R&R Tech

- Author: Barry Bartlett

- Subject Matter: Drivability

- Unit: CVT

- Vehicle Application: 2007 Nissan Maxima

- Issue: Lack of acceleration

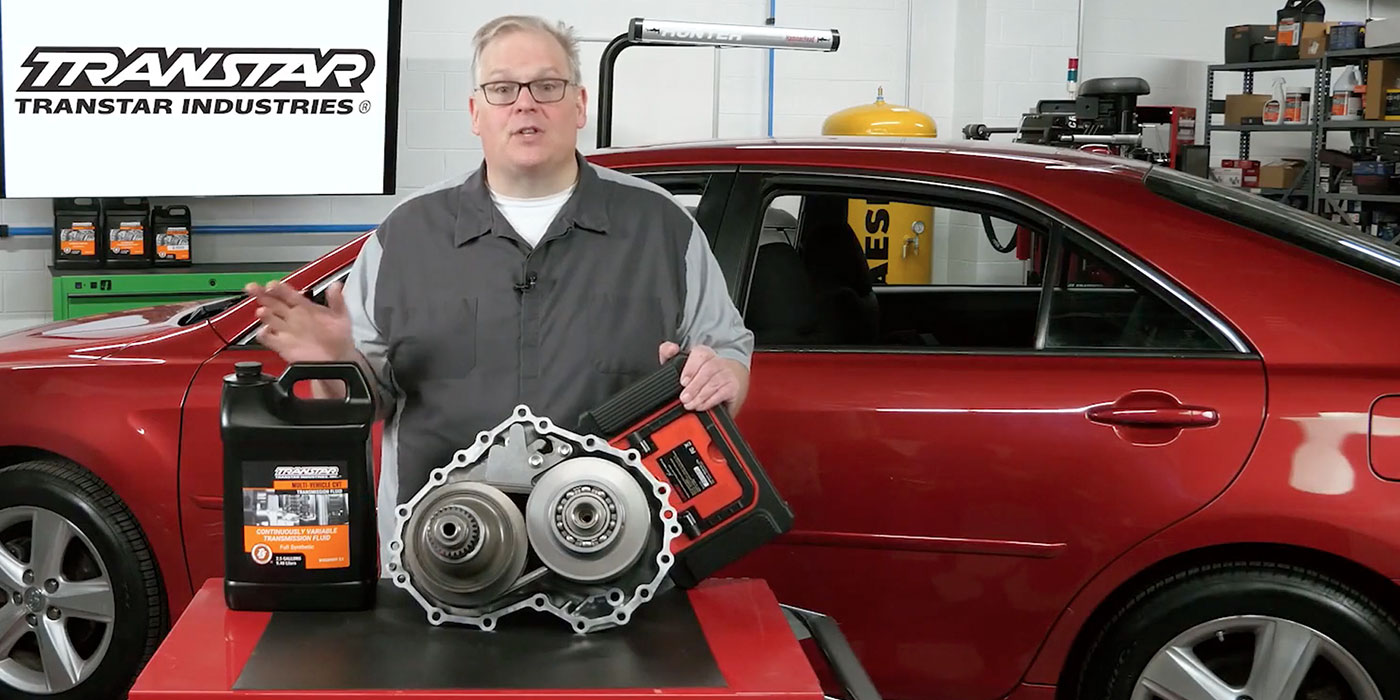

My first encounter with a Nissan CVT was an interesting experience. Our wholesale customer had diagnosed the transmission as being bad, so the transmission was then replaced. After replacement, the vehicle owner said the car would not accelerate beyond 40 mph. Since the installed transmission was purchased from us, it then became our responsibility to find the root cause of the problem and get the transmission working properly. We verified the customer’s complaint with the initial road test and then began diagnosing the cause.

There were no codes in the PCM, TCM or any other modules. The tire-pressure-monitor light was on. Upon checking into the cause of this, we discovered that the sensor in the right-rear tire would not initialize and was causing the warning lamp to remain on.

