Up to Standards

- Author: Mike Weinberg, Contributing Editor

Last month we discussed pioneering new technology for differentials. Here we look at the cutting edge of manual-transmission clutch technology.

Over the years manual-transmission clutch sets have undergone a steady gradual improvement. The development of the Belleville diaphragm spring, which replaced the three- and four-lever designs that were common, increased torque capacity while reducing pedal effort considerably.

Clutch friction material underwent a dramatic change with the outlawing of asbestos products. However, the present market has put strong demands on the clutch manufacturers to develop new product. This product has to be able to fit in the smaller packaging requirements of the new vehicles, be of lighter weight, and handle high horsepower and torque loads relative to its size. In other words, we need to develop an 8-inch-diameter clutch set that will have the torque rating of a 12-inch clutch.

The reason for this demand is the huge rebirth of vehicle performance. The advertising adage “sex sells” has been fully absorbed by the automakers. Now the sexy image of the car translates into higher horsepower, better handling and better brakes. Couple this with the phenomenal increase in tire technology and the late-model cars are perhaps the best-performing vehicles ever. For under $30,000 you can buy a new car off the showroom floor that will be quicker, stop better and out-handle purpose-built race cars I drove 20 years ago.

Every manufacturer seems to be in a position to offer high-performance vehicles to take advantage of the huge growth in racing spectatorship and the ever-increasing popularity of the import drag racing, and the hugely popular “drift” scene that is sweeping the country. This is by no means a passing fad. The Subaru WRX STI, Mitsubishi Lancer EVO series, Saturn Ion Redline, Chevy Cobalt SS, Ford Focus, BMW Mini Cooper (supercharged) and Nissan 350ZX are examples of reasonably priced vehicles with loads of performance.

Every major automaker now has a performance-development group that is putting real sizzle into cars that were not considered “hotrods” before. Chrysler has brought back the “Hemi,” and Cadillac has introduced a CTS-V model equipped with a Corvette Z06 powertrain complete with a six-speed Tremec T56 transmission. Ford has brought back the Mustang Cobra with a vengeance (about 500 hp), and the Pontiac GTO has returned. There are more supercharged models from the factory than ever before, and even conservative manufacturers like Volvo are building hot-performing vehicles.

This performance movement doesn’t stop at the factory. Because of the competitive nature of human beings – many people want something above and beyond what their neighbor has – there is a multibillion-dollar market for so called “tuner cars.” A tuner car is best described as a factory-produced vehicle that has been massaged by a specialty shop to improve performance even further. This is done by a careful matching of engine, drivetrain, brakes, suspension pieces and exhaust to add even greater grunt than supplied by the factory. Usually these packages come in stages or levels that fit the customer’s pocketbook and need for speed. As a result, the automakers have placed a huge demand on their suppliers for parts capable of handling the increased performance capability.

On the manual-clutch side, full racing clutches have always been available. These clutches however, are useful only for racing and are basically on/off switches. They engage so quickly that they cannot be driven on the street, which is why you see the race drivers lighting up the tires when they leave the pits, and the crews pushing the race cars from the paddock to the track. For the purpose of this discussion we look only at new technology that makes performance clutches suitable for street-driven vehicles.

The leader in clutch technology today is clearly Exedy Corp., the parent company of Daikin Clutch Corp. Most of you are familiar with Daikin Clutch as being the OE clutch supplier for most Japanese vehicles and having an ever-increasing presence in the American and European markets. Daikin markets its performance and racing clutches under the Exedy name and is the world leader in advanced clutch material and design.

Its main areas of research and development have created new types of clutch-facing material, special damping designs, lighter weight and stronger pressure plates, and lightweight chrome-moly flywheel assemblies. Reduction in the weight of the clutch assembly and flywheel improves acceleration, reduces rotating mass on the crankshaft and lowers shift inertia. Shift inertia is the tendency for the clutch components to keep spinning during the shift sequence, which slows clutch-release times and increases shift effort and wear and tear on the synchronizer components.

A tremendous amount of research and testing goes into the development of friction material and components that permit the lighter-weight clutch set to offer comfortable pedal effort, increased torque capacity from smaller-diameter clutches and the ability to dissipate heat more effectively, and still perform comfortably for street-driven vehicles.

