Shift Pointers

- Subject: Causes of pressure-switch codes

- Unit: AS68RC

- Vehicle Applications: Dodge, Isuzu, Mitsubishi and Nissan medium-duty trucks

- Essential Reading: Rebuilder, Diagnostician

- Author: Pete Luban, ATSG

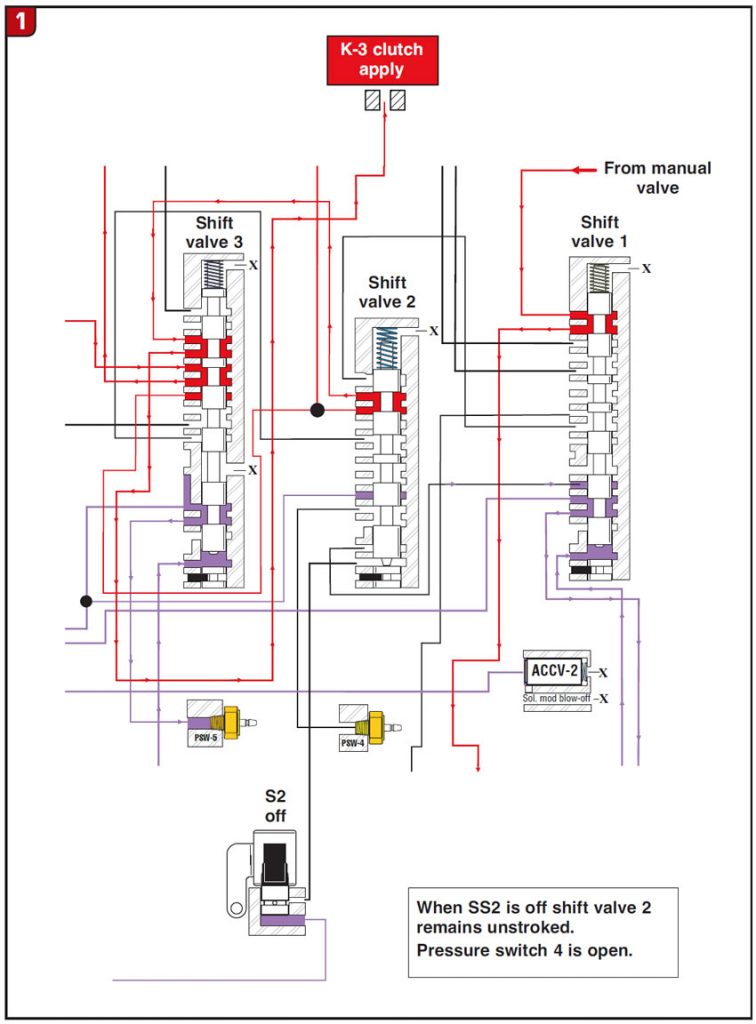

When an Allison 1000/2000 transmission produces a pressure-switch code, it does not necessarily mean the pressure switch is faulty. A solenoid needs to stroke a valve, which then sends oil pressure to the switch to close it. If the solenoid is performing poorly, or the valve is sticking, the pressure switch will not close, causing the associated code to set.

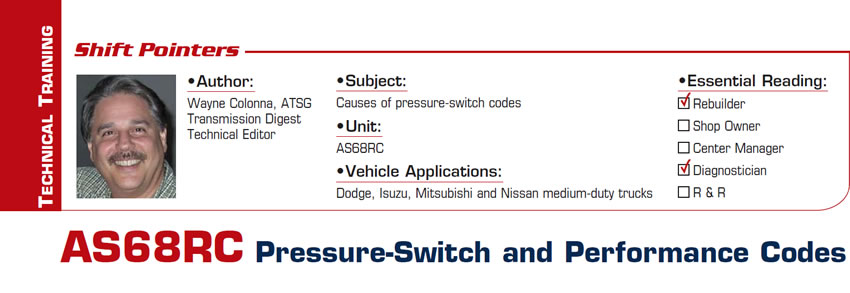

The six-speed AS68RC transmission uses a similar strategy (figures 1 and 2). In addition to Dodge vehicles, this transmission is found in Mitsubishi (AS6), Nissan (M036A6) and Isuzu (A465) medium-duty trucks. With this unit being in Mitsubishi as early as 2005, our tech lines have already received numerous calls concerning this unit, most of which have been in regard to pressure-switch codes.

