Quality of the 1-2 and 2-3 shifts is poor; line pressure is within specs and the 1-2 accumulator assembly is correct for the vehicle application.

One cause may be that the transmission has a soft-shift 2nd-gear servo in it.

A common practice when the technician wishes to improve 1-2 and 2-3 shift quality without causing a harsh-shift complaint is to replace the original soft-shift second-gear-servo assembly with a firmer-shift servo assembly.

In some instances a Corvette servo has been installed, sometimes resulting in a 1-2 shift that is too firm, yet the other two servo assemblies that were available did not improve the 1-2 or 2-3 shift quality.

Now a fourth second-gear-servo assembly is available to service 4L70-E transmissions. It creates a 1-2 and 2-3 shift feel that is between those of the soft-shift servo and the Corvette servo.

This is possible because of the larger apply area created by the divider ring of the Corvette and 4L70-E servo assemblies. The smaller the hole in the divider ring, the greater the second-gear apply area. The firmer-shift servo assemblies also “clean up” the 2-3 shift because accumulation for the 2-3 shift takes place on the release side of the second-gear-servo assembly.

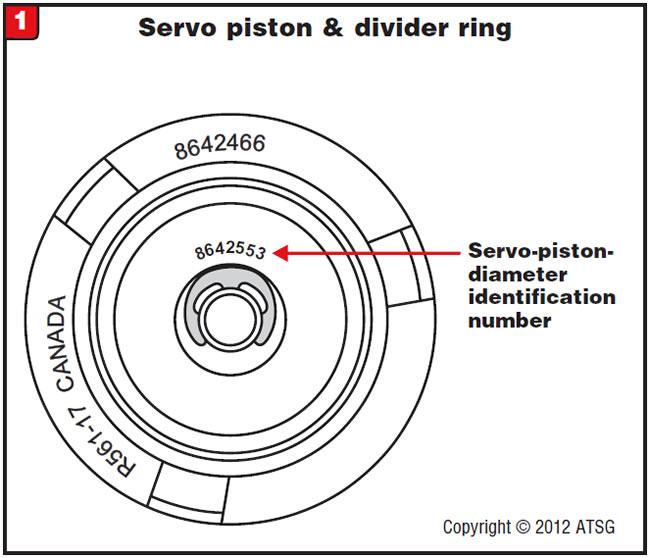

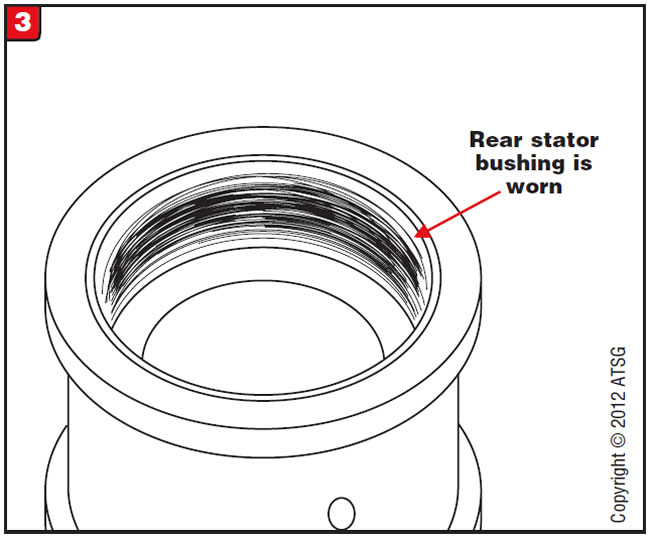

The soft-shift servo assemblies have casting numbers of 8642553 and 8642554 on the rear of the servo casting (Figure 1) and have divider-hole diameters of 2.312 inches and 2.520 inches, respectively. They typically are used in vehicles with V-6 engines or small V-8s.

The Corvette servo has a casting number of 8642093 and has a divider-hole diameter of 1.792 inches.