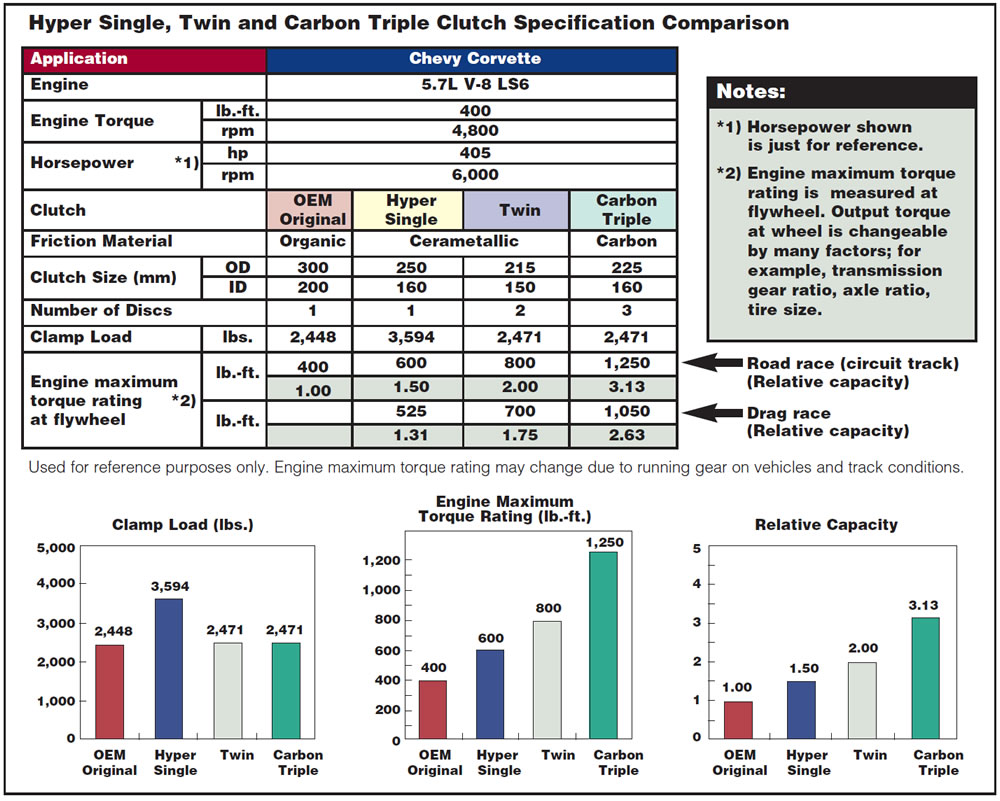

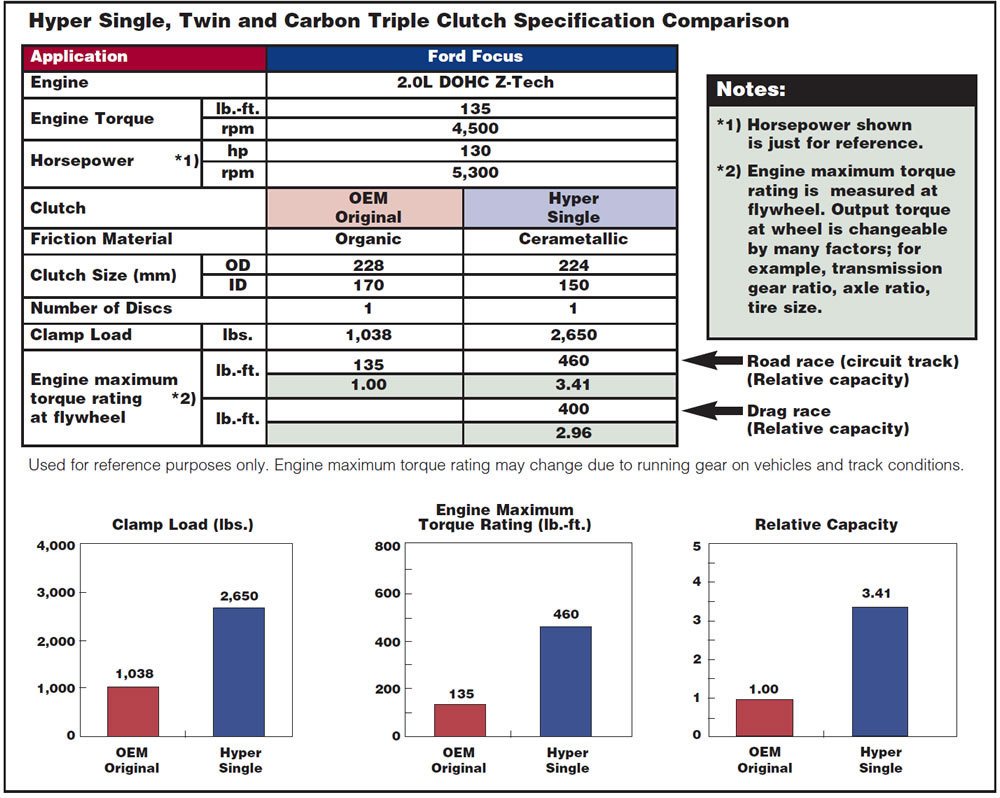

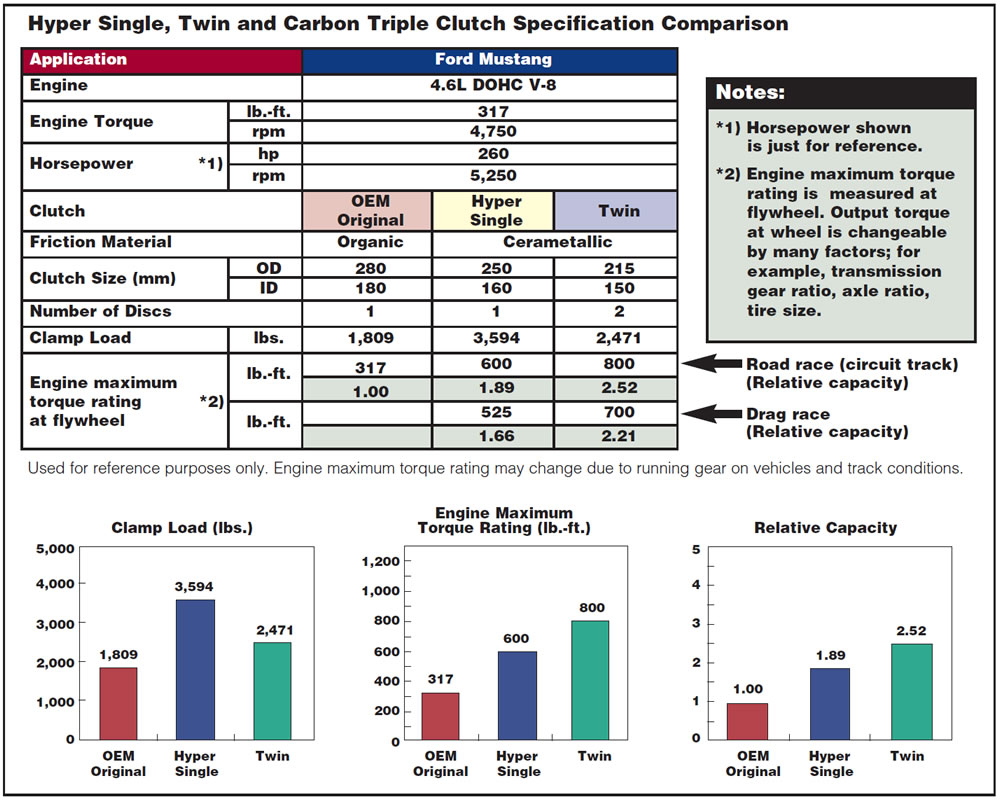

Clutches for higher-performance vehicles and modified engines need to be matched for the correct torque output. Horsepower is not as relevant as the torque curve and capacity of the engine and the use to which the vehicle will be put. Cars that are modified for higher performance will be used and tried out by the owner. A street car that occasionally is drag-raced will require a higher-capacity clutch than a street-driven car that is sometimes used for road race or auto cross. These clutch-replacement sets come with improved friction material and pressure plates while being direct replacements for the stock clutch. Improved organic disc facings and pressure-plate design will improve the torque capacity over stock units by 32% to 70%.

The next step up in torque capacity is the cerametallic friction material. This material is known as T5001 and is a ceramic and metal alloy. It is lighter, with greater heat absorption, much lower shift inertia and a much higher coefficient of friction. This means that the disc requires less surface area than an organic facing. This clutch will typically increase torque capacity by 62% to 133%.

For greater performance gains Exedy has developed a Hyper Clutch Set that is available with single, twin and triple discs. These clutch sets are equipped with a forged-aluminum pressure plate, cerametallic six-puck clutch disc or discs, and a lightweight chrome-moly flywheel.

One of the problems with a stock pressure plate is that the cover is stamped steel. A press-formed cover will deflect with high heat and lose clamp load. The forged-aluminum pressure-plate assembly is much stiffer than stamped steel and will not deflect. The added cover stiffness allows the use of a higher diaphragm lever ratio, which increases clamp load while decreasing pedal effort. These clutches are available in both push and pull styles to replace the stock unit as a direct bolt-in. Exedy also has developed a patented quick-release throw-out bearing for the pull-type clutch that can be removed from the pressure plate with a flat-blade screw driver and a twist of the wrist, greatly simplifying R&R work. The entire clutch assembly and lightweight flywheel are burst tested to 15,000 rpm.