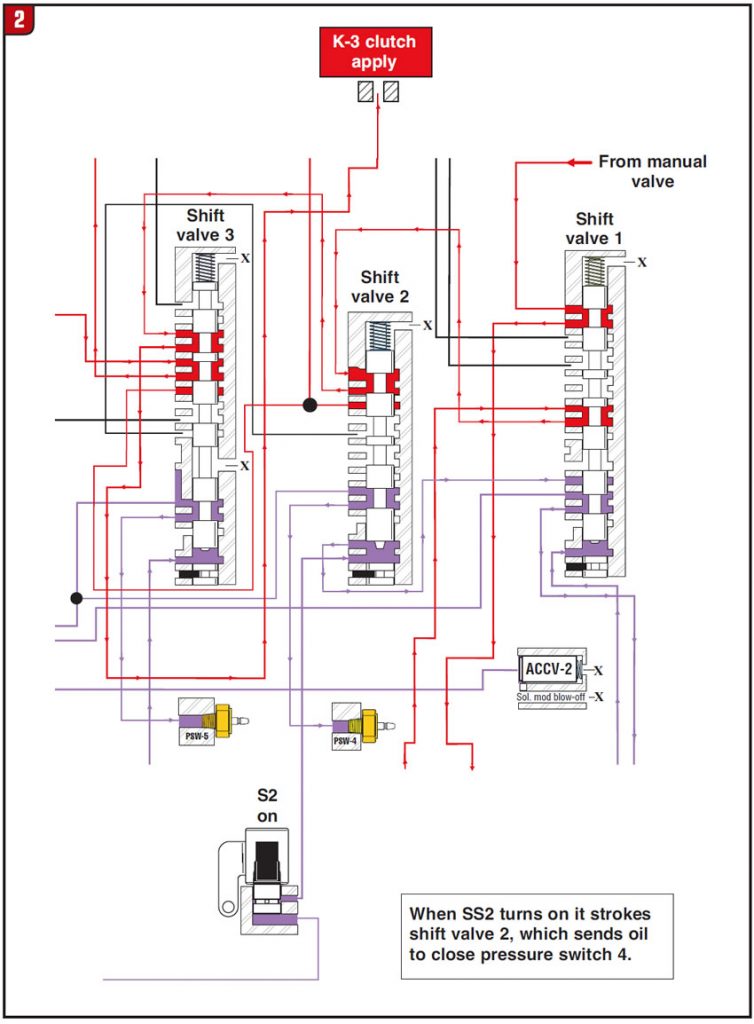

The AS68RC uses a total of eight pressure switches, most of which monitor solenoid activity (Figure 3). When a pressure-switch code sets, the cause can be a mechanically failed solenoid, a stuck shift valve, a mechanically faulty pressure switch or the wire going to the switch being open or shorted to ground.

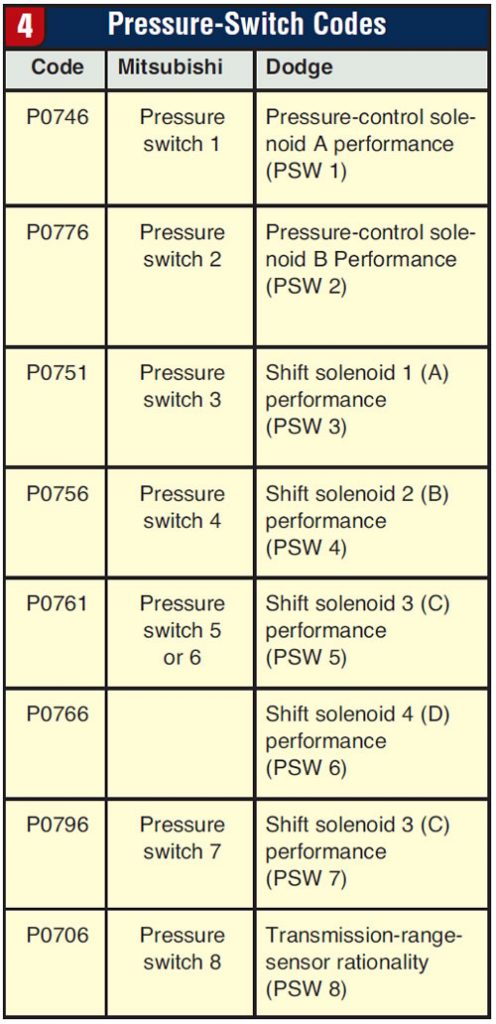

Understanding how a pressure-switch code can set also explains the different ways a manufacturer will present the code. The chart in Figure 4 illustrates this point exactly by comparing Mitsubishi with Dodge.

Mitsubishi chose to assign the code directly to the pressure switch itself; Dodge chose to call it a performance code with the solenoid related to the operation of the pressure switch. The exceptions to this are P0766 and P0706.

