Up To Standards

- Subject: Strategies for remaining competitive

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

He who makes the fewest mistakes wins

We work in one of the most-technically advanced industries on the planet. The modern motor vehicle is a complex system of mechanical, electronic, hydraulic and computer control. Part numbers have expanded beyond any imagination, prices are sky high and will continue to rise as inflation expands, and comebacks are extremely expensive.

The car dealers and the insurance companies have become major competitors, taking away an increasing part of our customer base. This means that to survive and prosper we have to be right every time in our business model. As in any competitive area such as pro sports, the winner is usually the team or individual who makes the fewest mistakes. A mistake by definition is an error in judgment, performance and execution, planning, strategy or all of the above. We are all familiar with the mistakes made that result in comebacks, which cost you dearly in labor, parts, lost opportunity costs (working on something for free when you could be making money on another repair) and loss of customer confidence. What often goes unnoticed is the strategic decisions made by the business that can result in greater losses of money and opportunity.

Pricing your work incorrectly is one of the most-common strategic errors. Does your labor rate reflect your cost of doing business with a percentage of profit for the amount of billable hours, or is it a number that is comparable to or cheaper than your local competition? Do you know what the fiscal burden is for each employee? Do you know what it costs to turn the key in the door every day, so that your pricing reflects the absorption of those costs plus a correct profit percentage? These are all vital data without which you have no way to price your work correctly.

Most shops are very price conscious in their purchasing, but a low price on parts is not necessarily a built-in profit. If the quality of the parts does not match up to OEM equipment or improved product engineered to overcome design defects, this is actually a losing proposition.