The 4L70-E servo has a casting number of 24229159 and has a divider-hole diameter of 2.075 inches. Figure 2 shows all four servo pistons and divider rings and their dimensions. Aftermarket firm-shift servo assemblies also are available.

- 4L70-E 2nd-gear servo piston . . . . . . . . . .24230441

- 4L70-E divider ring . . . . . . . . . . . . . . . . . . .24229157

The transmission makes a third-gear start even though first gear is commanded. It also may bind up in reverse and manual low. Inspection after disassembly reveals that the 3-4 clutch is badly burnt.

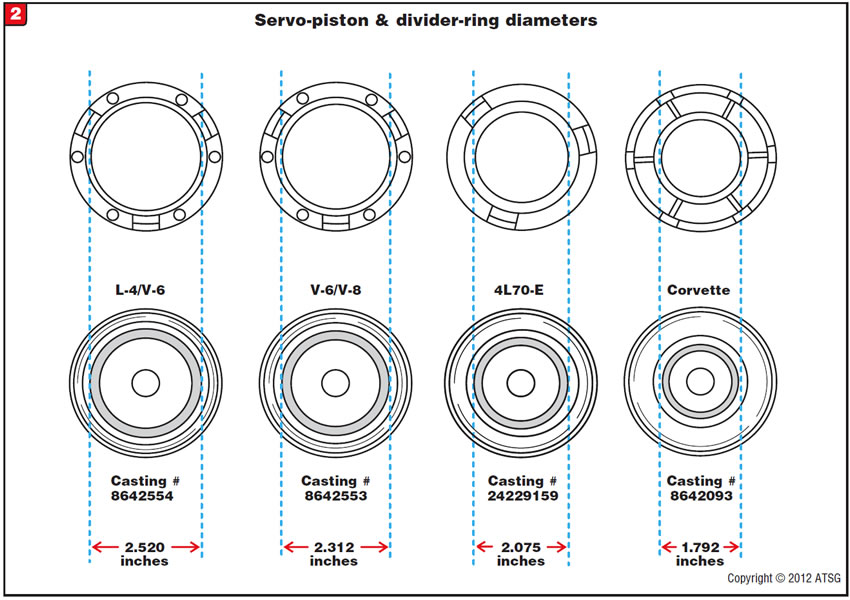

The rear stator bushing is worn (Figure 3).

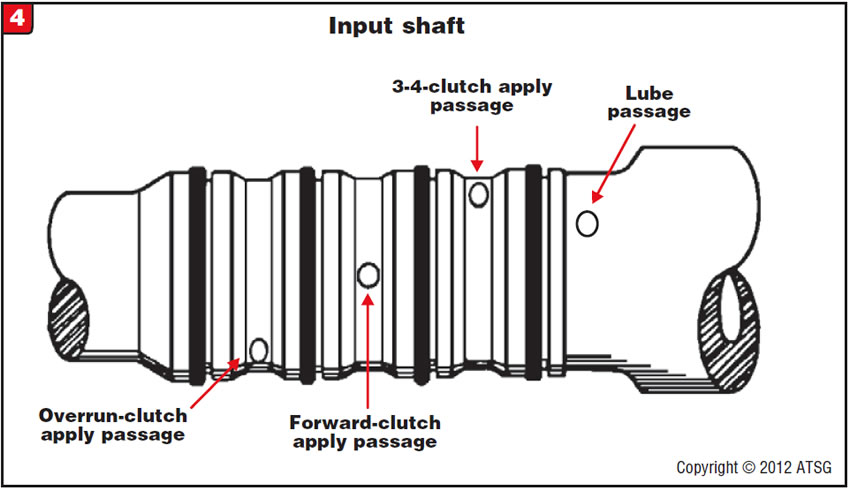

When the rear stator bushing wears, a cross feed takes place across the input-shaft sealing rings. The feed hole on the input shaft closest to the drum is the lube circuit; the lube-circuit oil will cross feed into the feed hole above it, which is the 3-4 clutch circuit (Figure 4). The continual flow of lube oil into the 3-4 clutch-feed circuit puts a drag on the clutch that not only burns it but causes a third-gear start.

