Issue Summary:

- A broken front planetary in the Chrysler A518 (46RH) or 46RE before or after a rebuild, especially on vehicles equipped with diesel engines, usually is caused by not enough torque capacity with the four-pinion carrier. The five-pinion carrier is recommended for diesel-equipped trucks.

- After a rebuild on a Saturn, the vehicle exhibits erratic shift patterns. It may shift from 1st to 3rd with no 2nd and 4th or may start in 2nd with no 1st or upshifts to 3rd or 4th. This condition usually occurs after one complete upshift pattern, from 1st through 2nd and 3rd to 4th. The cause may be a mismatch of geartrain parts.

- We have further information on Ford/Mazda CD4E/LA4A-EL problems with front-seal blowout or a constant front-seal leak. This leak can occur even though the engine is NOT running. This bulletin covers the steps to be followed to correct this problem.

Before and/or after rebuild, the vehicle returns with the front planetary carrier broken. This will occur more frequently in vehicles equipped with diesel engines.

Not enough torque-carrying capacity with previous-design aluminum four-pinion carrier.

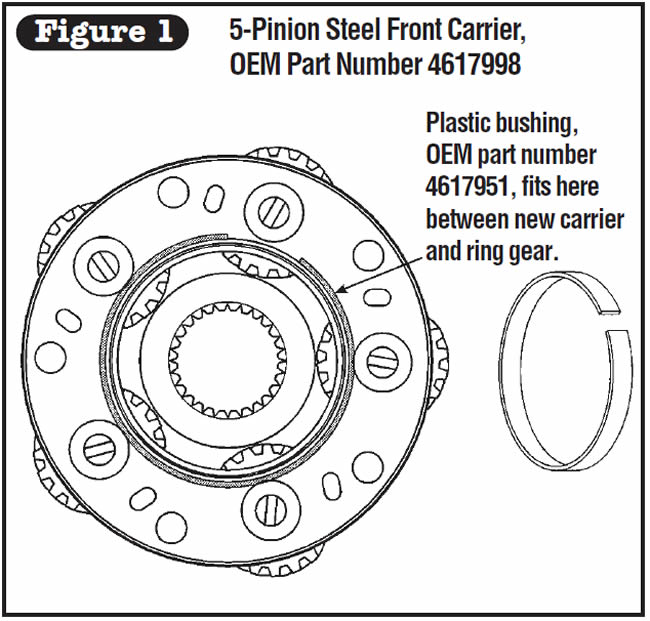

Now available under OEM part number 4617998 is a new-design five-pinion steel front planetary carrier (See Figure 1).