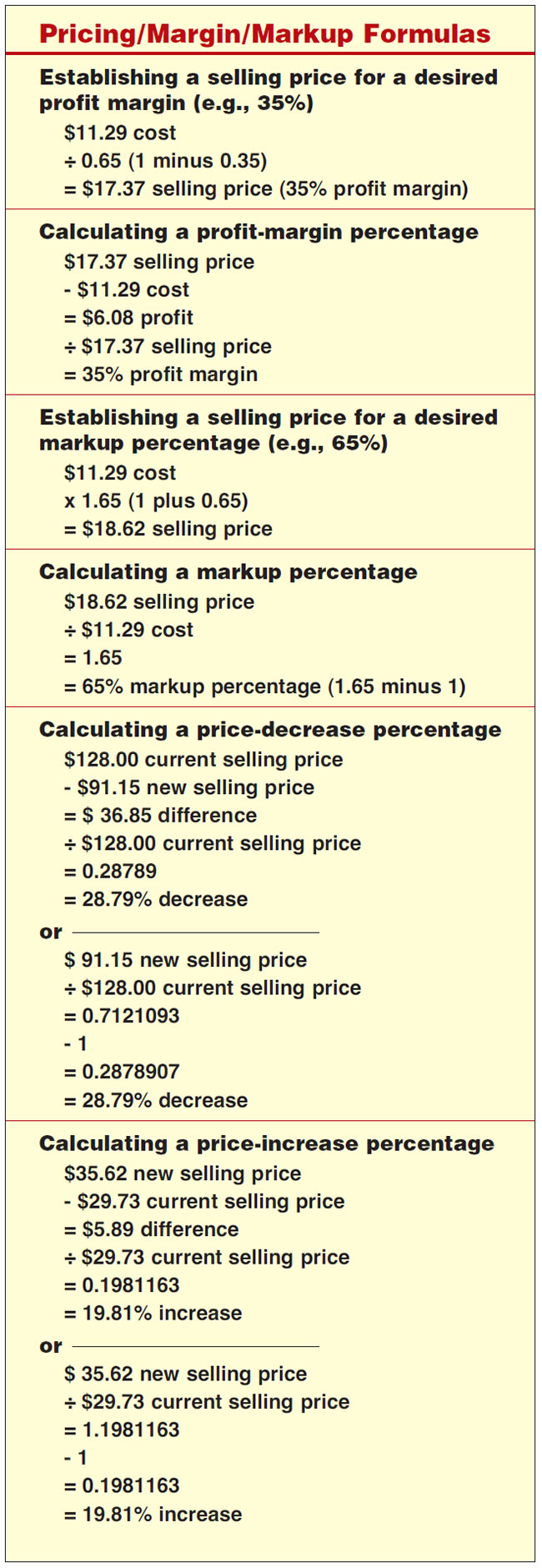

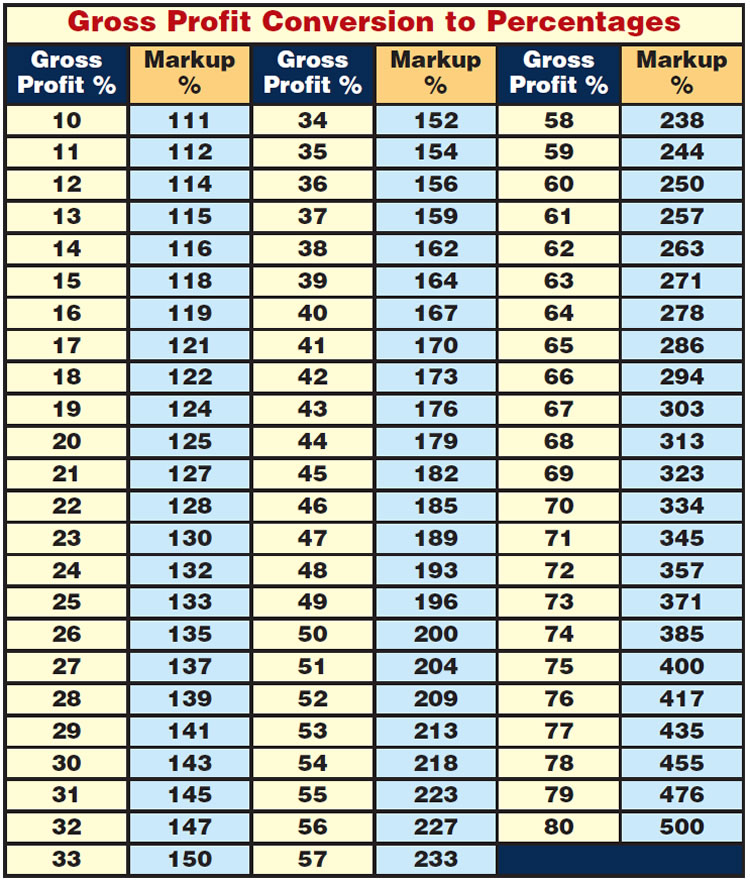

Are you marking up the parts sold to give a net profit of at least 40%? Do you understand the difference between markup and margin? Margin is the actual profit you make on a part, and the desired margin decides the markup you put on the part. For example, if you wish to make a 50% profit margin on a part, your markup would have to be 100%.

Is your supplier giving you added value for the parts you buy? It is extremely important to compare apples with apples when making a buying decision. If you are buying on price alone, are you buying exactly the same product or a cheaper offshore version that will create a warranty problem? Is your supplier providing you with technical help after the purchase? That is a value-added service that makes a low price meaningless if you cannot get help in using the product.

We provide a technical hotline that is free to our customers. You would not believe how many times a shop will call asking for technical help on parts they bought somewhere else. When we ask why they didn’t buy from us, they might answer, “We got it cheaper from XYZ company.”

Our reply is, “Why don’t you call them for help?”

They answer, “We did, but they just sell parts and can’t help us technically.”

Our reply is: “This obviously did not amount to any savings, did it, because you can’t fix your problem without technical expertise. We have no idea whose parts you bought, so we don’t know if the parts are good or correct. On the other hand, would you bring your own steak to a restaurant and ask them to cook it for you?”

Align yourself with suppliers of parts that are OEM or better quality and have the added value of technical advice when problems arise. The few dollars saved on the purchase are lost in the labor wasted trying to get the unit to function properly. Remember that you are not buying these parts for your own use; you are buying them to sell to the customer. If your margins are correct a few dollars saved on the parts means nothing.

I am always asked how you can mark parts up over the car dealer’s suggested list price. The dealer price is by law a “suggestion” and has nothing to do with reality. How about the dealer marking up the latest hot model way over list when demand is heavy and supply is short? That suggested list price will give you a margin of 10%-25% on average. You cannot stay in business on anything less than 40%. You are giving your customer value added in the sale by laying out the money for the purchase and getting the parts, which means he does not have to take time off from work to do so, and you are making sure he gets the correct parts the first time, as he has no expertise in this area.

Another strategic flaw involves poor diagnosis and less-than-thorough inspection of the unit when providing your customer with an estimate. On the factory-reman level, about 52% of the cores returned were not faulty to the point of needing a unit. Be careful and thorough in your diagnosis and inspection of the vehicle.