The top of clutch friction technology is the carbon clutch. Using the same forged-aluminum pressure plate and the chrome-moly lightweight flywheel, these clutches also are available with single, twin and triple discs. The disc material is cross-lamination bonded carbon for maximum rotational strength. The carbon clutch material is one-third the weight of cerametallic discs and has 22 times less thermal expansion. The carbon discs can handle almost 2,000° F without premature wear. These units can handle up to 1,250 horsepower in road-race applications and 1,000 hp in drag-race use.

All these advanced clutch systems are designed as direct bolt-ins, with no need for any engineering by the installer. They use the OE hydraulic release systems as originally installed on the car. Note: Many of the late-model hydraulic release systems have been designed with restrictive orifices in the pressure line to help stage and time the clutch release. It is frequently necessary to enlarge the orifice in the hydraulic line to obtain a better clutch release even when you’re replacing stock components.

Every shop can use more high-profit work. You can offer added value to your customer with a performance vehicle by informing them of the upgrades in clutch technology that are available. Many times, vehicle owners have had the torque and horsepower of their vehicle upgraded without considering the effect of this increase on the powertrain and other components.

Usually the first victim of the added power is the clutch. You need to make sure of your customer’s intentions as to how they will use the vehicle and if they have made or plan to make performance changes. You will find it really enjoyable to have a customer who wishes to spend money rather than the usual unhappy camper who has to replace a transmission. Take advantage of the highest technology available and you will find that it is harder to go broke making a good profit.