Up To Standards

- Author: Mike Weinberg, Contributing Editor

ZF Industries is one of the world’s largest and most-advanced powertrain manufacturers. For many years the company has been producing automatic and manual transmissions for a variety of the global automakers. ZF designs and manufactures automatic transmissions that are arguably the best-performing units on the market. It has been at the forefront of manual-gearbox technology with product in light-, medium- and heavy-duty applications.

In 1988 ZF designed and produced the S6-40 6-speed transmission used by General Motors in the Chevrolet Corvette C4 and achieved a large share of the market for full-sized pickups when Ford began to use the S5-42 5-speed unit.

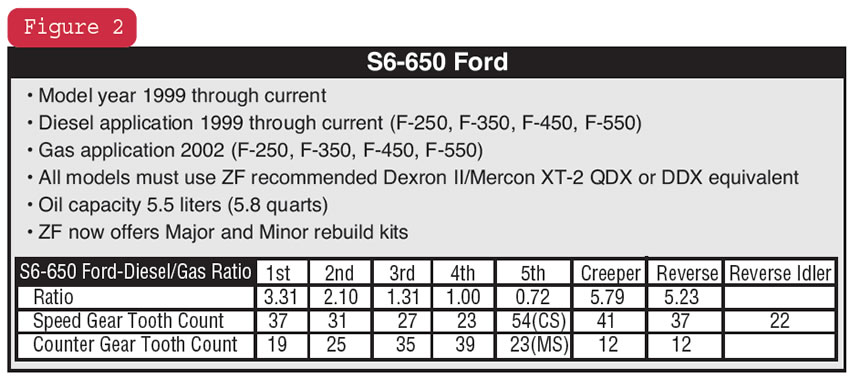

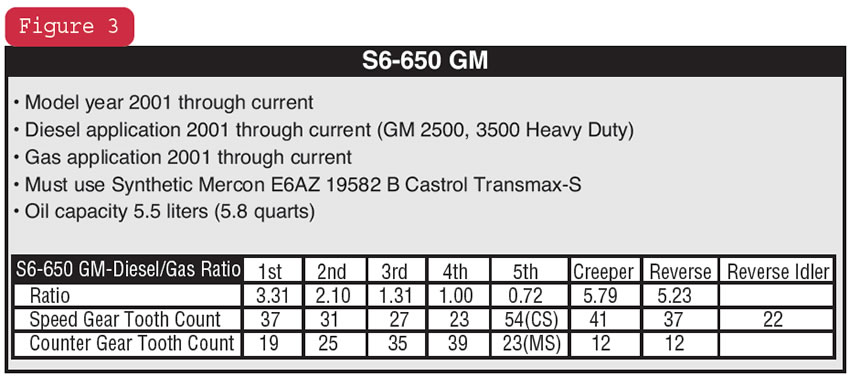

The present trend toward larger and heavier-duty pickups has now brought the ZF S6-650 6-speed manual gearbox onto the scene. This 6-speed transmission was introduced in 1999 in the Ford F 250, F 350, F 450, F 550 and stripped-chassis models. It has been used behind diesel engines from 1999 to current production and behind gasoline engines starting in 2002 models. GM adopted the S6-650 transmission for use in its 2500 and 3500 heavy-duty pickups behind both gas and diesel engines in the 2001 model year.