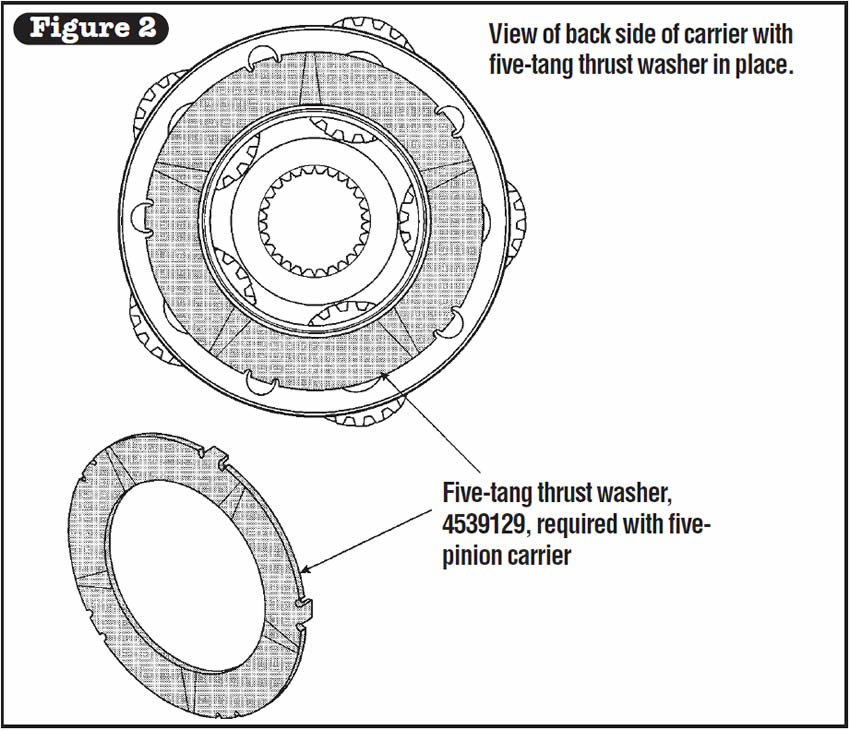

The five-pinion steel front carrier also requires a plastic bushing, OEM part number 4617951, that fits between the new carrier and the previous ring gear (See Figure 1), and a five-tang thrust washer for the back side of the carrier, OEM part number 4539129, as shown in Figure 2. These parts should be installed in all vehicles equipped with diesel engines and any vehicle carrying heavy loads.

- Front Planetary Carrier, Pinion Steel . . . . .4617998

- Thrust Washer, Tang . . . . . . . . . . .4539129

- Plastic Front-Carrier Bushing . . . . . . . . . .4617951

After rebuild, the vehicle exhibits one of the following erratic upshift patterns:

- A. Shifts 1st to 3rd, with no 2nd or 4th.

- B. Starts in 2nd, with no 1st, and upshifts to 3rd and 4th

- C. Shifts from 1st to 4th, with no 2nd or 3rd.

This condition usually occurs after one complete upshift pattern from 1st through 2nd and 3rd to 4th, and one or more of the following diagnostic trouble codes (DTCs) normally will be stored, depending on the particular gear-ratio error:

1991-95 Model Years:

- DTC 16 = No 1st Gear

- DTC 18 = No Gears Available

- DTC 22 = No 2nd Gear

- DTC 23 = No 3rd Gear

- DTC 24 = No 4th Gear

1996-2000 Model Years:

- DTC P0730 = No Gears Available

- DTC P0731 = No 1st Gear

- DTC P0732 = No 2nd Gear

- DTC P0733 = No 3rd Gear

- DTC P0734 = No 4th Gear

These DTCs may be set after replacement of the complete transaxle assembly, replacement of individual gear components or reprogramming of the PCM.

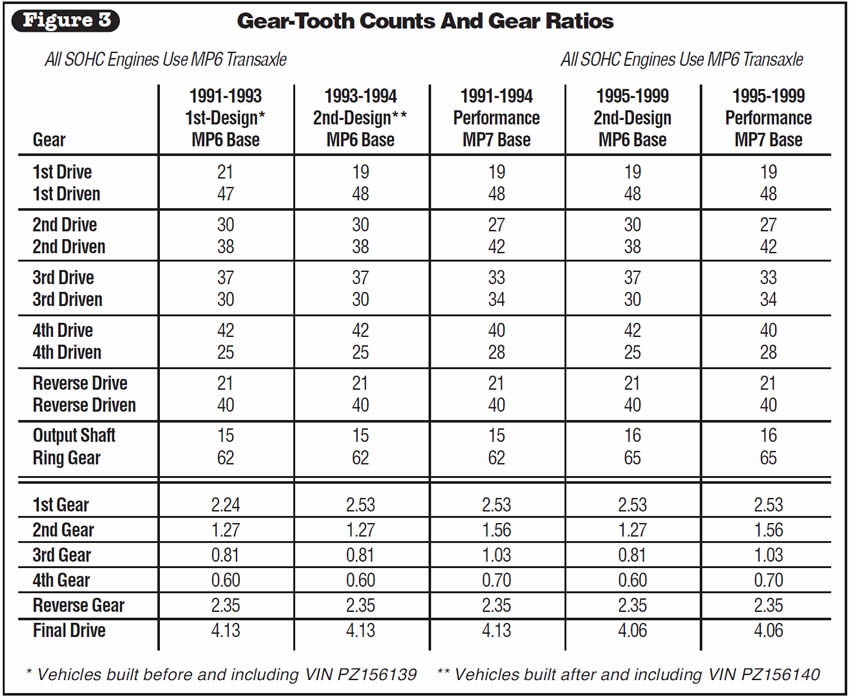

The cause may be a mismatch of geartrain parts (drive and driven gears) between the 1st-design MP6 base transaxle and the 2nd-design MP6 base transaxle or MP7 performance transaxle.

Another cause may be incorrect calibration installed because of a wrong VIN in the PCM. If the wrong calibration has been installed, the PCM may use a gear-ratio table that will not match the actual gear ratios, causing DTCs to be set.