When I road-tested the vehicle, I found that it would change ratios up to about the 4th (0.7 ratio) gear range but would not change beyond that ratio in the manual-shift position (it has six range positions; the highest is around 0.4 ratio). The indicator in the dash would show 5th and 6th ranges when manually commanded, but there was no change in ratio, resulting in engine speed of 3,000 rpm at 50 mph. It would start out at a ratio of 2.37 and increase to a 0.7 ratio with a step-motor reading of -6 to 169. Per the service-manual specs, the step motor should have a range of -20 to 190 with a gear-ratio range of 2.37 to 0.43. I did have converter lockup about 10 mph, which is common on CVTs, but could not get the ratio past 0.7, or equal to the 4th range.

After researching the service manual, I found that initialization of the TCM is required after a transmission replacement. I then performed the initialization routine and, surprise! I lost converter lockup. During the initialization process the instructions direct you to go to the calibration screen. Next, you copy all the numbers down, then do the initialization and return to the calibration screen and compare to see whether the numbers have changed. If the numbers changed, the initialization was completed properly. In my case, the numbers changed, sure enough. However, the numbers changed to all letters – specifically, F!

Looking at the parameter identification data (PID), everything looked OK except that the transmission-temperature value on the screen was about 100°F too high. On a road test it displayed 300°F, but when I checked the pan with an infrared thermometer, true fluid temperature was only 170°F. I also discovered that the actual sensor voltages were correct, but the scanner was displaying the PID voltages incorrectly.

At this point I decided to take it to the Nissan dealer and have the TCM re-flashed, hoping it might solve the problem. I was informed that the PCM had the most-current calibration but that the TCM needed updating. The dealer performed the TCM re-flash, and I thought my problems would be gone. Unfortunately, the vehicle still had the same 40-mph limitation and still had no converter lockup.

We then searched and found a used TCM in an attempt to determine whether the TCM was at fault. After we installed the used TCM the converter lockup resumed, but the ratios we had hoped to see just weren’t correct. On the next road test it still had a 0.7 ratio at 3,000 rpm while traveling 50 mph. Again, per the recommendation when you’re changing the transmission or installing a used TCM, the service manual instructs you to do an initialization. The definition of insanity is to do the same thing over and over but expect different results, so guess what – I did the initialization, and surprise! No converter lockup! Lesson learned: On the CVT TCM, do not do an initialization!

I contacted ATSG, but they hadn’t had much experience with the Nissan CVT and didn’t have much more information than I had gathered in my research. However, the technician I talked to said he could not see the need to initialize the TCM. Since there are no gear changes as in a traditional-type transmission, and it has only two variable pulleys that change diameter as the stepper motor moves them on a kind of fulcrum, there is no need to relearn volumes of clutches or shift timing.

We picked up another used TCM but did not perform the initialization. After installation the TCC lockup came back, but we still had issues with incorrect ratio and stepper-motor values.

I spent a late night on the Nissan website and read everything I could about this transmission and searched iATN for any suggestions that might be of value. I saw some that had antilock-braking and engine drivability problems that caused shift issues, particularly weak wheel-speed sensors that can affect throttle control yet will not set a code. One easy way to check whether the ABS is affecting a drivability issue is to disconnect the ABS module and drive the vehicle. You will lose speedometer functionality, but if the drivability issue disappears you then know that the ABS is the cause. In my case, disconnecting the ABS module did not improve the issue.

The next morning I started browsing through all the data in each module and noticed that, when the vehicle was cold, the engine temperature showed about 60°F but the intake-air temp showed 98°F. The MAF grams p/s was in range with no codes, and the engine ran fine. Still, the intake-air-temp reading was almost 40°F off.

We picked up a used mass-airflow sensor from a salvage yard for $50 and installed it. On the road test PID displayed a 0.48 ratio with a stepper-motor reading of 175, and with a speed of 60 mph the engine speed was 1,800 rpm. All systems now appeared to be normal, and in the end the customer left pleased to have a fully functioning vehicle again.

After discovery that the MAF sensor was the root cause of the problem, I learned the moral of the story: Because of the information that is shared across a CAN-bus system, sensors and inputs that affect one electronic subsystem can have a direct impact on another subsystem. Therefore, to effectively diagnose these types of vehicles, you need to “look outside the box,” so to speak, and investigate other systems that might be causing your issues. You might be surprised at what you find.

Barry Bartlett has worked in automotive diagnostics and repair since 1967 and has been with Certified Transmission for three years, currently as a shop foreman. He is an ASE Master Technician with L1 Advance Level certification.