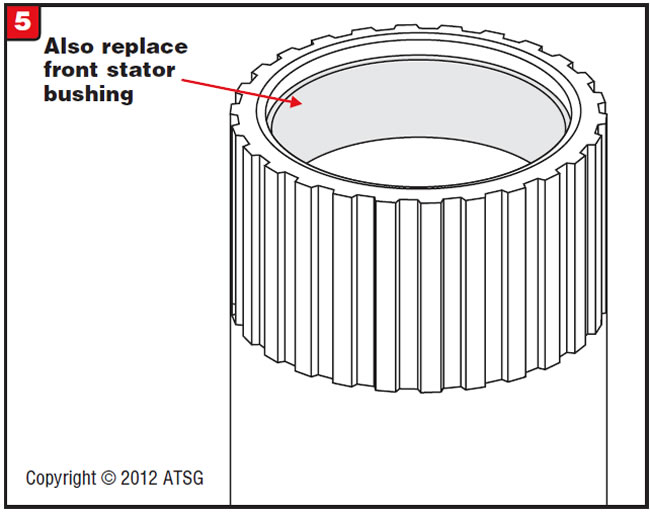

The bind in manual low results from the fact that when the low/reverse clutch is applied and lube oil causes the 3-4 clutch to be applied, a bind-up will occur and also will cause the bind in reverse. This condition gets worse as the transmission warms to normal operating temperature. It is a good idea to replace both the front and rear stator bushings (Figure 5), not only to prevent the complaint mentioned but also to ensure that the input shaft spins concentric to its related components.

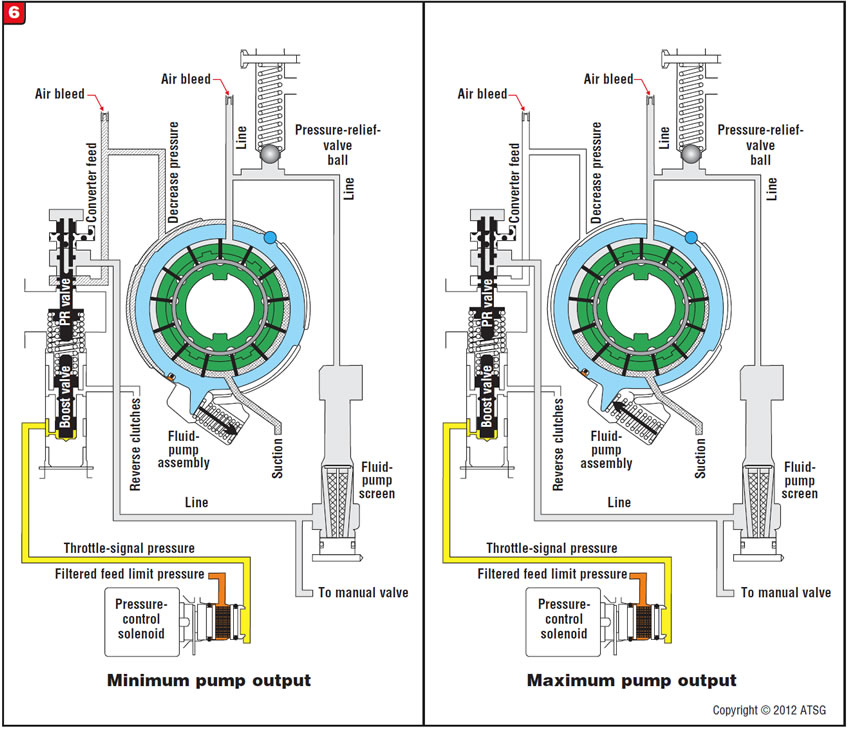

The transmission came in for repairs because of burnt frictions. After rebuild, it may be discovered that line pressure is unstable and worsens as it heats up. If line-pressure instability is not noticed during a road test, the transmission comes back with burnt frictions, similar to when it originally came in for repairs.

