I recently read an article reported on the Global Newswire that finds the world’s transmission repair aftermarket is continuing to grow. In that article, the authors found that what was about $188 million global industry was expected to approach $235 million by 2028. There are certainly differences among the various nations in the units in for repairs but, for the majority, a transmission is a transmission be it a traditional step unit, a CVT, a DCT or even the units integrated into hybrid drivetrains.

With the globalization of automobile and light truck manufacturing and sales, the demand for parts, specialty rebuilding tools and equipment requires a world-spanning distribution of complex supply chains. This is the supply chain that is still in a recovery stage following the Covid-19 pandemic. As such, North American companies seek sales and distribution of their products on other continents. Conversely, manufacturers in Europe, Asia, Africa and Latin America seek U.S. representatives to make their products available state side.

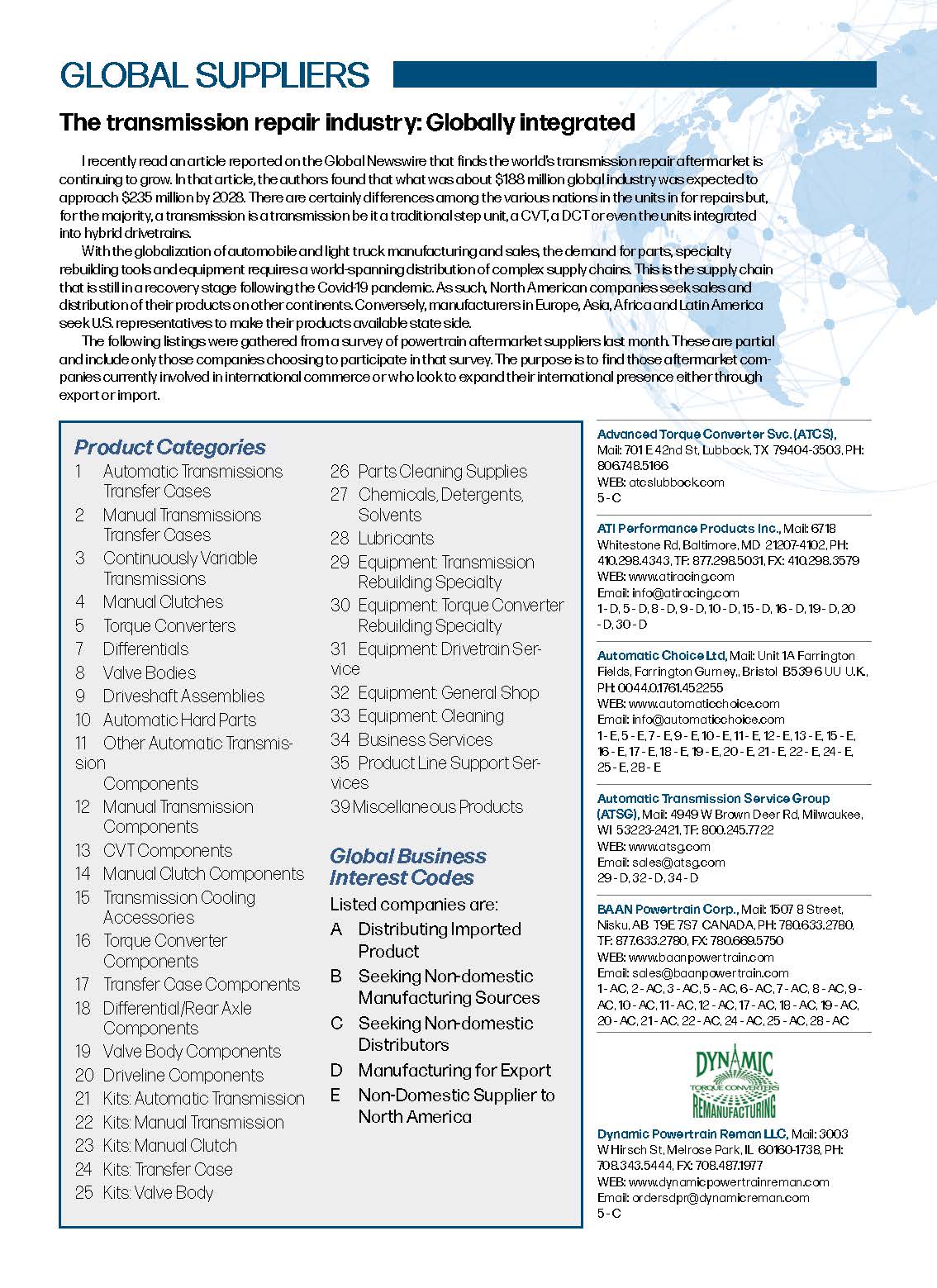

The following listings were gathered from a survey of powertrain aftermarket suppliers last month. These are partial and include only those companies choosing to participate in that survey. The purpose is to find those aftermarket com- panies currently involved in international commerce or who look to expand their international presence either through export or import.