Up To Standards

- Author: Michael Weinberg

- Subject: Learn how the synchro works

- Issue: Computer-aided shifts

Since the invention of the motorcar, designers and engineers realized that they needed to make the torque generated by the motor usable and efficient. This led to the creation of the transmission, which made the transfer of torque from the engine usable and smooth.

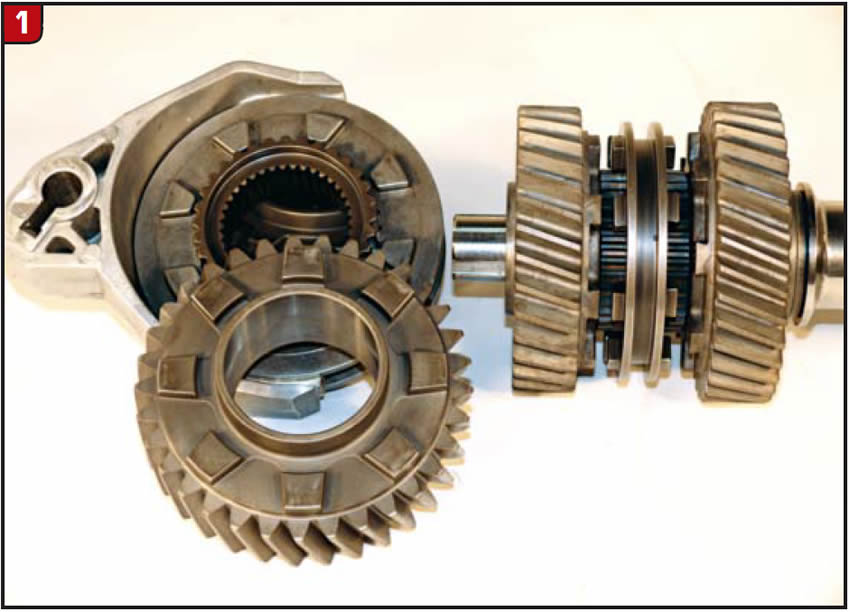

The early manual transmissions were not synchronized and required a high level of driver skill to operate. Then the development of the synchronizer occurred and the ability to change gears became a much simpler job. Smooth, clash-free shifts were simple to obtain. The driver stepped on the clutch, causing a disconnect between the engine torque and the gear box. The synchronizer consisted of:

- a hub splined to the main shaft,

- a sliding sleeve splined to the hub that was moved by a shift fork connected to the shifter linkage, and

- a synchronizer ring that moved with the sliding sleeve to block the engagement of the sliding sleeve, with the speed gear being selected until the shafts speeds inside the transmission were equalized.

Early manual transmissions had an unsynchronized low gear and reverse gears. This meant that the driver could not engage 1st gear while moving without a clash and the resulting noise and damage to the gear. Talented drivers soon learned to “double clutch” and make an unsynchronized shift.

Double clutch is also known as “heel and toe” shifting because the driver would use the ball of the right foot on the brake and rollover the heel of the foot to “blip” the throttle to raise engine rpms. The process goes as follows:

- The clutch is depressed, and the shift lever is moved to the neutral position.

- The clutch is then engaged and the throttle is used to rev the engine to higher rpm.

- The clutch is then depressed and the shift lever moved to the gear to be selected.

If the throttle blip was to a high enough rpm level, a clash-free shift occurred, which required some skill and talent. Double-clutch gear changes are still used today by race drivers and in heavy duty trucks that are not equipped with synchronized transmissions.

The synchronizer ring or blocking ring is a wet clutch that is moved onto the cone of the speed gear to increase or decrease its rotational speed. It has some side-to-side movement and will not line up with the engagement teeth on the speed gear until the main shaft speed has equalized with the input shaft speed. To make this clearer, when the clutch is depressed, engine torque is disconnected from the input shaft.

As the input slows down to below engine idle speed, the main shaft and speed gears are rotating at road speed as the drive shaft and rear wheels are driving the transmission main shaft.

Having the transmission in neutral with the clutch engaged, you can now match input to main shaft speed by blipping the throttle to the required rpm. The synchro ring replaced the double clutch by grabbing the gear to be selected and matching its speed to that of the main shaft.

