GM’s Steady-State Adapts

With a basic understanding of TAPS, the Transmission Adaptive Pressure System, covered in last month’s article, we will now try to tap into the Steady State Adapt System and what its data can tell us. Not all scan tools provide steady-state data, but I’m convinced that this information is a real help in diagnosing problems in the later GM units. Data for the examples I used in these articles was recorded on either my GM Tech2 or my Mastertech. All the units in the examples shown below are 4T65-Es.

Up to Standards

The cliché “What you don’t know can’t hurt you” is way out of date. The single most-important commodity in the world we operate in is knowledge. Information – and that means good, factual information – is the only thing that stands between us and expensive failures. Our quest for information will include a good working knowledge of the operation of the complex systems that comprise the modern motor vehicle and their relation to one another, feedback from the customer to fully understand their problem and the results they want you to achieve, and a thorough and complete observation of the vehicle you are working on.

Another Cross-Connect Scenario

1998 to 2000 Kia Sportage and Sephia have the idle-air-control valve and the throttle-position sensor relatively close to each other. Figures 1 and 2 show the setup in the Sephia, which is similar to that in the Sportage.

June 2005 Issue

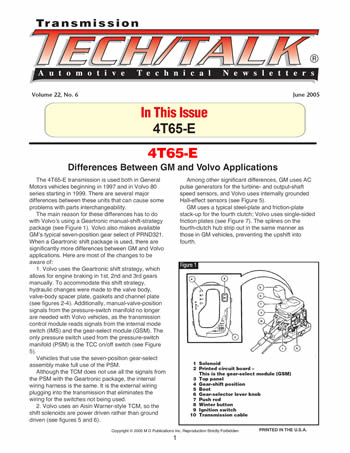

4T65-E

Differences Between GM and Volvo Applications

The 4T65-E transmission is used both in General Motors vehicles beginning in 1997 and in Volvo 80 series starting in 1999. There are several major differences between these units that can cause some problems with parts interchangeability.

May 2005 Issue

Issue Summary:

After overhaul the unit exhibits long, drawn-out shifts when performing under high load or at wide-open throttle.

Before or after overhaul, the transaxle exhibits second-gear starts or shifts out of sequence, even though a scan tool indicates that the computer commands are correct and electrical signals at the transaxle harness connector have been monitored and verified.

A vehicle equipped with the 4T65-E comes in with a complaint of no 3-4 shift at any time.

Some 2003-model 4T65-E transaxles have a newly designed input and third pawl-clutch assembly instead of the previous-design input and third sprag clutch.

Tag, You’re It! A Case of Injustice?

“The Hazardous Waste Manifest System is a set of forms, reports, and procedures designed to seamlessly track hazardous waste from the time it leaves the generator facility where it was produced, until it reaches the off-site waste management facility that will store, treat, or dispose of the hazardous waste. The system allows the waste generator to verify that its waste has been properly delivered, and that no waste has been lost or unaccounted for in the process.”

On-the-Road Diagnosis

The car in Figure 1 is a 2000 BMW 528i that had been to a couple of transmission shops before I got to it. The complaint was that the transmission was in failsafe mode. The car started and moved but would not upshift. The other shops also said they could not communicate with the transmission EGS module.

Advancing Clutch Technology

Last month we discussed pioneering new technology for differentials. Here we look at the cutting edge of manual-transmission clutch technology.

Playing TAPS on Pressure Systems

TAPS is one of the latest acronyms to join the list. It stands for transmission adaptive pressure systems, and it is used both for shift adapts, which establish pressure control during the shift, and for steady-state pressure control, the adapting-pressure requirements for a given gear after the shift is completed.

April 2005 Issue

In This Issue

The ZF-5HP-24: Preliminary Information

Identification Guide to BorgWarner Transfer Cases

One of the most time-consuming and annoying problems associated with manual-transmission and transfer-case repair is unit identification. It is difficult to diagnose, buy parts or remanufactured units, and create a correct estimate for the customer when you cannot identify which unit you are working on. All units leave the factory well marked with decals, metal ID tags or both, but through use, weather and previous repairs, many of these ID devices become illegible or non-existent.

A Case of Mistaken Identity, Part 2: Impossible?

It is important that you identify the problem immediately. Do not road-test the vehicle to check out the forward speeds if you are having a problem with reverse. The reduction band must be anchored to the case by the anchor stud to prevent rotation. If you try to drive the vehicle without the stud in place, the band will rotate, wedging itself between the drum and case. This will prevent the drum from rotating and will burn the clutches that try to apply for a given gear. If the clutches lose their service ability, then the transmission must be removed.