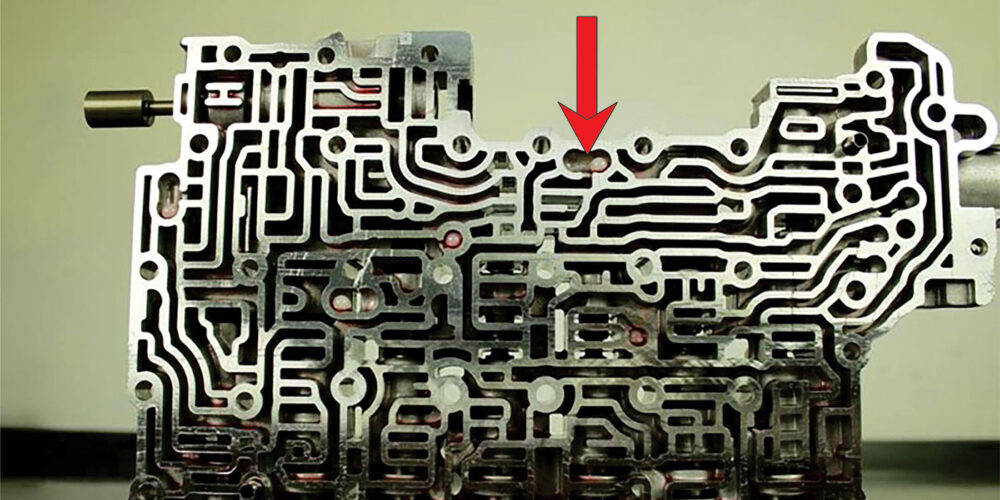

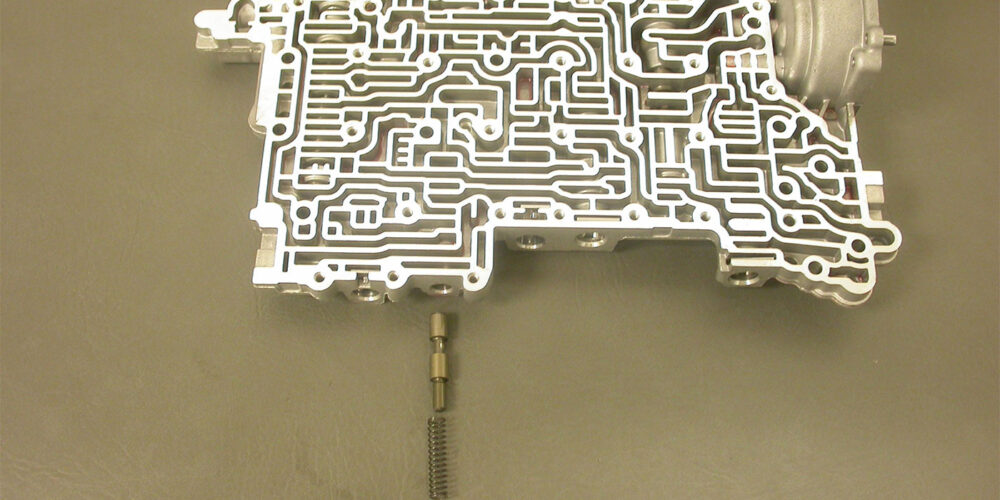

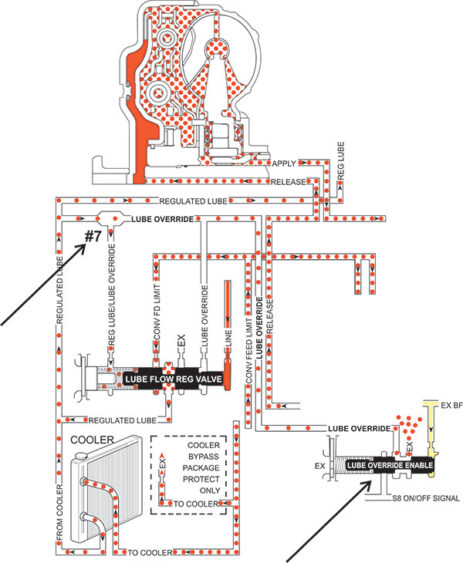

Beginning in October of 2015, GM removed the #7 Check-ball from the solenoid valve control body in the 8L90 transmission (see Figure 1). This was done in conjunction with the elimination of the Lube Override Enable Valve from the upper valve body as shown in Figure 2.