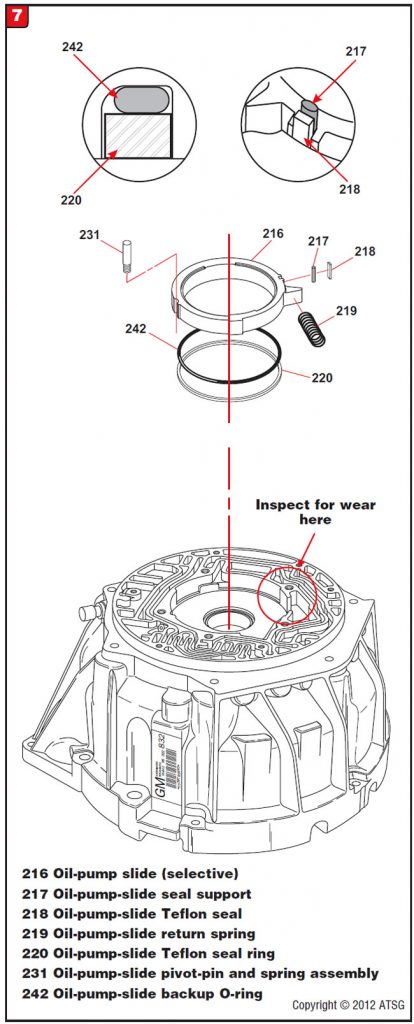

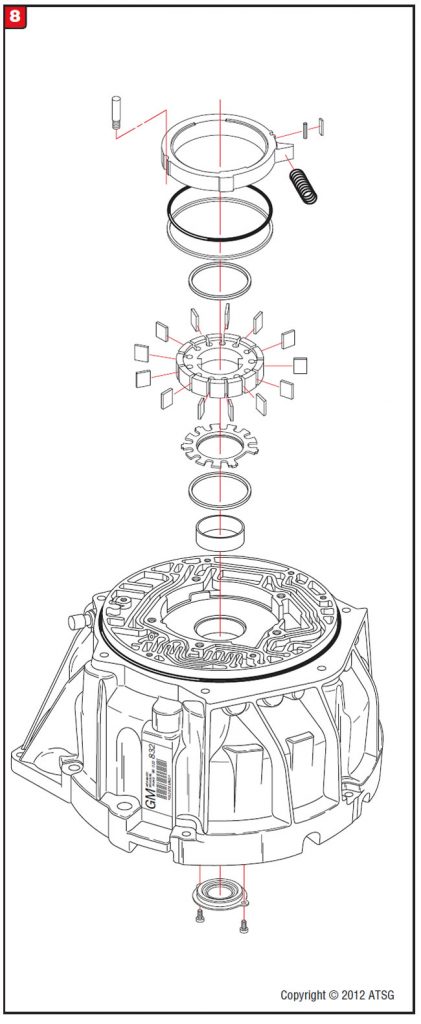

The cause may be a worn converter housing in the area of the pump-slide seal (Figure 7) where it seals decrease oil as the slide moves back and forth from high- to low-volume positions (Figure 6).

The rebuilder overlooks this area of the pump assembly when the decision is made not to remove the slide, rotor and vanes from the housing (Figure 8).

Replace the converter housing.

