Technically Speaking

- Subject: 4R70W

- Issue: Remedy

- Author: Beau Hansen R & D Specialist for ETE Reman

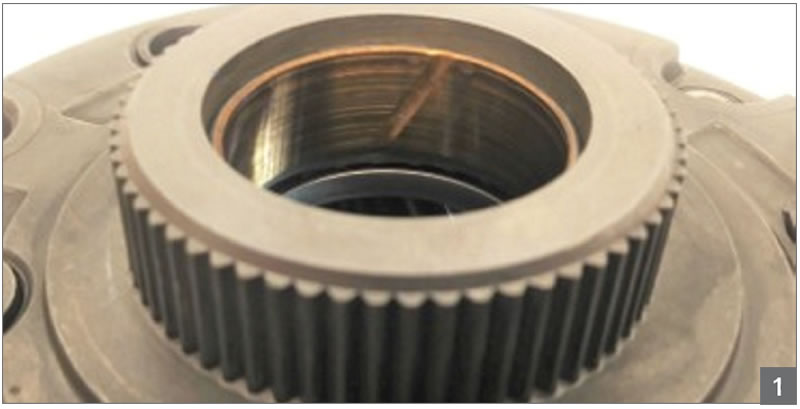

As early as 1993, only one year after the AOD went electronic calling it the AOD-E, did Ford introduce the 4R70-W. Since then, the main ravigneaux pinion carrier has a reputation for failure, particularly with 2004 to 2008 vehicles. This is a weighty carrier which has bushing support at both ends. The mouth side of the gear set where the sun gear and shaft come into as well as the low one-way-clutch device is where the larger of the two bushings is located. The smaller one on the other side is located in the snout that spline into the direct clutch hub. Due to the weight of the gear set, this bushing has a tendency to wear (Figure 1).

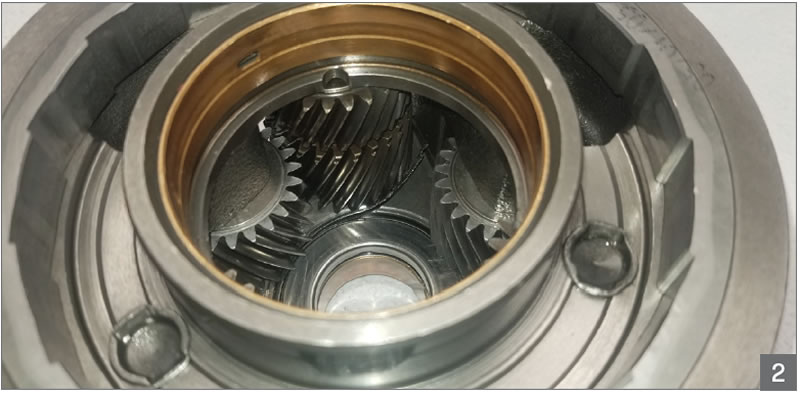

This places additional stress to the carrier’s inside captured needle bearing. In time, the bearings outer diameter collar retainer splits (figures 2 and 3) or the top race cracks (Figure 4).

Once this occurs, pieces get caught up into the pinion gears resulting in catastrophic damage. In 2009, the pocket for this captured needle bearing was made deeper to accommodate a thicker bearing (0.215”). This has lessened the amount of failures, but these bearings do overheat and will need to be replaced (Figure 5).

The bearing that is being used in this updated carrier is exactly like the one Ford uses in their 5R110W transmission for the front planetary. If your shop can lay hands on extra captured needle bearings, the fix is easy. Knock out two small pinion gears and you gain easy access to the bearing for replacement.

If your shop can lay hands on extra captured needle bearings, the fix is easy.

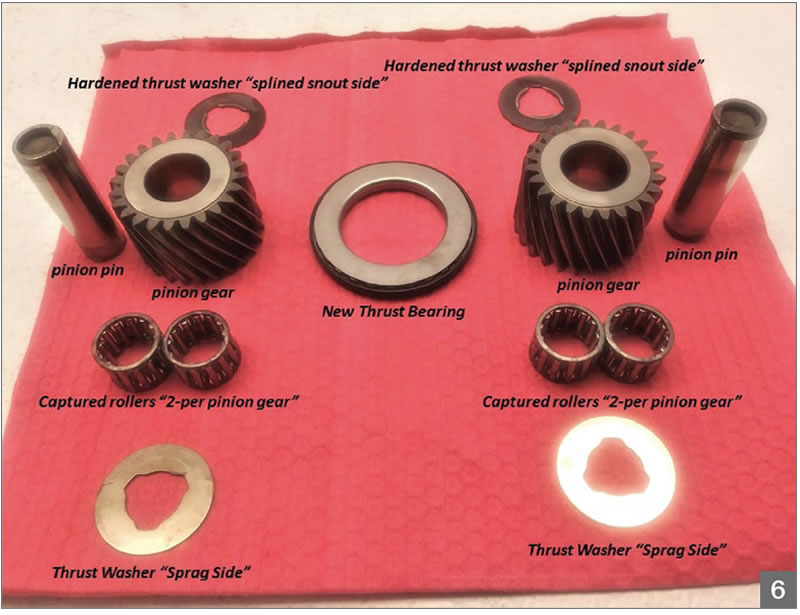

The pinion shaft has captured needle bearings for the pinion gear which makes this an easy job (Figure 6). Do this once or twice and you will find that it’s a 10-minute fix ending with a tac weld on each of the pinion pins.

But what do you do with the early 1993 to 2008 failures? If you spot a failed needle bearing before it destroys the gears, the needle bearing is very close to the one inside the 1999 and later front planetary (.199” thick) of a 4L60-E transmission. Sonnax sells this captured needle bearing separately under part number 77747-01. The same procedure of knocking out the two pinion gears makes this a 10-minute job.

This fix is great when you have a unit in your shop that has yet to experience a catastrophic planetary gear train failure. It becomes a “preventive” part of the rebuild. Inspecting the pinion carrier thoroughly is essential to ensure you are not sending out a ready to blow hand grenade. Here are a few things to pay attention to. Carefully examine the captured needle bearing to see if the collar retainer is split as shown in figures 7 and 8. If it is, you caught a hand grenade before the pin was pulled. This needle bearing will need to be replaced.

Check each of the pinions (both long and short) for drag. The needle bearing cage for these pinions are also known to split as seen in Figure 9. If no other damage has occurred, it can be repaired by harvesting parts and pieces from another carrier. And there can be carriers that you can save for this type of repair as there is yet another area that will need to be examined. And that is the bearing pocket.

Sometimes when the collar retainer splits, before the pieces get caught up into the pinion gears, it can wallow out the side walls which can cause excessive side to side play of the needle bearing (Figure 10). These worn out carriers can then be used for parts and pieces such as the pinion shaft needle bearing cages.