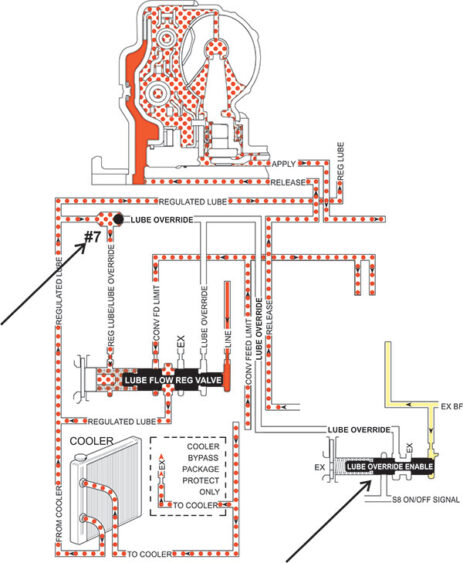

When this took place, the Lube Override Enable Valve bore was cast shut as well as the channels feeding the valve. No modification was made to the spacer plate. This #7 shuttle ball seats against the Lube Override passage while the transmission is operating in Park, Reverse, Neutral and Drive ranges. With the #7 ball in this position, Regulated Lube fluid enters the Regulated Lube/Lube Override circuit to hold the Lube Flow Regulator Valve in the regulating position (see Figure 3).

When the transmission enters a high-speed default gear, Lube Override pressure is routed to both the #7 ball and the Lube Flow Regulator Valve to ensure Converter Feed Limit pressure enters the Regulated Lube circuit.

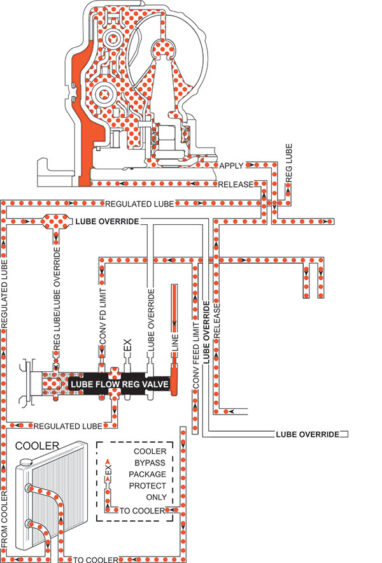

By removing the #7 ball along with casting shut the Lube Override Enable Valve bore, the Lube Override circuit has been eliminated entirely. It no longer has any influence on the Lube Flow Regulator Valve (as seen in Figure 4).

Since this took place in 2015, many rebuilders have become accustomed to building later units not using this ball, especially since the spacer plate didn’t change in the area over this ball. So, when an earlier transmission comes into the shop to be rebuilt, leaving the #7 ball out is an easy oversight to make.

When this happens, Regulated Lube pressure will drop as it flows into the Lube Override circuit and exhaust out at the Lube Override Enable valve, as Figure 5 illustrates below. This also robs lube pressure going to the transmission which can cause a catastrophic failure.

What saved the day for one sharp tech when this happened recently was that he noticed that transmission temperatures increased rapidly on a road test getting higher than normal. When he returned to the shop, he pulled the cooler return line to check the flow and it was good. This put them back into the transmission to examine the cooler return circuit through the valve body. This is when they discovered that their unit needed the #7 ball. The overheat saved the day!

Read more stories from our Technically Speaking column series here.