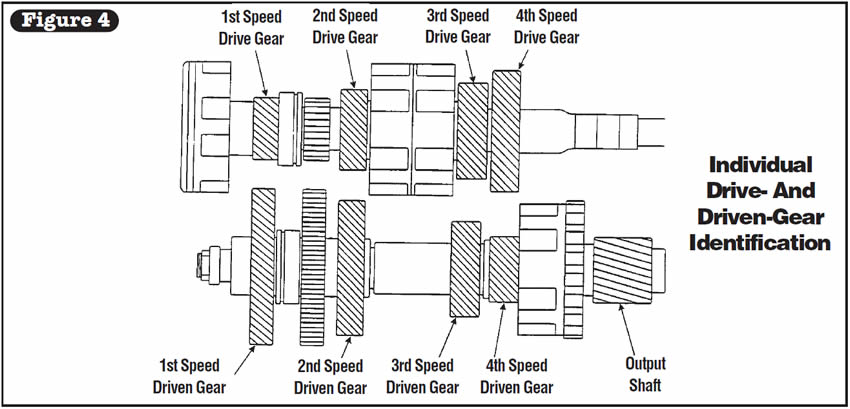

When you’re rebuilding a Saturn transaxle and geartrain replacement is necessary, ensure that the replacement gears have tooth counts identical to those of the originals. Refer to the chart in Figure 3 for the proper gear-tooth counts for the model that you are rebuilding and to Figure 4 for the locations of the gears.

Important Note:

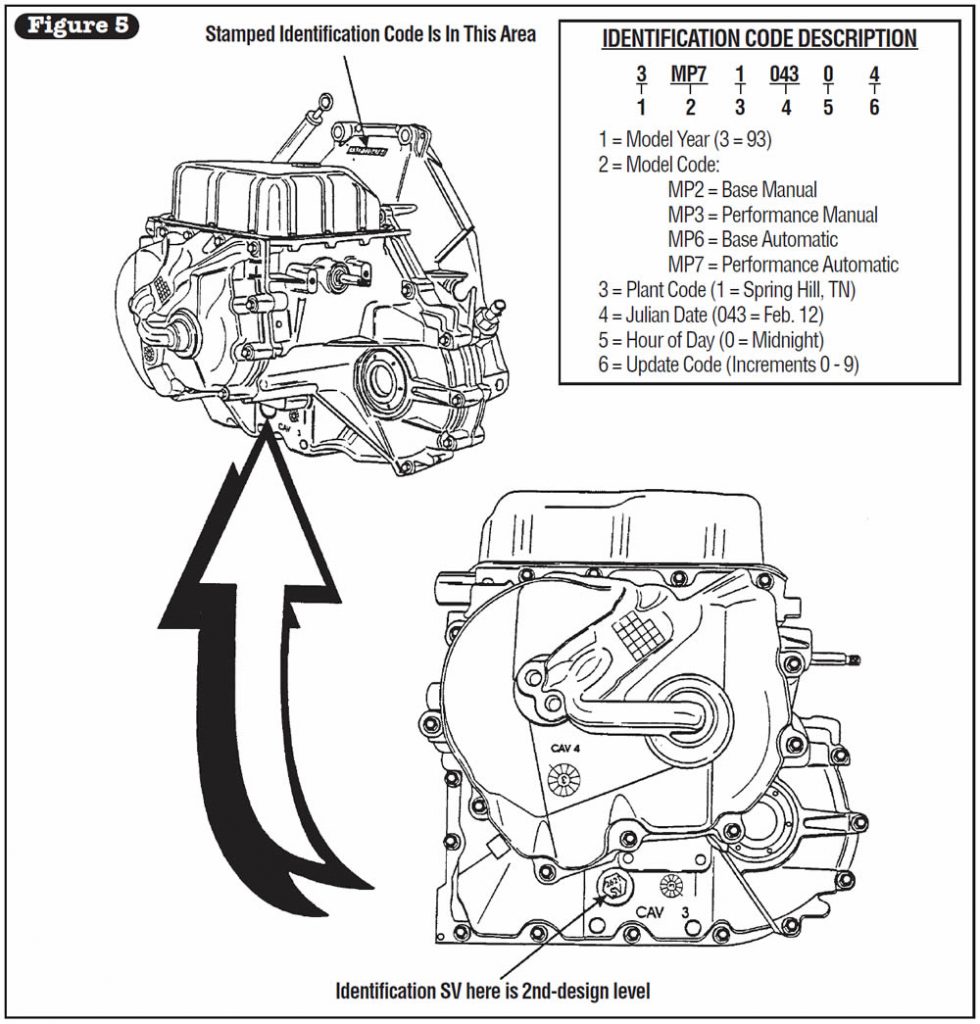

See Figure 5 for identification of the transaxle design level and type of transaxle. The identification codes follow:

- MP6 Base = 1st Design

- MP6 Base (With SV) = 2nd Design

- MP7 = Performance Version

If an incorrect calibration or VIN information has been written to the PCM, reprogram the PCM with the proper VIN and calibration information. Compare the VIN plate on the dash to the VIN identified in the PCM and make sure they match.

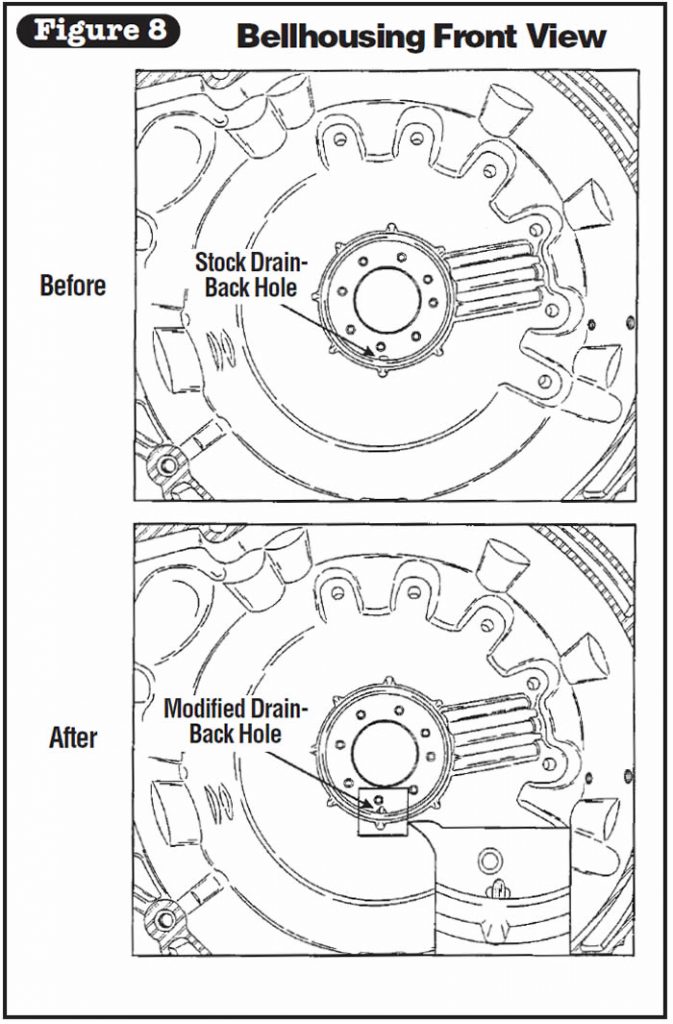

Vehicles equipped with CD4E/LA4A-EL transmissions may exhibit repeated front-seal blowout or constant front-seal leak, and possibly constant leak out the front with-out the vehicle even running.

One cause may be an undersized front-seal drain-back passage in the bellhousing, and another cause may be that the wrong torque converter was installed.

Follow the steps listed to correct this condition:

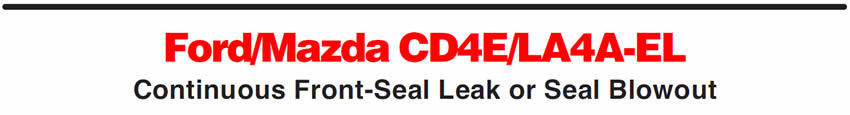

(1) Remove the stator from the front of the bellhousing. Remove the area highlighted in gray in Figure 6 with a bench grinder.

Note: Heating the bellhousing in a parts washer will ease stator removal.

