Technically Speaking

- Author: Wayne Colonna, Technical Editor

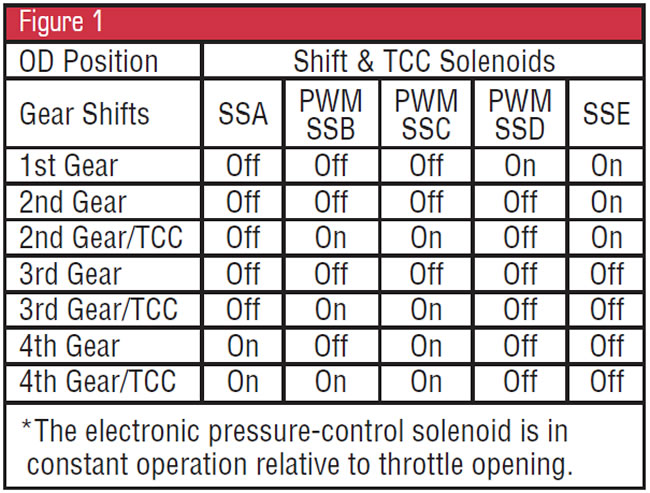

The 4F27E transmission uses two on/off solenoids and three PWM solenoids to produce each of the shifts and converter-clutch apply, as the chart in Figure 1 shows. The EPC solenoid is used to control line pressure relative to engine torque. So far this sounds easy, but from a strategy standpoint, it progressively moves toward a “different way of doing things” when compared with what we are accustomed to.

Let’s start off on familiar ground. Shift solenoids A & B are the on/off solenoids that, when they are off, block fluid from stroking valves. The pulse-width-modulated solenoids, C, D & E, are the opposite. When they are off they allow fluid to pass through the solenoid and stroke valves. OK, so far, not so bad. Sounds a little like the Chrysler 41TE/42LE transmissions with their normally applied and normally vented PWM and on/off solenoids.

The first departure from the “norm,” if you will, is that shift solenoid B could be better understood as a lockup/TCC solenoid. To call this shift solenoid B made it difficult for me when I first looked at a solenoid-application chart like the one in Figure 1. I kept thinking it was a gear-shift solenoid, not a TCC shift solenoid. But now, having clarified the operation of shift solenoid B, it would be good to do a “simple” overview of the function of each of the other “shift” solenoids. Doing so will make the solenoid-application chart considerably more understandable.

