On the maintenance side, a continuously variable transmission (CVT) requires more or the same frequency of fluid and filter changes as a conventional automatic transmission, and many of the basic procedures are the same. On the diagnostic side, a CVT transmission is less complicated internally than a six- or nine-speed transmission.

Like any automatic transmission, the condition and level of fluid in a CVT unit will determine the performance. The color of the fluid for some CVTs is green or yellow. The fluid can darken over time as it is oxidized, just like the red stuff.

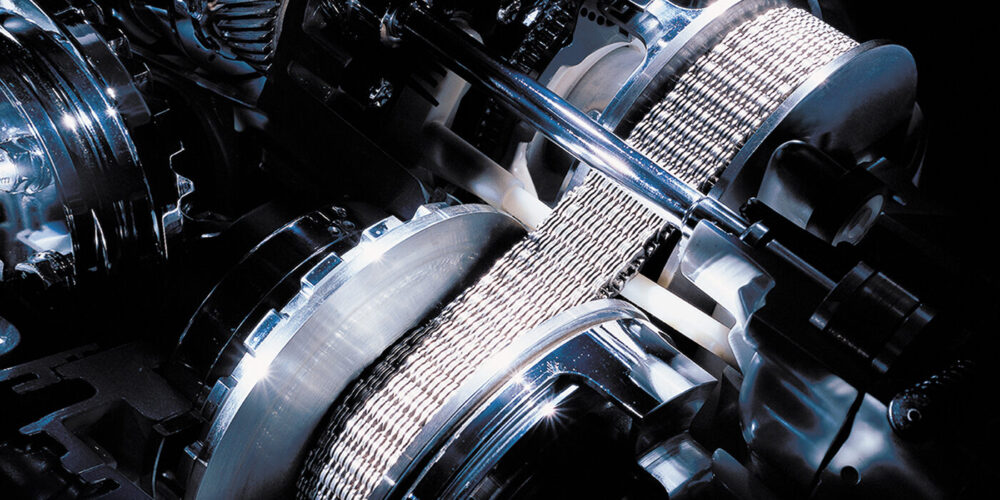

CVT fluids are different than automatic transmission fluids for three reasons. First, a CVT fluid must protect against wear to the belt or chain. Second, the fluid has high shear stability due to the high-pressure requirements to operate the variators and pump. Third, the fluid must work with and protect the friction materials of the forward and reverse clutches along with the start clutch, if so equipped.

Temperature is another unique requirement of constant velocity transmission fluid. The fluid should be up to temperature for the variators and clutches to work as intended. Many of these transmissions use a warmer that uses engine coolant to get the transmission fluid up to temperature faster.

The warmer can also be a cooler when the fluid is lubricating and cooling the internal components. Some CVT systems can have a complex system with thermostats to keep the fluid at the correct temperature. For example, there could be a combination of oil/coolant and oil/air coolers.

As for the condition of the fluid, you might be alarmed when you pull the pan on some CVT units. On the magnet and pick-up screen, you might see a lot of metal debris during the first fluid change. This is normal for a CVT. The metal is from the chain or belt. The path of the fluid is designed so this debris is captured by the magnets, pick up and probably an inline filter.

The fluid level is critical for a vehicle with a CVT. If there is too little fluid, the transmission will not shift properly, and air can enter the valve body of the variators. An overfilled CVT can cause the fluid to be aerated by coming into contact with moving parts. The air can change how the pulley and solenoids control the position of plates. This can cause slipping and incorrect ratios codes. Also, the lack of lubrication can damage the belt or chain.

Setting the fluid level is critical after a fluid or filter service or any repair where fluid was lost. To check and set the fluid level, you will definitely need a scan tool and maybe a dipstick.

Any transmission fluid will increase in volume as it is heated. Many CVT fluid manufacturers have a recommended temperature range to check and set the level. This temperature needs to be checked using the sensor mounted to the valve body. Guessing the temperature or using an infrared thermometer is not an option.

The other reason for a specific temperature is regarding the cooler for the transmission. Most coolers are controlled by a thermostat and will not circulate fluid until a specific temperature is reached.

Some CVT systems will have a dipstick, while others will require a special dipstick tool that can be inserted into a port. But, some transmissions will use an overflow tube in the pan to set the final level.

Not following the recommended procedures can lead to an under- or over-filled transmission. Often, this mistake is realized when the driver leaves the shop. The symptoms could be poor shift quality and noise.

Due to the higher pressures inside a CVT, you are going to need a new pressure gauge that is rated for 1,000 PSI or higher. What can pressure readings tell you? A lot. The typical CVT will have pressure ports after the pump, variators and forward and reverse clutches. In addition, some CVTs will have ports for the torque converter lock-up and start clutch.

What can you test with pressure readings? Just like an automatic transmission, pressure readings can confirm the mechanical operation of the actuators, the accuracy of the pressure sensors and if there are any internal leaks.

In the service information, you can find the specifications for the pressure readings for the different hydraulic circuits; the hold and release pressures for a given circuit. In the case of the variators, the pressures can vary with the commanded ratio by the TCM. Even if you have a reading of the line pressure, you still need to verify the electrical operation of the solenoids.

This article was originally written for our sister site, Import Car.