Shift Pointers

- Author: Jesse Zacarias

- Subject Matter: Shift adaptations

- Unit: VW 01M

- Vehicle Application: 1999 New Beetle

- Issue: Slight binding feel on 2-3 shift

In previous articles I have explained the important part that adaptations play in the shift quality and proper operation of a transmission. I have corrected many shift complaints from other shops that just could not get the transmission to shift properly simply by resetting the adaptations.

In this article I’ll use the VW 01M 2-3 shift to explain the hydraulic part of the adaptation. Let’s use the most-recent case I had, a ’99 VW New Beetle with a 01M transmission that had a slight binding feel on the 2-3 shift.

The shift that is most likely to give us a problem when adaptations are not reset on the 01M transmission is the 2-3. Most-common symptoms are bind-up or flare during the shift.

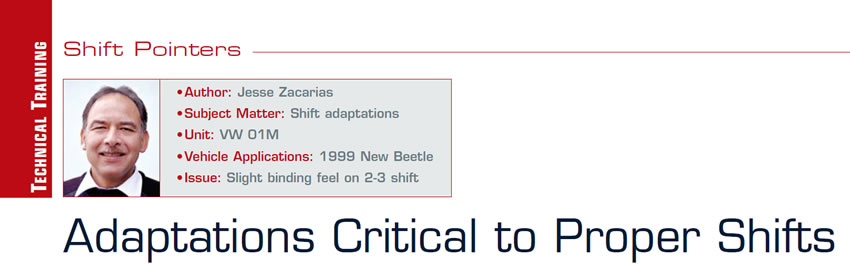

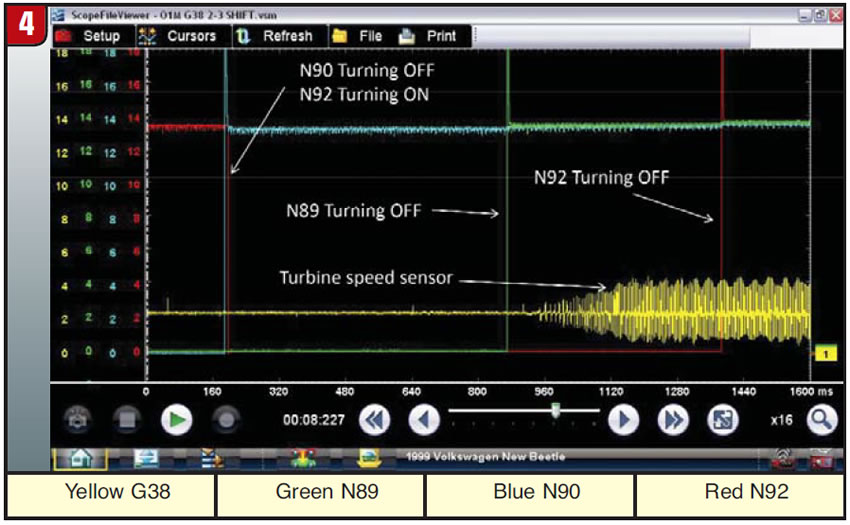

Let’s start by explaining what takes place during a 2-3 shift in the 01M, using the ’98-and-up model. Figure 1 shows the voltage readings obtained by back-probing each solenoid at the TCM; we are reading voltage drop in reference to battery ground.

When a solenoid reads battery voltage it means the solenoid is OFF, and when it reads less than 1 volt it is ON. To accomplish the 2-3 shift, the B2 clutches have to be released while the K3 clutches are being applied. In second gear, shift solenoid N88 (#1) is OFF and shift solenoids N89 (#2) and N90 (#3) are both ON. This shift-solenoid state allows the K1 and B2 clutches to be applied. If the B2 clutches are released too soon we get a 2-3 flare. On the other hand, if the K3 clutches are applied too soon we get a 2-3 bind. The shift timing is controlled by the transmission control module (TCM), taking into consideration its learned adaptation settings.

The 2-3 shift is initiated with the N90 (#3) (green) turned OFF and the N92 (#5) (blue) turned ON simultaneously (Figure 1).