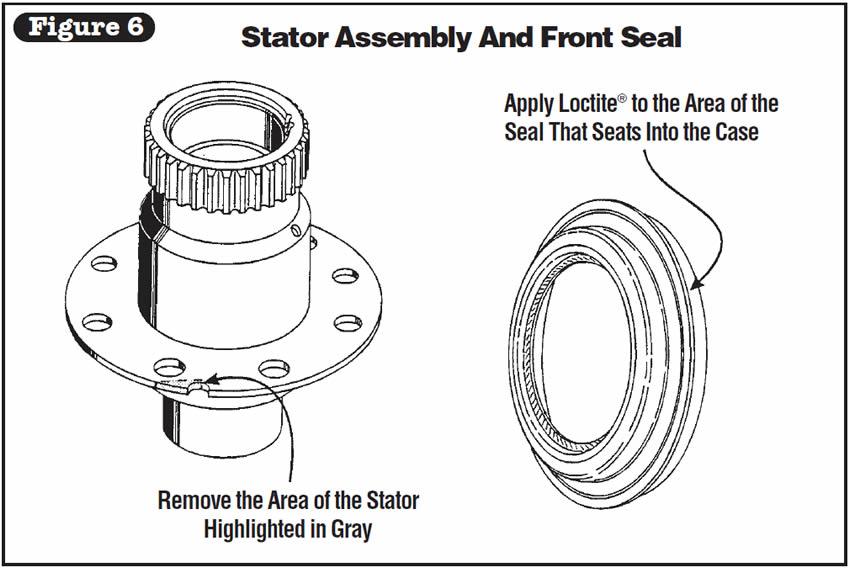

(2) With a 3⁄16-in. or 13/64-in. drill bit, drill at an angle through the area shown in Figure 7.

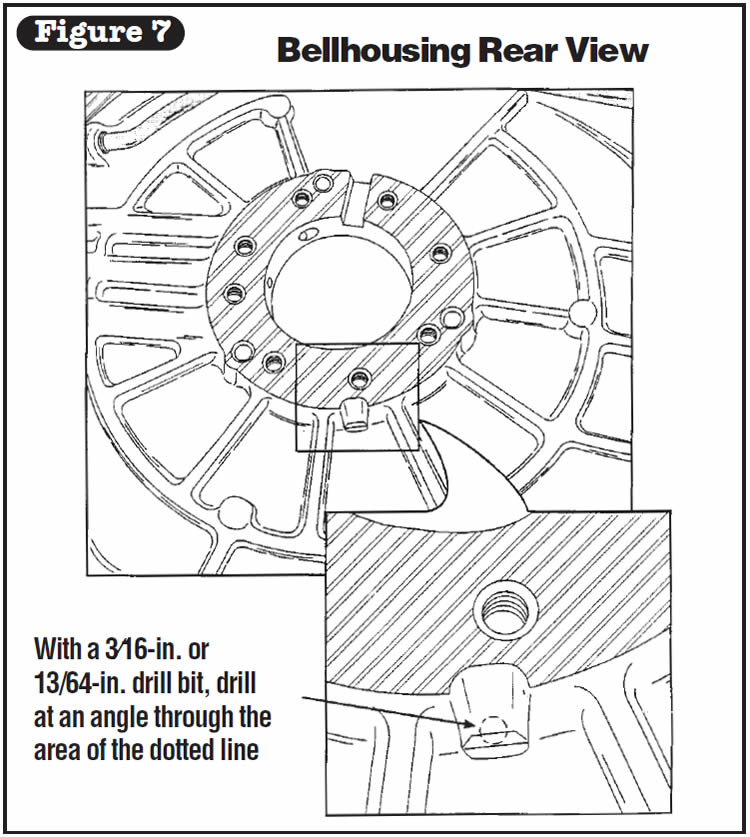

(3) Refer to Figure 8 to see the modified drain-back passage from the front side of the bellhousing.

(4) Apply Loctite to the front-seal outer diameter before installing it in the bellhousing (See Figure 6).