If the car is not drivable when you get it, make sure to note this on the work order and make it clear to the customer in writing that there could be other damaged or worn parts that will show up only after the vehicle is made drivable. Every day a shop will replace or repair a transmission and then find out that the transfer case or a differential is also bad. Make sure you take the extra time to really inspect the vehicle bumper to bumper so you don’t fall into that trap.

When you have determined that a component such as a transmission, transfer case or differential is bad, do not write that price quote before you completely disassemble the unit, clean it and make sure you list all the parts needed for a complete repair. Every part you miss will come out of your pocket, not the customer’s. I would like to meet the man who can up-sell a quoted price after the customer has agreed. If you want to quote looking through oil and dirt or just a partial teardown, you will get bit more times than not. The extra time involved will make you money and end a lot of hassles.

One of the greatest causes of lost time and money is noise complaints. Shops replace many a unit, particularly on transfer cases, only to find the noise is coming from one or both of the differentials. A thorough evaluation is not a waste of time but an investment in being right the first time and protecting yourself and the customer.

Everyone gets spoiled by “just-in-time” delivery. This leads shops to keep parts inventory as low as possible, which with the huge variety of units and parts is a good idea. However, part of your strategy should be to keep a correct inventory level of the parts you use all the time. The only thing that makes all men equal is time. Every human has the same amount of time available every day, and when that time has passed it can never be regained.

If you get your delivery every day by UPS or FedEx, remember that it is usual but not guaranteed. Weather and other factors can create problems in the delivery unless you paid for next-day delivery. There is no need to go to that expense daily, but if you have a rush job for one of your better accounts buy the guaranteed service. Conditions may conspire so that you don’t get a shipment at the guaranteed time, but at least you have a good shot at getting the job out in time, and if the delivery is not on time the carrier has to pay the freight. What does it cost to have lifts tied up waiting for parts and men ready to work but not being able to do so?

Another critical part of your business model is information and essential tools. Information is the most-important tool of all, and you need to invest in tech services that can provide this anytime you need it. The manufacturers have basically stopped printing repair manuals for us to buy. This means that any fully equipped shop will subscribe to a number of such services to get access to technical-service bulletins, recall info, unit repair manuals, wiring diagrams, and parts illustrations and call-outs. Thankfully, most of the manufacturers have such online subscription services, and the aftermarket companies or associations like ATSG, ATRA and Mitchell OnDemand are well worth the subscription fees.

When a new transmission model or vehicle comes out, some essential tools will always be needed to make the repair simpler and faster. You obviously can’t own or make all of them. If you are giving business to a dealer on a steady basis, build a relationship so that you can borrow the tools until you know that this is something you will need to own because there is enough volume to justify the investment. A number of aftermarket companies provide these tools at reasonable prices, and the time and effort you save in the job will quickly amortize the costs.

We are in a war for market share. Every day you face competition from other local shops, national-franchise chains, the automakers’ dealer networks and insurance companies. One part of your business model should be to defend yourself and this industry from the predatory practices of the insurance companies and the vehicle manufacturers. There is strength in numbers, and you need to join trade associations such as ATRA, ASE and APRA to further your business future.

You can also involve your elected representatives on this level. There is the proposed federal “Right to Repair” law that supposedly would ensure that all the manufacturers make all the repair information available to us. This information is getting increasingly harder to obtain, and I believe that is by design so that the dealer body gets a larger share of the work.

The factories instituted reman programs that removed a lot of dealer work from our shops. They now increasingly contract with their suppliers to make parts “captive,” which means the supplier will not sell them to anyone except the automaker. They do this by buying the tooling needed to make the parts and barring the supplier from selling any parts made with their tooling to anyone else. On high-volume parts the aftermarket will manufacture them because of demand, but no one can make everything.

A second front in the manufacturers’ quest to keep us out of the repair business is to increase their warranty periods to as much as 10 years/100,000 miles, which binds the car owner to the manufacturer until the end of the warranty period. Another step is to make many components available only as replacement units, with no individual components available. This is becoming more and more common both because of a lack of people in the skilled trades to do the work and because when everything becomes a “throwaway item” they are the only game in town and do not have to inventory millions of parts worldwide.

The money and time you invest in industry trade associations will be well spent if we are to continue to have a chance to make a good living.