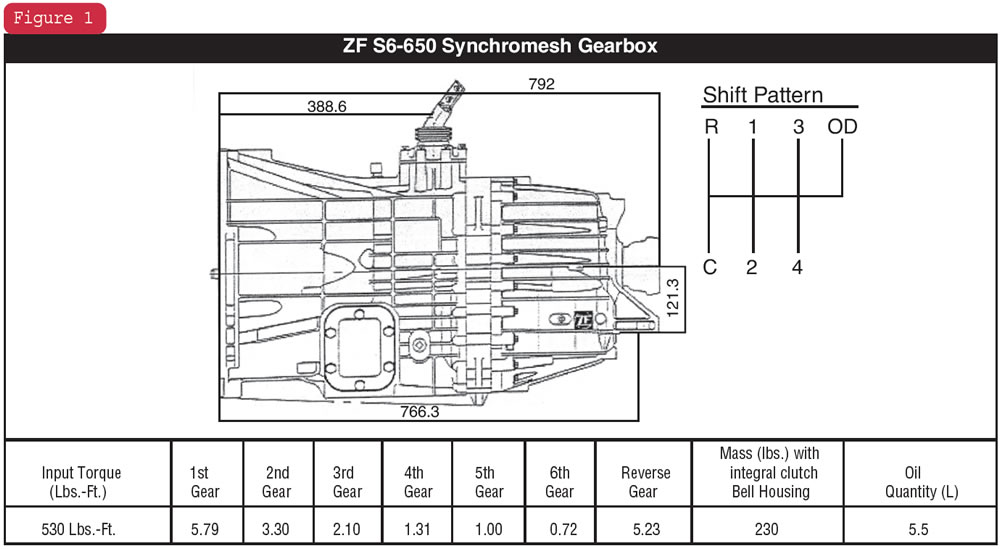

The S6-650 weighs a hefty 230 pounds and can handle 530 lb.-ft. of torque in vehicles with a GVW of 26,000 pounds (13 tons). This unit uses 5.8 quarts of synthetic Mercon ATF, Ford part #E6AZ-19582-B or Castrol TransMax-S. Using only the specified fluid is critical for proper shifting and durability. The S6-650 trans is equipped with an internal lubricant pump, which is driven by the countershaft and pumps pressurized lube through an oil cooler in the radiator identical to those found in automatic units (see Figure 1). This is another reason not to use anything but the specified lubricant.

This gearbox is equipped with power-take-off access and on some models uses a parking brake attached to the extension housing. You can see in the gear-ratio chart provided here that the S6-650 is equipped with a “creeper”-low ratio of 5.79-1 for added pulling power. Fifth gear is overdriven with a ratio of 0.72-1 for added fuel economy (see Figure 2). The gear ratios are the same for both Ford and GM models (see Figure 3).

The S6-650 has been in service in Ford models since 1999 and has a long-enough history to establish certain failure patterns and their causes. Understanding the root cause of failures is the key to proper diagnosis and to taking preventive steps to prevent repeat failures under your warranty and to become aware of the external issues in the vehicle that can cause the type of damage you see on the original failure.

Cracked or Broken Bellhousings

Possible causes:

- Drivetrain vibration

- Out-of-balance parking brake

- Damaged dual-mass flywheel

- Damaged rear differential

- Vehicle modification – shortened or lengthened driveshaft

- Bent or out-of-balance driveshaft

Corrective Actions to Be Taken

Check the backlash on the dual-mass flywheel. The backlash between the primary and secondary plates should be no more than 3⁄4 inch.

Non-factory driveshafts should be checked for size and diameter. Shafts up to 51 inches long can use 3-inch-diameter tube. Driveshafts between 51 and 55 inches long must use 3.5-inch-diameter tube, and driveshafts between 55 and 59 inches long must use 4-inch-diameter tube. Correct U-joint working angles are greater than 0.5° but less than 3°. Driveshafts must be balanced at 3,000 rpm to within 0.4 inch-ounce at the ends and within 0.8 inch-ounce at the center support.

Anytime you encounter a unit with a cracked or broken bellhousing, you must do more than replace a case to cure the problem. The cause of the failure will not be in the unit but an external source related to the driveline as listed. Do your homework and avoid expensive repeat failures.

Reverse-Gear Clash and Jump-out

Reverse gear is synchronized. Many drivers will shift to reverse before the vehicle comes to a complete stop. Teach the driver to wait until the truck comes to a complete stop before shifting into reverse. This type of failure should be considered driver abuse and outside the warranty coverage.

Notchy Shifting

The S6-650 is a heavy-duty unit with a lot of geartrain in mesh. This is a truck transmission that will shift more slowly than a smaller-car transmission because of the greater inertia present in the clutch and transmission design. Some notchy feel to the shifts is normal, particularly in 3rd gear. If the clutch is worn or out of adjustment for very long, it will create excessively notchy shifts that will require replacement of the synchronizers and rings.