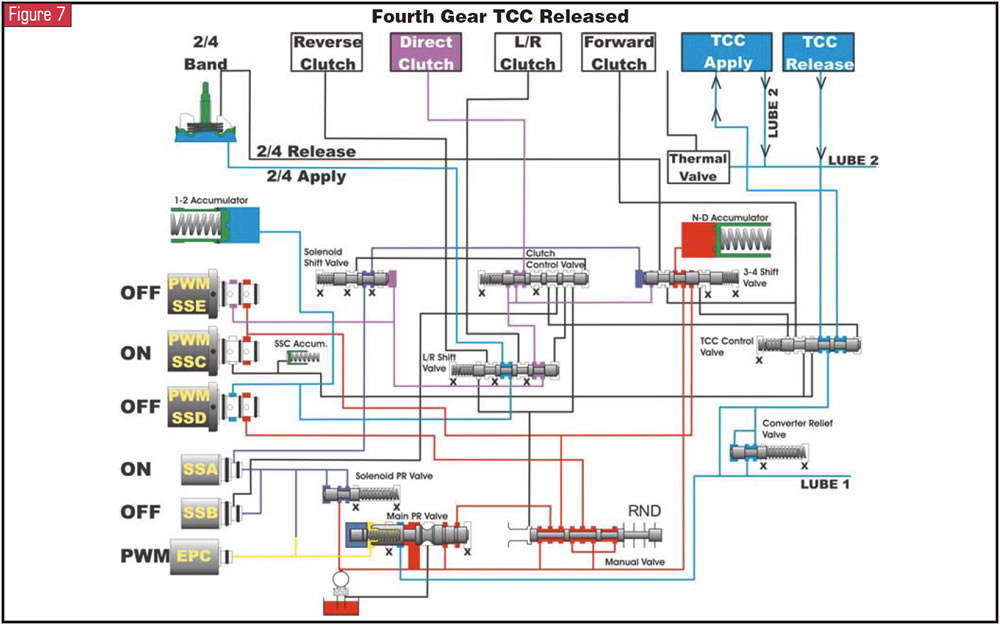

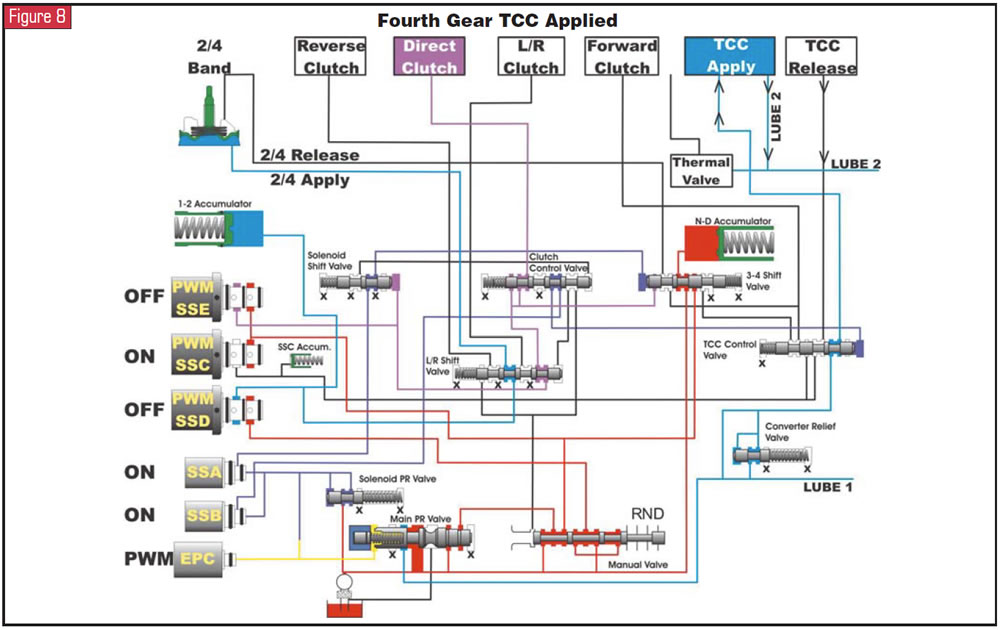

- SSA – When this solenoid is in the on position, it strokes the 3-4 shift valve, which exhausts forward-clutch and servo-release pressure.

- SSB – When this solenoid is in the on position, it strokes the TCC control valve, which exhausts the converter-release pressure, allowing for TCC apply.

- PWM SSC – When this solenoid is in the off position, it provides forward-clutch apply pressure.

- PWM SSD – When this solenoid is in the off position, it provides servo-apply pressure.

- PWM SSE – When this solenoid is in the off position, it provides servo-release pressure.