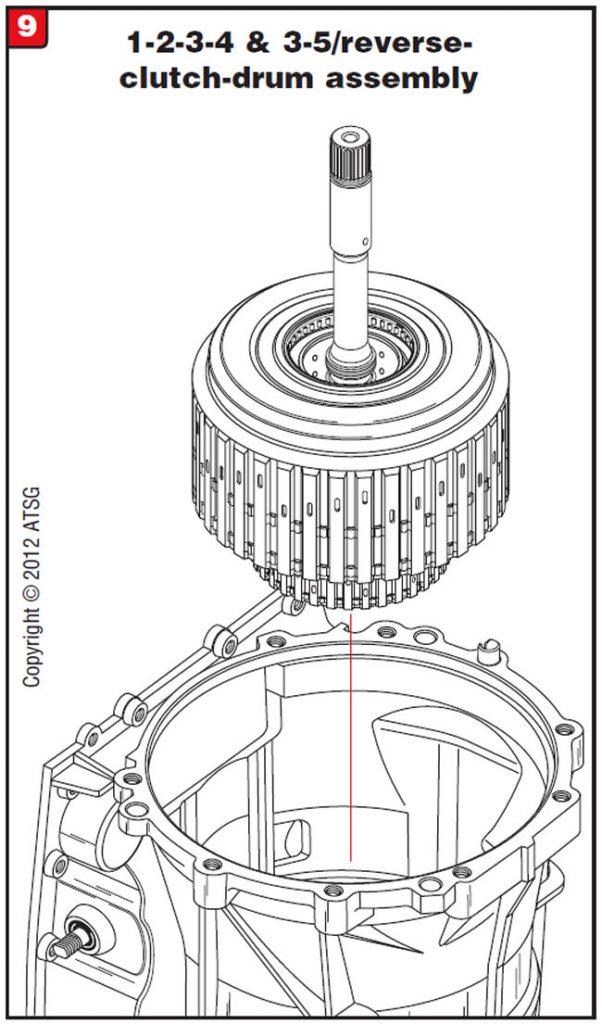

A complaint of a delayed reverse accompanied by a slipping reverse and a flared or slide 2-3 shift. The problem may be severe enough to produce solenoid-performance codes and put the vehicle into a failsafe condition.

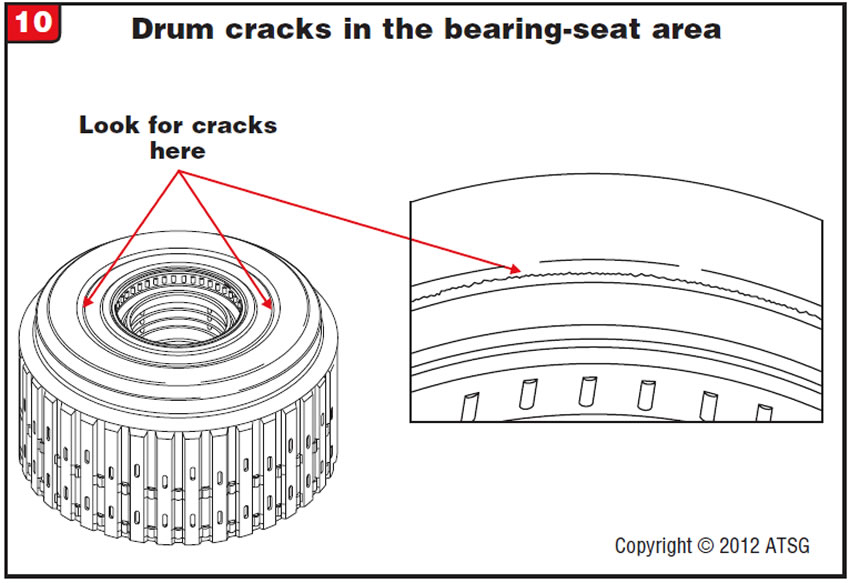

One cause may be that a crack developed in the 1-2-3-4 & 3-5/reverse-clutch drum (Figure 9) by the bearing seat where the drum sits against the pump (Figure 10).

