Up to Standards

Author: Mike Weinberg, Contributing Editor

Subject Matter: Immediate and root causes

Issues: Transfer-case problems

One of the keys to being successful in any repair is to do a thorough root-cause failure analysis on every unit you work on. Many seemingly unexplainable failures occur due to problems that are outside of the area you are looking at. By now every tech should know that components outside of the unit can create a failure. Failures recurring inside the unit mean that the part or parts that failed were influenced by other parts that were missed during the teardown and inspection of the unit. These are expensive mistakes as a problem that comes back under warranty is on the shop and undermines your customer’s faith in the organization. The examples we will look at in this article will highlight the importance of a careful total vehicle inspection before providing the customer an estimate. Once the customer hears what they believe to be the final number, that number becomes carved in stone, and it’s almost impossible to overcome if there are additional parts or labor required.

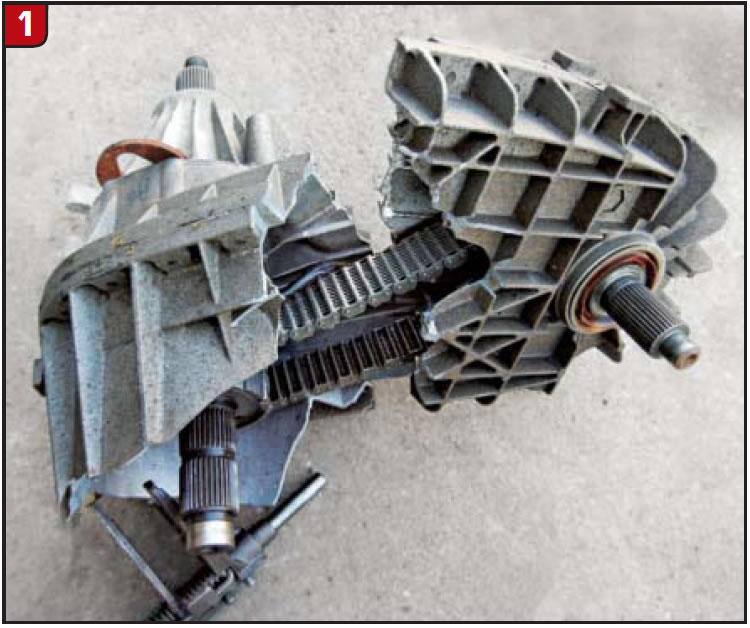

The Magna Powertrain 271/273 transfer case will often show up in a shop completely destroyed, actually cut in half. These are big heavy transfer cases found in Ford and Dodge pickups. As you can see (Figure 1), this is a terminally fatal destruction of the transfer case with no rebuildable core. How did this happen? On Ford units from 1999 and up look at the front drive shaft. These are big heavy units with a correspondingly stout driveshaft which is equipped with a double Cardan U joint. The double Cardan joint was the forerunner of the modern CV joint, with a housing that has two U joints, with a centering pin and ball between the two joints. The centering pin and ball can break, allowing the drive shaft to reach angles that were never intended and the front drive shaft destroys the case.

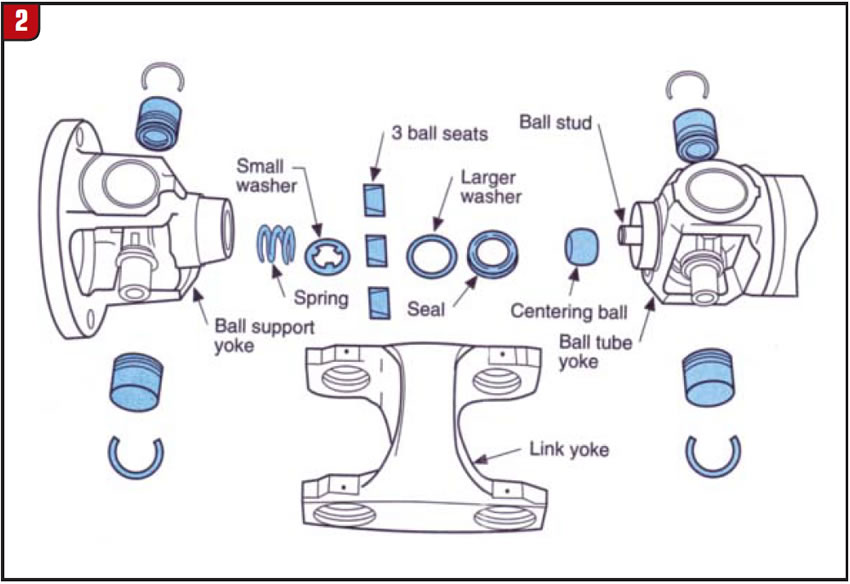

Commonly on Fords, which have manual locking front hubs or vacuum-controlled front locking hubs, a problem with one of the hubs not releasing for 2WD will damage the front drive shaft. To make matters worse, the double Cardan joint in this application does not have Zerk fittings to lubricate the assembly. The problem here is compounded by the fact that with this kind of damage it is impossible to test drive the vehicle, where a vibration in the front shaft would be a dead giveaway that the joint has to be replaced. If you simply replace the transfer case, it will fail again without a proper fix for the front prop shaft. Figure 2 is a parts blowup of the double Cardan joint.

The same kind of damage is common in Dodge vehicles due to the same issue with the front shaft. On Dodge vehicles the front driveshaft is a “live” shaft, which means there is no disconnect for 2WD and the shaft is spinning all the time, which mimics the Ford problem with front locking hubs that do not release. The cure here is to ALWAYS inspect the front shaft for excess travel or play in the double Cardan joint and replace same if needed. No driveline vibration can be tolerated without catastrophic failure happening. Make sure that the shaft is checked before speaking with the customer regarding cost so that you don’t pay for it.