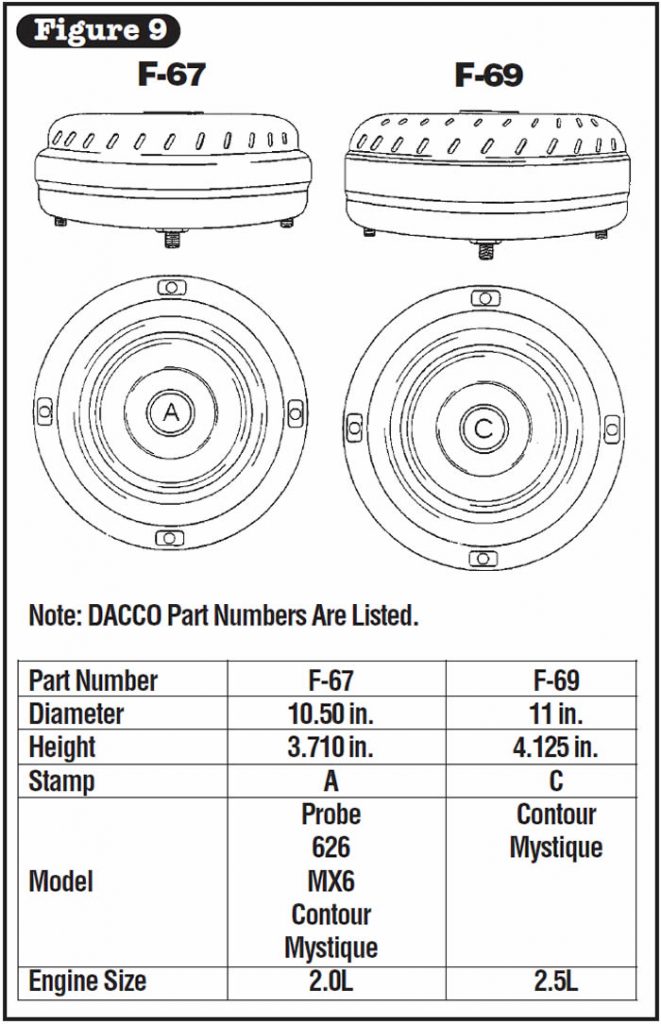

(5) Remove the transaxle if necessary, and ensure that the proper torque converter for the vehicle has been installed. See Figure 9 for proper converter identification.

Vehicles Affected:

All vehicles equipped with Grade Logic Control System.

When road testing the vehicle on the lift the transmission will exhibit wrong-gear starts and the transmission shuttle shifts 2-3-2 or 3-4-3.

When the solenoid command is checked, the commands match the above operation of the transmission.

Honda/Acura vehicles that are equipped with Grade Logic Control System use the PCM to control shifting while the vehicle is ascending or descending a hill or reducing vehicle speed.

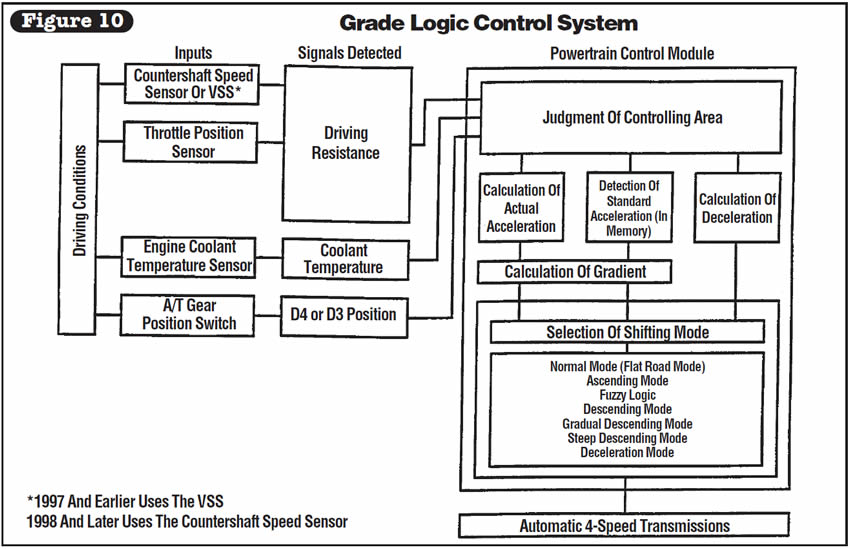

The PCM uses what is called a Fuzzy Logic System that compares actual driving conditions with memorized driving conditions based on inputs from several sensors, which is illustrated in Figure 10.

Note:

- 1997 and earlier vehicles with grade logic use the Vehicle Speed Sensor for speed-signal input.

- 1998 and later vehicles with grade logic use the Countershaft Speed Sensor for speed-signal input.