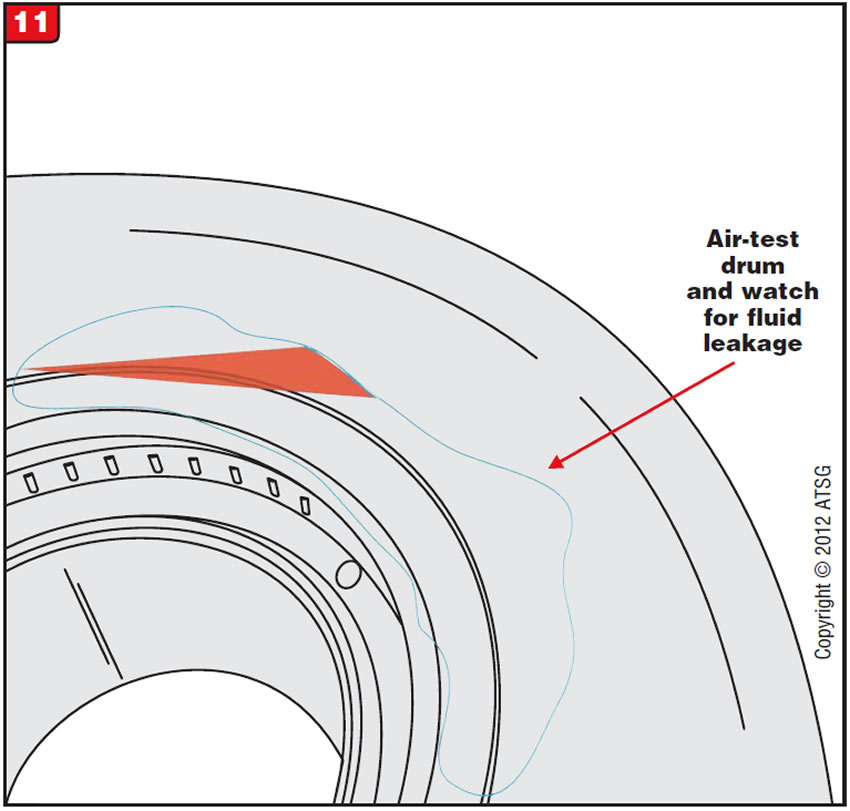

The size of the crack determines the severi-ty of the condition. Air-check the drum while observing the bearing-seat area for leakage (Figure 11).