On 2004 and up Dodge units, you may see a leak between the transmission and the transfer case. Usually when this comes to your attention the T-case was run dry and the parts have experienced a nuclear melt down. How did this happen? On Dodge trucks there is no gasket between the transmission and transfer case, as both units are completely sealed. Without a gasket, saltwater can get between the cases and will eat holes in the T-case. This can happen because a customer has driven the vehicle down a boat ramp to put a boat in the water.

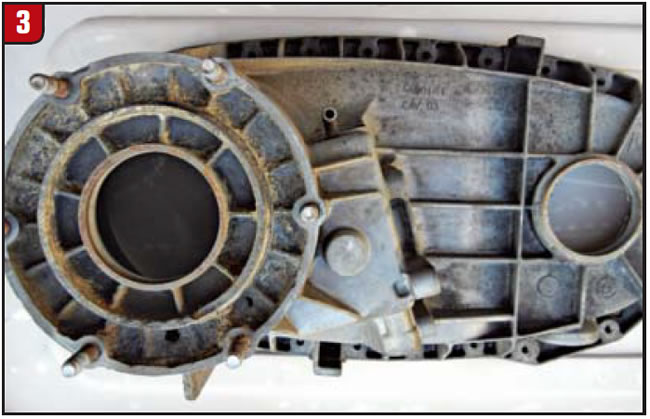

Another cause is the road salt used to make roads driveable in winter weather. The T-case sits behind the cross member, and with huge wheel wells on the body, a lot of salt spray gets tossed around under the chassis, infiltrating the space between the transmission and T-case. Salt corrosion ate holes right through the T-case where it joins the transmission (Figure 3). The cure here is always use RTV between the transmission and T-case to seal out any water intrusion.

All transfer cases that use a range fork will exhibit repeat failures of the range fork. The unit will be torn down, the range fork is discovered to be worn out, and a new fork is installed. However, 2,000 miles later the truck is back in the shop with another ruined range fork. How did this happen?

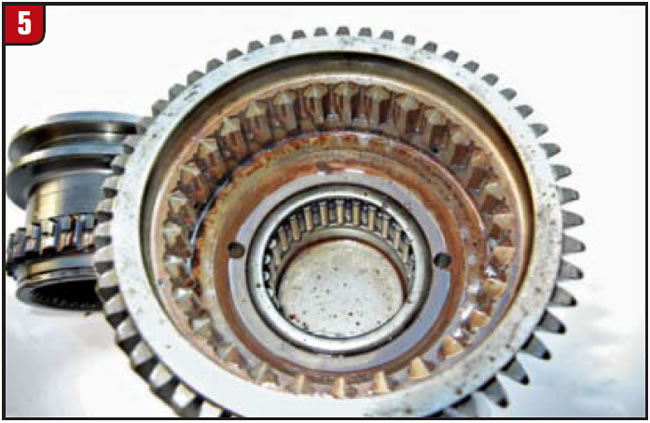

The range fork will have no lateral load on it according to the design. However, it is common for the engagement teeth inside the input and outside the range sliding sleeve to wear out and get a taper. This taper causes lateral movement in the sliding range sleeve and side loads the range fork, which fails very quickly due to the side load it was not engineered to handle.

Figures 4 and 5 show the damage on the engagement teeth of the input and sliding range sleeve. The range-fork failure was a byproduct of a failed input shaft and sliding range sleeve, which is easy to overlook. Make sure you carefully examine every part of the unit to prevent repeat failures because something was overlooked on the teardown. There are no unnecessary parts in a vehicle. They are all there to create a smooth operating blend of complex systems. The old saying “look before you leap” is still around because it is true.

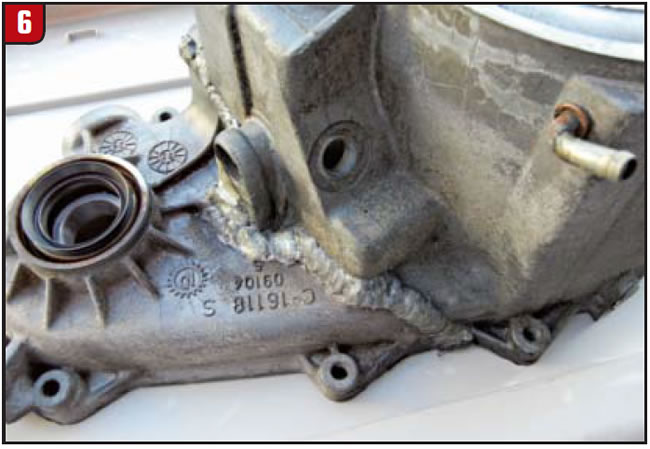

Figure 6 shows a weld done on a 231 transfer case. The case was cracked from the bottom edge right through the selector shaft. This core came in completely covered with dirt, and the weld was not visible. The unit worked perfectly and did not leak. In the cleaning process, the weld was discovered.

We would not reuse the case even though the weld was a thing of beauty and done by an artist. How did this happen? There are several conditions that will cause this kind of a crack in a Jeep Wrangler with a 231 T-case. The first is a frozen slip yoke or seized spline on the front drive shaft. When the drive shaft can no longer move in and out during changes in the suspension, something has to give, and it will be the case. The second principal cause is over travel of the suspension due to airborne off road fun, or speed bumps, parking lot curbs, etc. Anything that bottoms the front shaft beyond its travel design will crack the case. If your customer wants to go to Baja or likes to hit speed bumps at high speed, this kind of damage will occur.

Figuring how it broke and preventing a reoccurrence is a win-win for any shop. You didn’t sign up to be a CSI, but it comes with the territory.

Mike Weinberg is president of Rockland Standard Gear.