The Grade Logic Control System commands three modes of strategy as follows:

Ascending Control

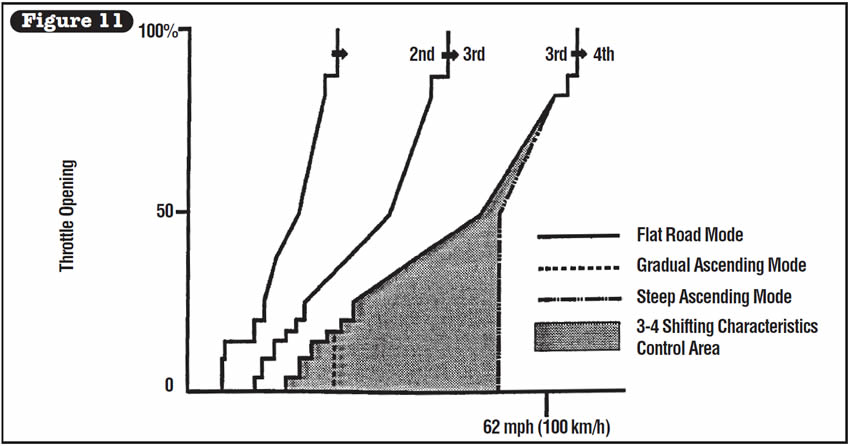

When the PCM determines that the vehicle is climbing a hill in the D4 or D3 gearshift position, the system extends the 2-3 and 3-4 shifts to prevent the transmission from making frequent shifts between 2nd and 3rd gears and 3rd and 4th gears, in order to provide more power when needed.

Shift schedules stored in the PCM enable the PCM Fuzzy Logic to select automatically the most-suitable gear according to the steepness of the hill, which is illustrated in the graph in Figure 11.

Descending Control

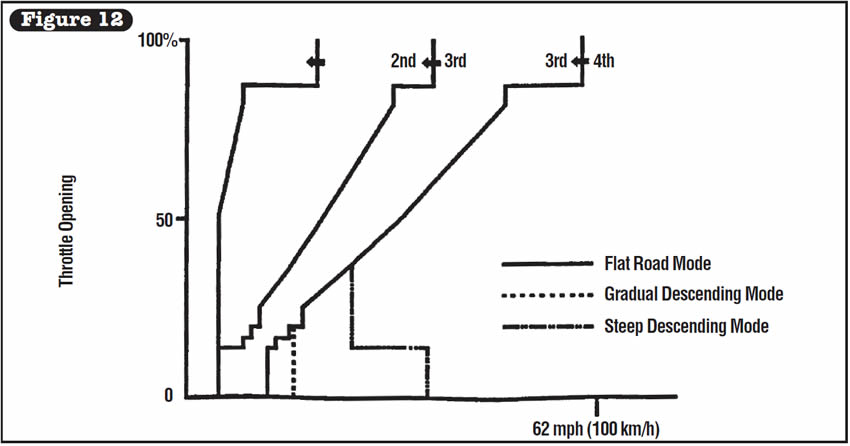

When the PCM determines that the vehicle is going down a hill in the D4 or D3 gearshift position, the upshift speed from 2nd to 3rd gear or 3rd to 4th gear, when the throttle is closed, becomes faster than the set speed for flat road driving to prolong 3rd and 2nd gears.

This, in combination with engine braking, achieves smooth driving when the vehicle is descending a hill. There are two descending phases with different 3rd gear and 2nd gear operating ranges according to gradient angle stored in the PCM.

When the vehicle is in 4th gear and you are decelerating when you are applying the brakes on a steep hill, the transmission will downshift to 3rd gear.

When you accelerate, the transmission then will return to a higher gear as illustrated in the graph in Figure 12.

Deceleration Control

When the vehicle goes around a corner and needs to decelerate first and then accelerate, the PCM sets the data for deceleration control to reduce the number of times the transmission will shift.

When the vehicle is decelerating from speeds above 27 mph (43 km/h), the PCM shifts the transmission from 4th to 2nd earlier than normal to cope with upcoming acceleration.

Warning: Do Not Perform The Final Road Test On A Lift. Do It On The Road!

June 2000 Issue

Volume 17, No. 6

- Chrysler A518 (46RH) and 46RE: Broken Front Planetary Carrier

- Saturn: Erratic Shift Pattern After Rebuild or After Reprogramming PCM

- Ford/Mazda CD4E/LA4A-EL: Continuous Front-Seal Leak or Seal Blowout

- Honda/Acura: Grade Logic Control