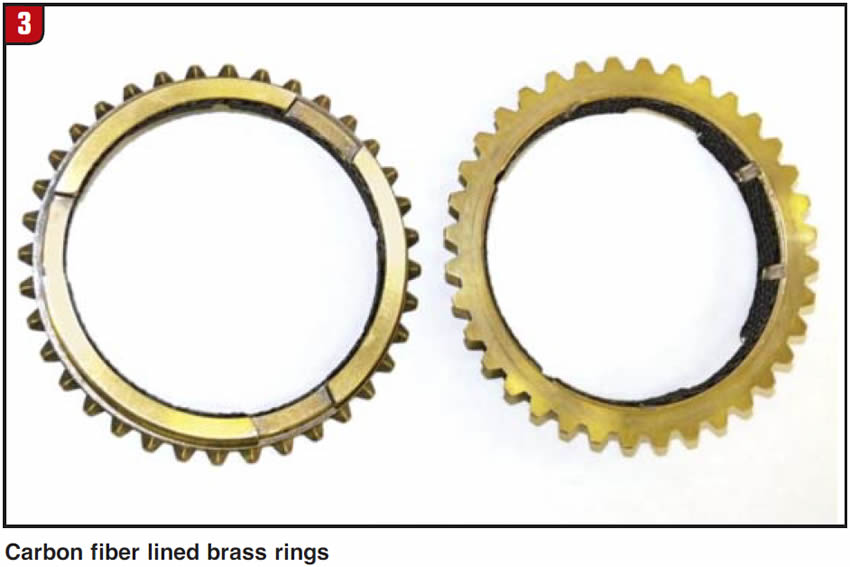

Everyone can use a zipper, few know how it works, which is much the same with synchronization. Easy to use, hard to understand and diagnose. There is always ongoing development and refining of any design, and synchronizers are constantly being made better. For instance, to get more friction from the ring to the cone of the speed gear, one would need to increase the friction surface area. It is possible to do this with a better friction material, which is today carbon fiber or other synthetic materials that have a better coefficient of friction than the old-design brass or bronze synchro rings.

One could increase the size of the ring’s diameter to create a larger friction service. This is impractical as it would increase the overall size of the gear box, increasing weight and making the design a nightmare to package into the current smaller and lighter automobile. The current answer is double and triple cone synchro rings, where you have doubled or tripled the friction area without increasing the diameter of the synchro ring. This produces an excellent shift feel and smoothness and the ability to make shifts at much higher engine rpm without gear clash.

As the current vehicles are equipped with huge computer capability, some of that computer power is now being used to improve shifting and reduce the pressure on the synchro rings.

This computer assisted shift is called rev matching. The first car to use the technology I believe was the Nissan 370Z. As the driver went into a gear change, the computer would read road speed and engine rpm, and automatically blip the throttle during the shift to make the synchronizer ring have less effort to match the gear speed to shaft speed. Rev matching is now part of the new C7 Corvette design, which uses a dual mass flywheel, a dual disc clutch, and the computer to match the revs in an already smooth shifting Tremec 7-speed manual transmission. The driver now has a lower skill requirement due to computer aided shifts. A lot of innovation comes into the designs in passenger cars from racing.

We now have dual-clutch transmissions that are paddle shifted with the computer blipping the throttle making very quick shifts possible without using a clutch pedal. The clutch is there but the shifts are being controlled electronically without driver intervention. Back in the good old days many race transmissions did not have synchro rings, but they used gears and sliding sleeves known as “dog rings.” This meant that all one had to do was to lift off the throttle and pull the shifter into the gear desired without using the clutch on upshifts. It was still necessary to double clutch the downshifts – although many drivers were skilled enough to lift off the throttle, push the shift lever into neutral and blip the throttle while engaging the desired downshift gear without using the clutch. All of this showed up on elapsed shift times which could lower lap times, but dog-ring transmissions are not suitable for everyday street driving.

Another development is the sequentially shifted transmission in which the traditional H pattern shifter is now replaced by a gear selector that works in a straight line. The driver starts out in 1st gear and then moves the shifter in a straight line through the rest of the gears and then back in the direction of the next lower gear for down shifts, with computer-assisted clutching and rev matching. The drawback of sequential transmissions is that if you lose a gear during a race, you may not be able to get past the problem gear to the next gear, where in an H pattern gear box, it is usually easy to drive around the damaged gear. Due to the design and operation of a sequential gear box, the costs are much higher than an H pattern trans. It is possible that further design refinement will drop the costs and sequential shifted gear boxes will appear in passenger vehicles.

The laws of physics remain a constant. Design improvements will continue to make manual gear boxes easier and quicker to shift, increasing shift speed and creating a more efficient use of fuel. Learn how the synchro works and diagnosis and repair will be easier to accomplish.

Mike Weinberg is president of Rockland Standard Gear.