Mitsubishi, noticing that the strategy with pressure switches 5 & 6 had related solenoid activity, decided not to split the code and assigned them both to the same code: P0761. Dodge decided to split the code, assigning P0761 to pressure switch 5 through the operation of shift solenoid 3 (C) and P0766 with pressure switch 6 through the operation of shift solenoid 4 (D).

Looking at the hydraulics for this transmission reveals that Mitsubishi had accurately assigned these two pressure switches to one code, whereas the P0766 will be misleading since shift solenoid D does not influence pressure switch 6 to close.

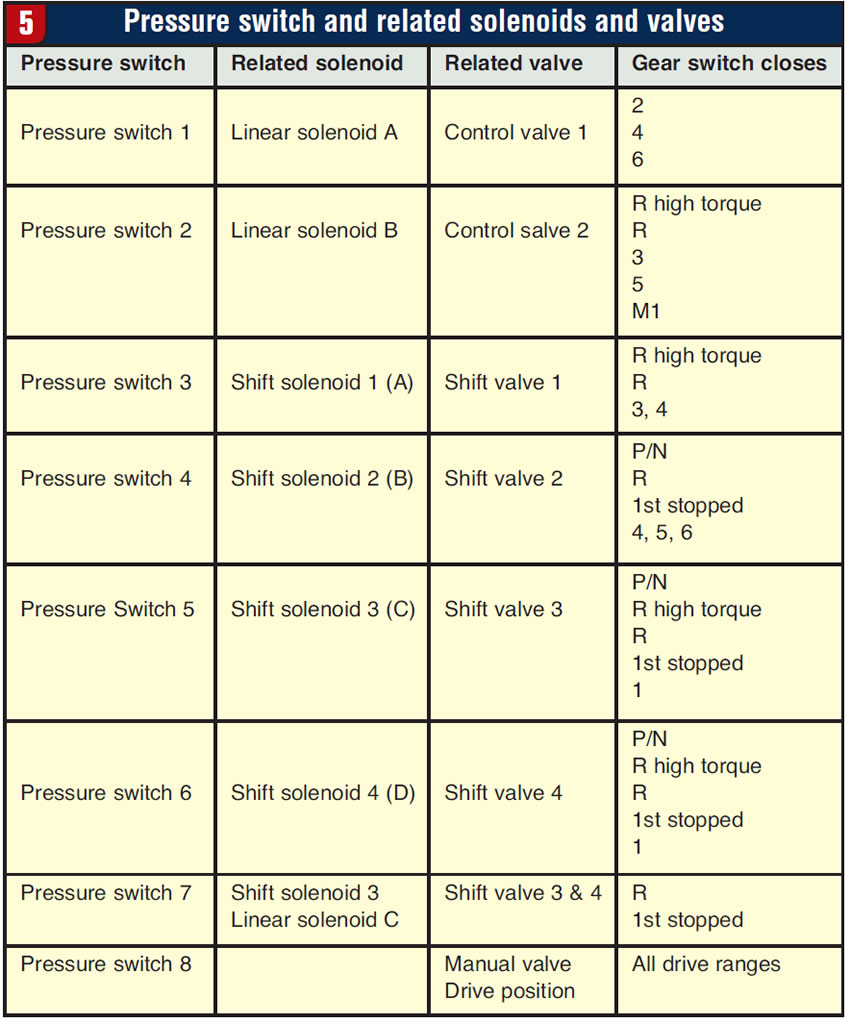

Using the hydraulics to observe which solenoid is used to close a pressure switch also reveals which valves are used, as reflected in the chart in Figure 5. You can see that the difference between pressure switches 5 and 6 is which valve is stroked.

Another interesting piece of information that Dodge provides is the conditions under which these codes set. If there is no detection of an electrical-circuit fault for the solenoid, when the pressure switch is to close it has only 1.4 seconds to do it. Should it take longer than this the code sets. Additionally, the computer looks at the time it takes for the switch to open. For this it has 1.78 seconds; if it takes longer, the code will set. This will explain why these pressure-switch codes come up before ratio codes are ever seen.

Pressure switch 8 differs in strategy from the other seven pressure switches. This pressure switch closes with line pressure supplied by the manual valve in Drive range only. Once this switch closes in drive it stays closed throughout all the shifts. Dodge uses this pressure-switch signal and compares it with the transmission-range-sensor (TRS) signal. Both signals should be in agreement; if they are not code P0706 sets, which is why Dodge defined this code as a TRS rationality fault.

ATSG’s Jim Dial developed complete hydraulics for this transmission, and the information is available in the AS68RC Tech Guide.