right? Well, there is no information on which went where. On rebuild the 1-2 shift solenoid was changed, which made all three solenoids as closed.

Of course, we need one solenoid open, and finding it was now the task.

I then put the valve body back into the car with a normally open solenoid in the #1 position and normally closed solenoids in the #2 and #3 positions.

The overdrive problem was solved, but now there was no reverse. I thought to myself, “I will get this ‘puzzler’!”

The pan came back down. Now, I put the normally open solenoid in the #2 position with the normally closed solenoids in the #1 and #3 positions.

The puzzle returned. Now I got reverse back – along with the overdrive problem and the code for the OD direct-clutch speed sensor.

Again, the pan came down and I put the puzzle together: normally closed solenoids in the #1 and #2 positions and the normally open solenoid in the #3 position.

On the last pan drop I noticed friction material in the pan, so to be sure I had the installer remove the transmission just to check it. I found that my solenoid episode had burned the forward frictions, so I replaced them. The transmission was installed and everything worked great.

Problem solved! Overdrive was back and so was reverse. What a great day!

Charlie Rakes is a transmission rebuilder at AA Quality Transmissions in Stuart, Fla.