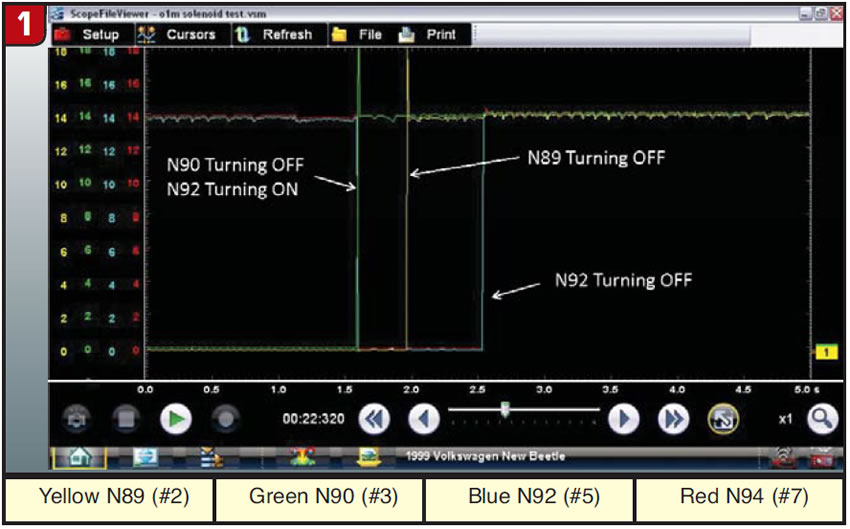

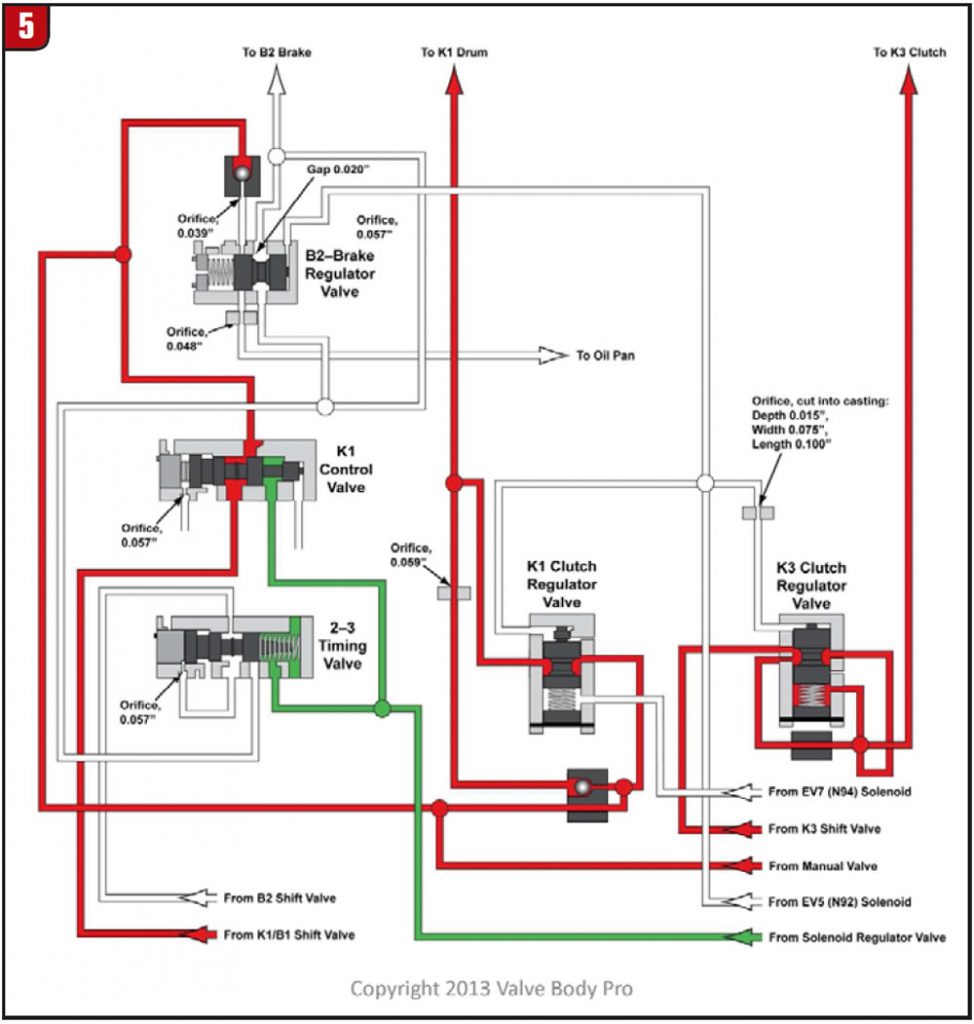

Turning OFF N90 allows the K3 shift valve to send main line pressure to the K3 clutches, but because N92 is turned ON the K3-clutch regulator valve blocks the fluid from reaching the K3 clutches (Figure 2). The N92 pressure (light blue in Figure 2) has to go through an orifice before getting to the K3-clutch regulator valve, which means there is a slight delay in K3 apply pressure coming from turning OFF solenoid N90. This slight delay allows the fluid coming from the K3 shift valve to