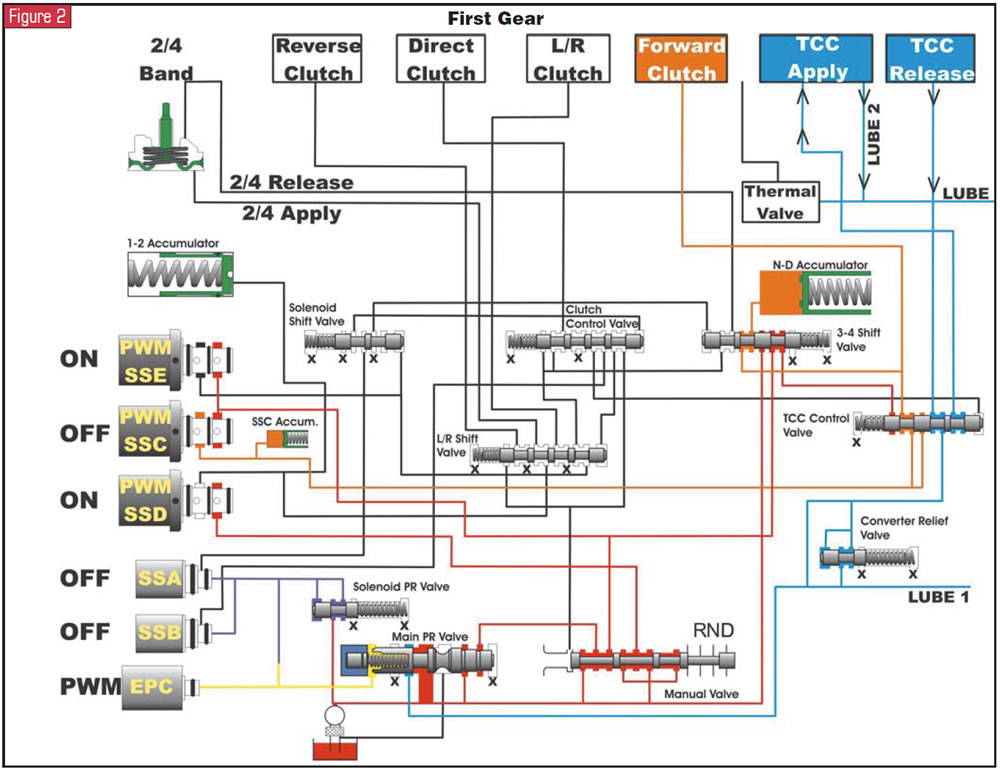

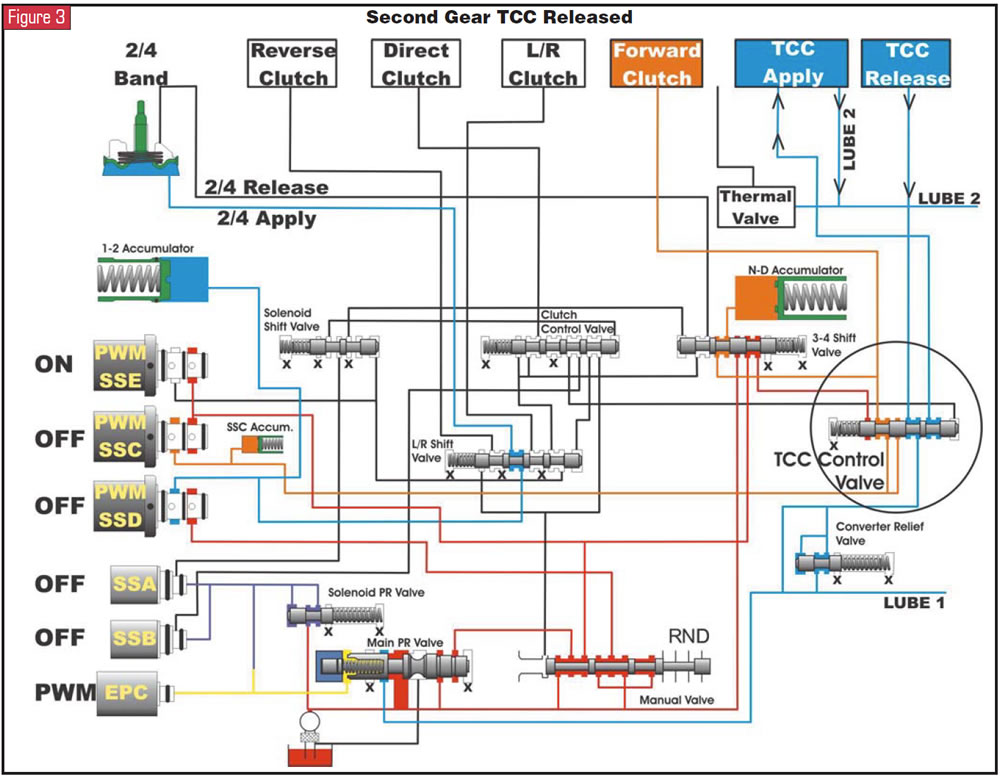

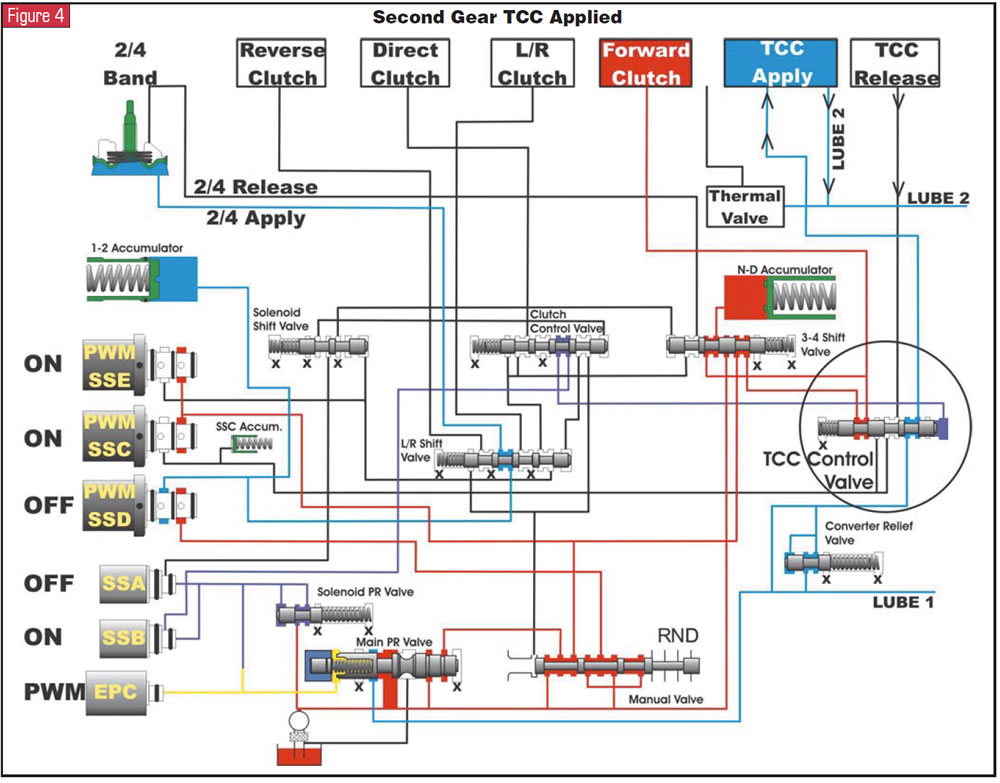

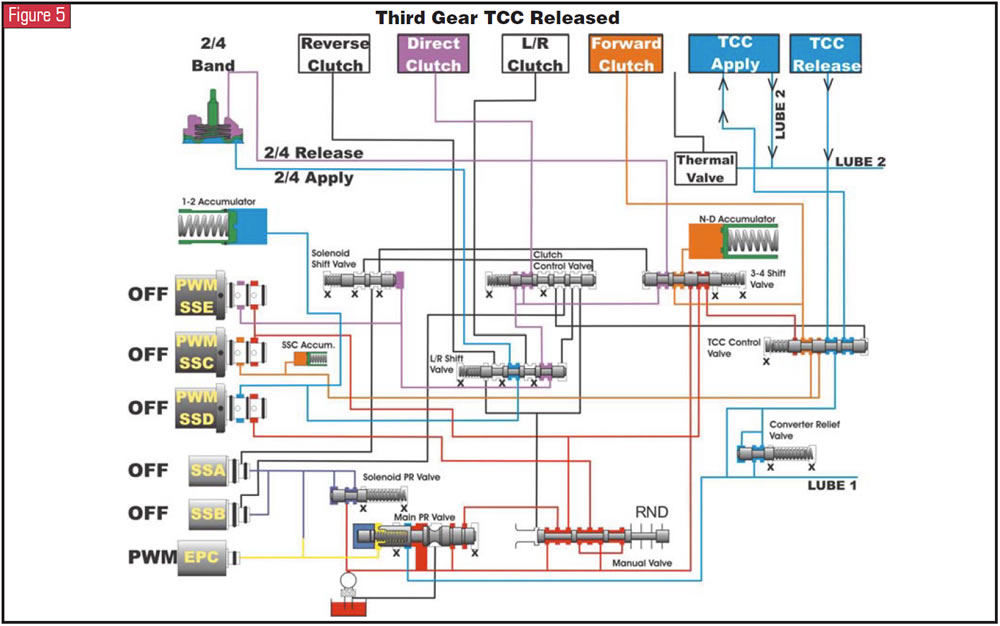

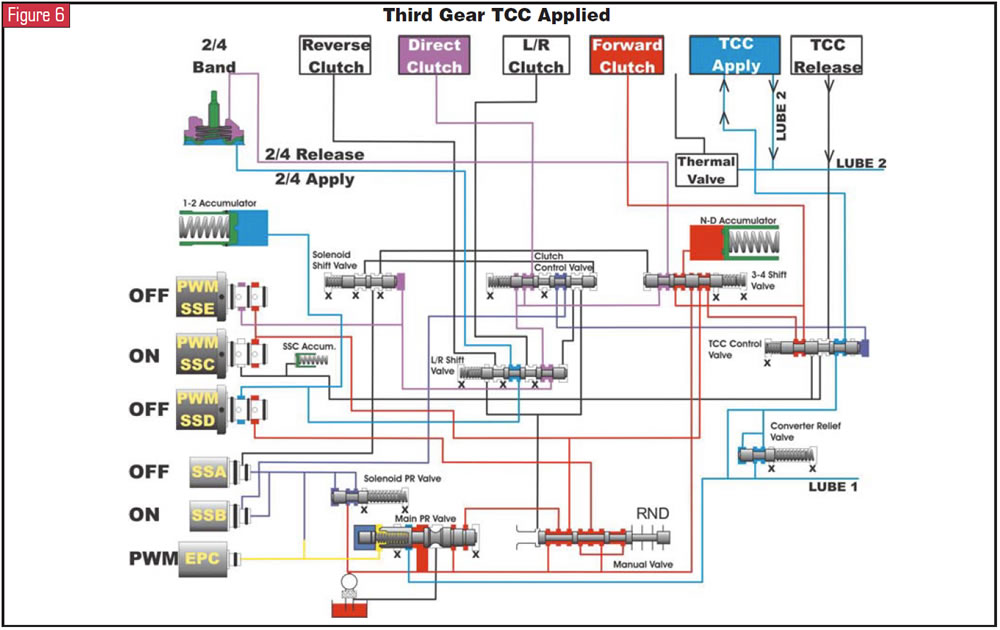

With this simple overview of the function of each of the shift solenoids, along with the hydraulics provided for each of the shifts while the manual valve is in the D4 position (figures 2-8), a closer look will provide a more-detailed understanding of “a different way of doing things.”

Using the second-gear TCC-off hydraulic provided in Figure 3, carefully look at the TCC control valve. Notice that forward-clutch oil runs through the valve from the PWM SSC to the forward clutch. Also notice that line pressure is routed to and blocked by the TCC control valve’s land next to the spring. When this TCC control valve is stroked by SSB for lockup, TCC-release oil becomes connected to the PWM SSC solenoid for a controlled TCC apply. At the same time, the forward-clutch apply oil switched from being fed by the PWM SSC solenoid to the line pressure that was being blocked by the land next to the spring (see Figure 4). Now that is a different way of doing things!

So the PWM SSC controls not only forward-clutch apply but also converter-clutch-apply feel. Should this solenoid malfunction mechanically, we could have a harsh apply or delayed apply into forward and no TCC, or a slipping-TCC concern. It is obvious that if SSB malfunctioned, we would experience TCC-apply issues as well. And looking at the TCC control valve, in theory should the valve or the valve bore develop excessive wear, combined with a lazy stroke of the valve, a forward-clutch slip could occur at the time TCC is being applied in second or third gear.