Gear Rattle in Neutral

The complaint is usually a gear rattle occurring at idle in neutral. This single complaint results in more wasted labor by repair shops than any other complaint. Do not remove the unit until you make the following simple test: With the transmission in neutral and the clutch engaged slowly, raise the idle speed to 2,500 rpm. If the noise floats out at or above 1,500 rpm, the noise is not in the gearbox. Nothing you do – including replacement of all the gears – will correct this problem, because it is external to the transmission. The cause is harmonic vibrations causing the geartrain to rattle inside the unit. The main source of the vibrations is a worn or defective dual-mass flywheel, or a worn or damaged damper assembly on the clutch disc. A secondary cause on diesel engines may be a worn or out-of-time injector pump. If the noise stops with increased engine speed, it is not internal to the transmission.

Catastrophic Gear Damage After Overhaul

This unit is equipped with a gerotor lube pump in the front of the transmission case, driven by the countershaft. The pressure side of the lube circuit is equipped with a pressure-relief valve that consists of a spring-loaded checkball retained in the case by a spring-steel star washer. This valve vents excess pump pressure back into the case, as is common with automatic transmissions. During overhaul it is common for shops to remove the pressure-relief valve in an attempt to do a thorough job cleaning the case. When you re-install the pressure-relief valve, it is extremely important to make sure that the star-shaped washer is seated correctly in the case. Under pump pressure it is common for the star washer to blow out, leaving the spring, checkball and washer free to get trapped between the moving gears, which becomes a major-league expensive comeback. My advice is not to remove the pressure-relief valve unless the case is heavily contaminated with metallic debris.

5th-Gear Shift Problems

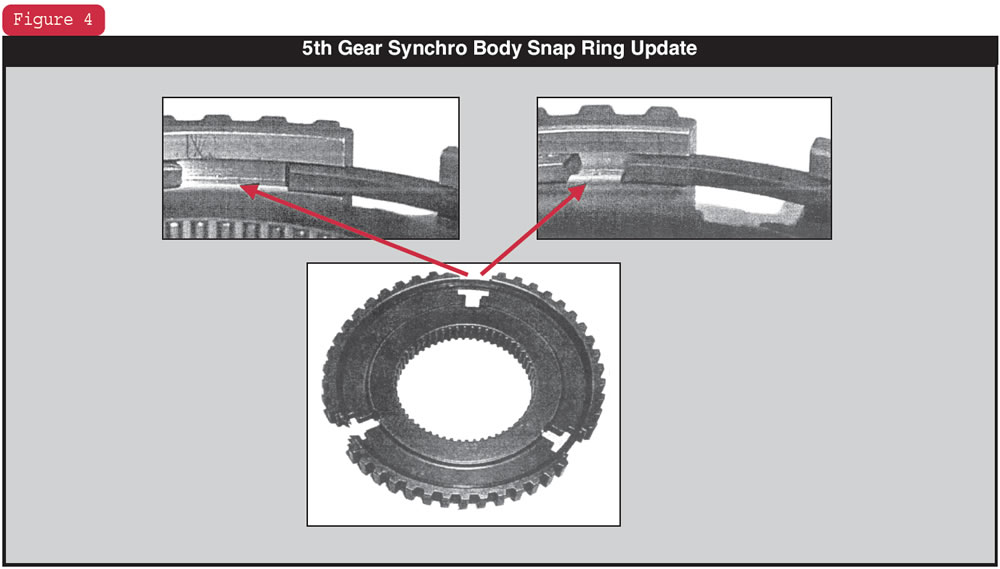

The 5th-gear synchronizer hub on this unit is equipped with a snap ring to retain the pressure pieces (synchro keys) in position during shifts (see Figure 4). The first-design snap ring was produced with a gap that was too large. Occasionally the snap ring will rotate in the synchronizer hub during use and the gap will line up with the opening for the synchro key. When this happens, the key will move through the gap in the retaining ring and either fall out or jam the synchronizer. A redesigned synchro hub now available has a longer retaining ring, which prevents the key from moving through the gap. On all internal repairs, compare the 5th-gear synchro retaining snap ring to the pictures shown here. If your ring has the wide opening, replace it with the later design.

The S6-650 is in essence a medium-duty-truck transmission weighing 230 pounds. It is important from a safety standpoint to make sure it is properly secured to a heavy-duty transmission jack during any R&R procedure. You also will need an engine hoist or some other type of lift to remove the geartrain from the transmission case. The Ford service manual will give you the proper teardown and assembly details and a list of essential tools required to repair this unit successfully.