pre-fill the K3-clutch circuit before the N92 fluid closes the path by stroking the K3-clutch regulator valve, thus serving as the servo phase of the shift.

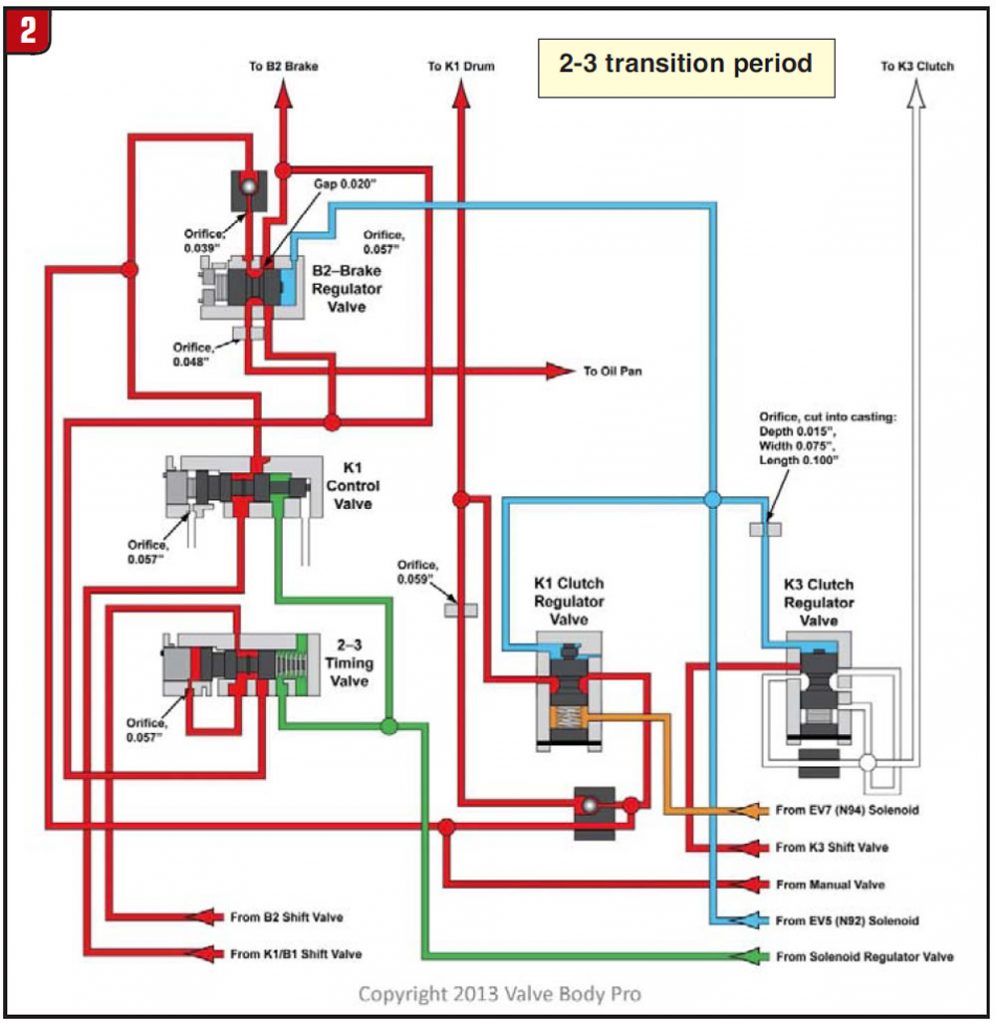

At the same time the engine computer reduces engine torque and the TCM reduces transmission main line pressure (Figure 3).

For the next phase of the 2-3 shift, the N89 (yellow in Figure 1, green in Figure 4) is turned OFF. That releases the B2 clutches and causes the sun-gear shell to start turning, producing a turbine-speed (G38) signal to be sent to the PCM (Figure 4).

