Shift Pointers

- Subject: Problems caused by mismatched speed sensors

- Unit: GM 4L80-E, Ford 4R70E/4R75E

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

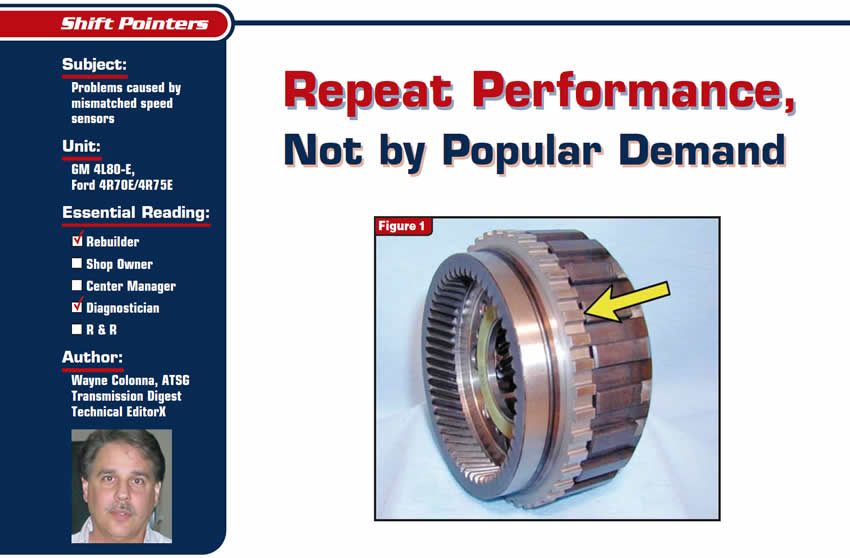

You may recall that the 4L80-E made its appearance in 1991. And whether it was in two-wheel-drive or four-wheel-drive configuration, the output carrier had the exciter ring for the output-shaft-speed (OSS) sensor pressed onto it (see Figure 1).

At the beginning of the 1994 model year all four-wheel-drive applications had the OSS sensor relocated to the transfer case and the speed-sensor ring on the output carrier eliminated. During early production of this change, GM poked a good working sensor into the hole on the main case to serve as a plug until it began installing plated-steel bore plugs that look similar to freeze plugs.

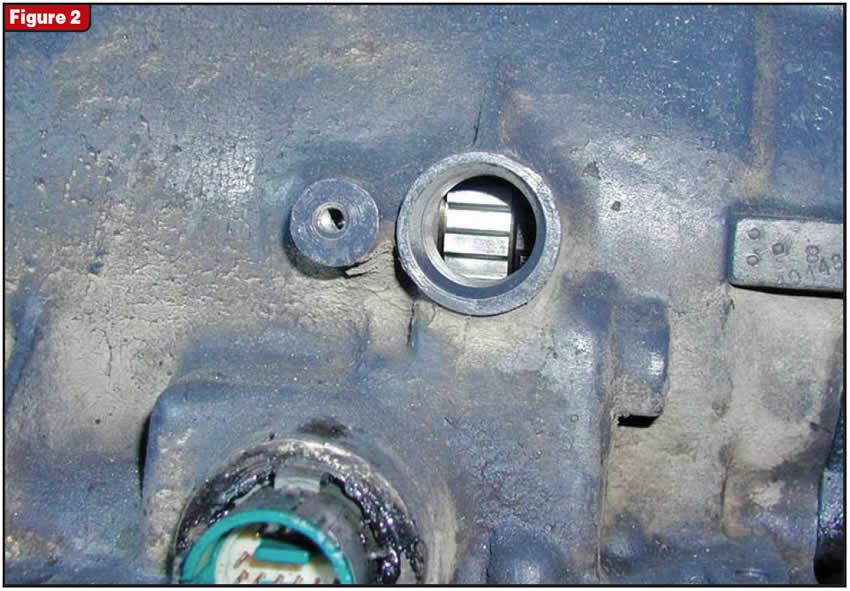

But soon after this change took place, there were times when the output carrier without the sensor ring would be reused in two-wheel-drive applications, which required the sensor ring. Interesting enough, the park lugs were close enough to the OSS sensor that a signal was produced, but when it should have read 12 mph it read about 6 mph – about half the correct speed, and as you can imagine (or have experienced) the shifts were very late. Usually the digital ratio adapter controller became suspect and the shop would replace it, only to have the same problem occur. In some instances we have even heard of the computer being changed in an attempt to resolve the problem when all along it was a case of a missing speed-sensor ring, which could have been easily detected by pulling out the OSS sensor and looking into the hole to see whether the sensor ring was there (see Figure 2).

That was then, and every now and again it still occurs, but history has been known to repeat itself. Case in point: We are now experiencing similar repeat performances with Ford’s new 4R70E/4R75E transmission. 2004 and newer units received a turbine-shaft-speed sensor (see Figure 3) that reads the projections off the forward-clutch drum through a non-ferrous sun shell. At the same time the design of the ring gear changed from holes that excited the OSS to extended lugs now used to excite the OSS (see Figure 4).

As you can see there are more lugs than holes. If the later ring gear is used in earlier applications along with the later OSS, rapid upshifts will occur. The previous-design OSS is longer and will make contact with the extended lugs on the newer carrier (which should provide a clue), so overcoming the problem by using the later OSS that is shorter to accommodate the extended lugs is definitely not the answer. The result, as previously mentioned, will be rapid upshifts. But if the early-design ring gear is used in a later application, a late-shift problem similar to that in the 4L80-E will occur with the 4R75E transmission. A repeat performance, not by popular demand!