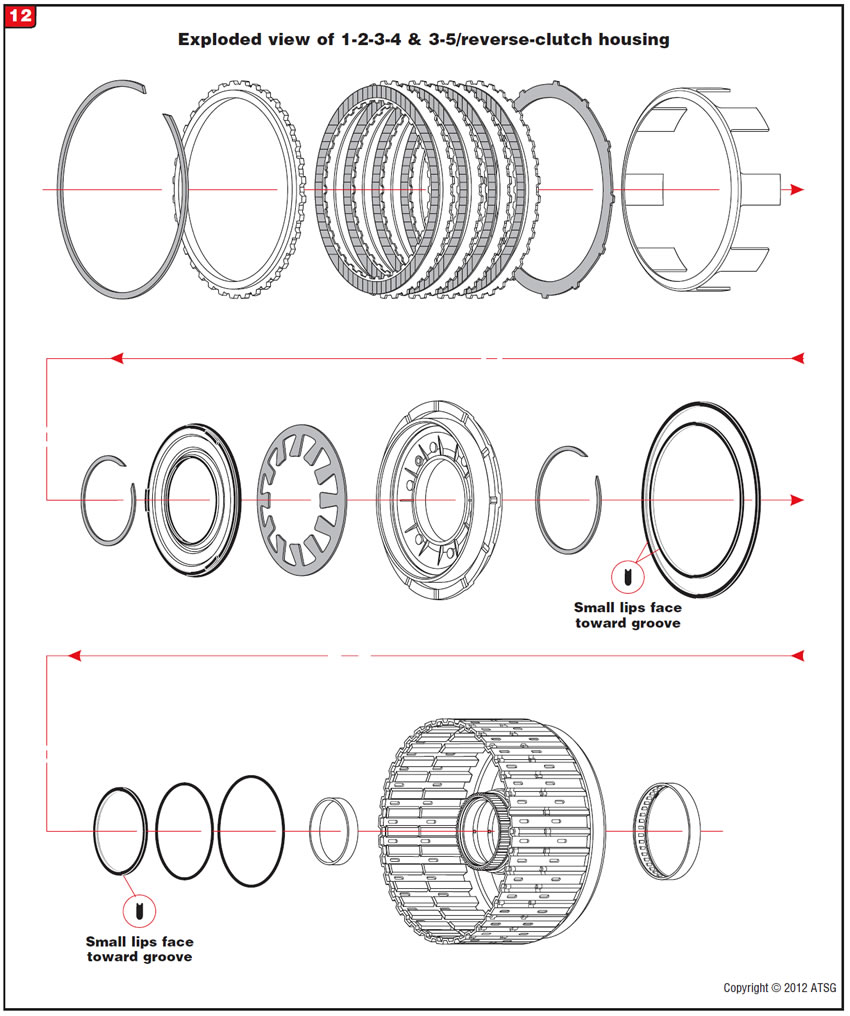

Replace the drum. Refer to Figure 12 for a complete overview of components of the 1-2-3-4 and 3-5/reverse-drum assembly.

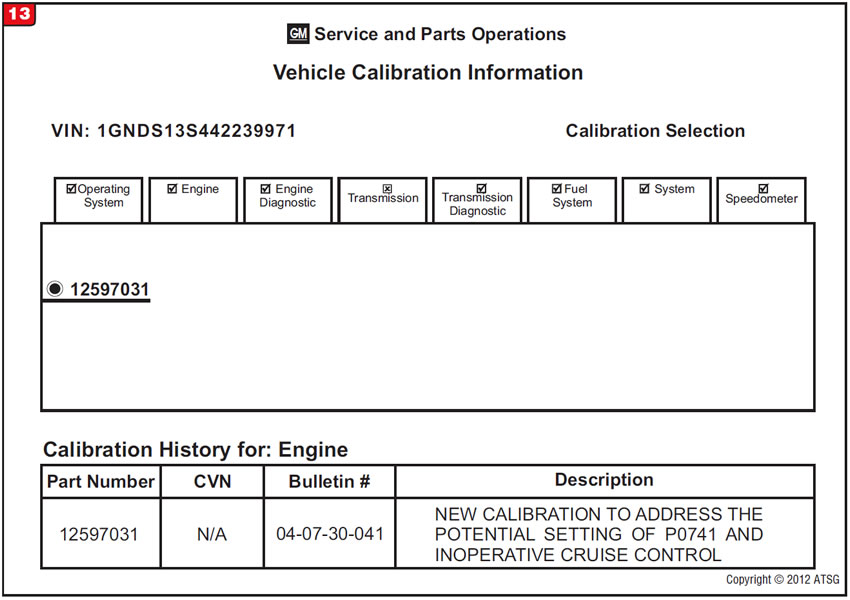

A 4L60-E transmission in a 2004-05 Buick Rainier, Chevy Trailblazer or GMC Envoy or a 2004 Olds Bravada with a 4.2-liter engine has harsh shifts with code P0741 stored, and cruise control is inoperative.

A transmission calibration problem.

Reprogram the PCM with a new software calibration with TIS update version 10.5 or newer (Figure 13).

- Software-calibration part number . . . . . . . .12597031

February 2012 Issue

Volume 29, No. 2

- 4L60/4L60-E/4L65-E/4L70-E: Correcting poor 1-2 and 2-3 shift quality

- 4L60/4L60-E/4L65-E/4L70-E: Third-gear starts

- 5L40-E: Line-pressure instability

- 6L40/50/80, GM6: Delayed, slipping reverse; slide 2-3

- GM 4L60-E: Code P0741 stored, cruise control inoperative