When the turbine-speed signal reaches a certain frequency shift solenoid N92 (blue in Figure 1, red in Figure 4) is tuned OFF, allowing main line pressure to apply the K3 clutches (Figure 5), and engine torque is resumed.

This stage of the shift is when the TCM adaptations play an important part. The TCM bases the time needed to release the B2 clutches and apply the K3 clutches on its learned adaptation setting. If we change the clearance on either the B2 or K3 clutch or alter the line pressure, we have affected the timing required to apply or release these clutches and have changed the basis for the learned adaptations. Most technicians do not reset the adaptations before driving the vehicle after a repair or do not wait for the transmission to reach operating temperature. When they feel a shift flare or bind-up they are too quick to condemn the transmission when all it needs is to have the adaptations reset.

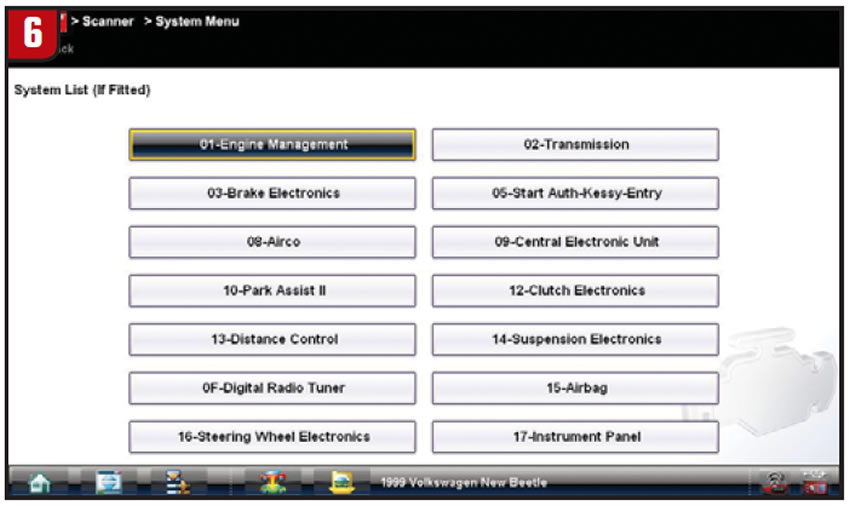

Resetting the adaptations requires a capable scan tool. Snap-on’s Scanner is capable if you use the 13.4 and later version. Here are the steps. After identifying the vehicle, establish communication with the engine module.

Select “Engine Management” (Figure 6).

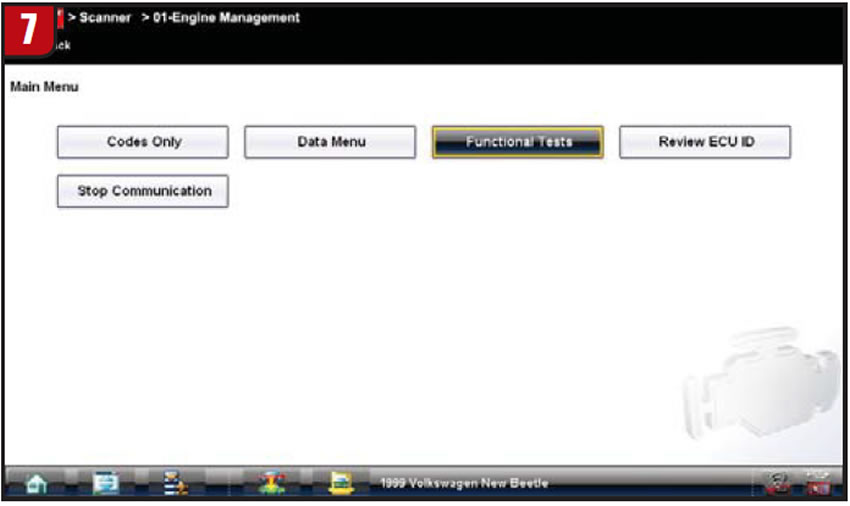

Select “Functional Tests” (Figure 7)

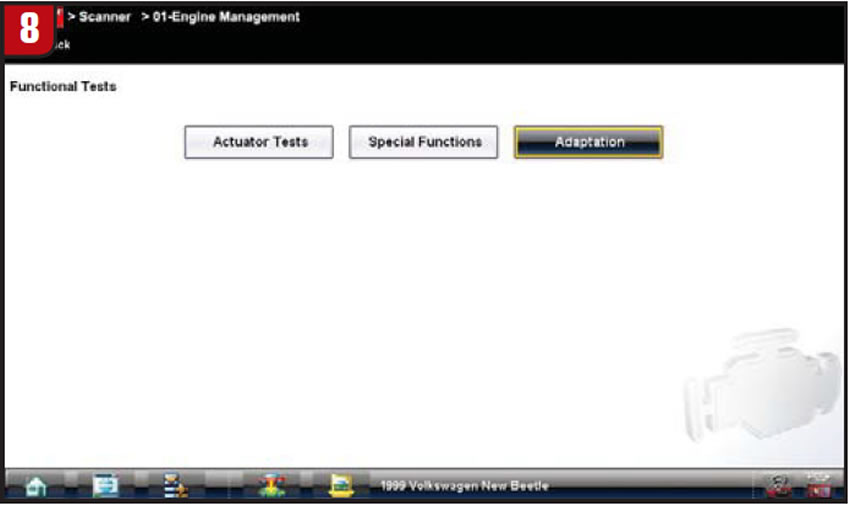

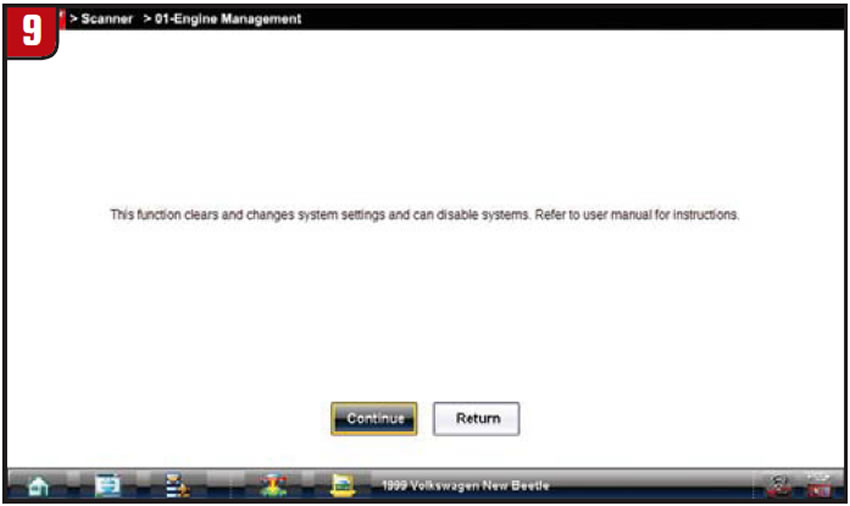

Select “Adaptation” (Figure 8). You will be asked to confirm that you want to change the adaptations. If so select “Continue” (Figure 9).

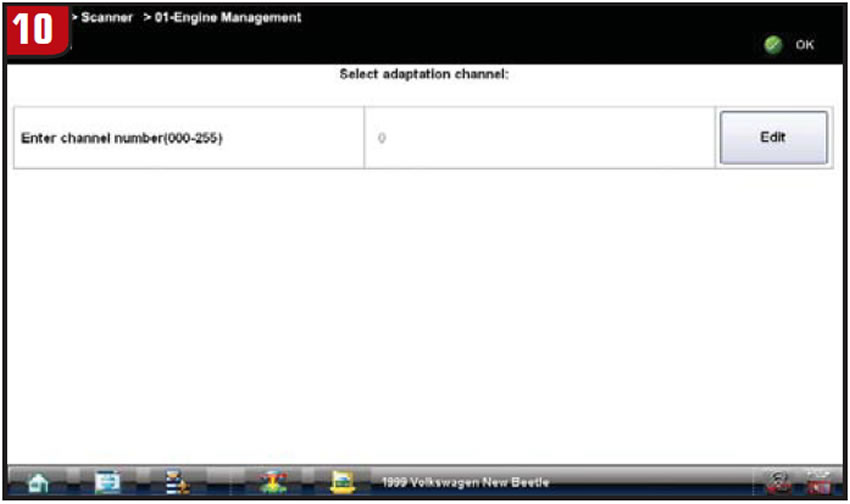

Make sure that a 0 value is entered in the channel (Figure 10). If so select OK.

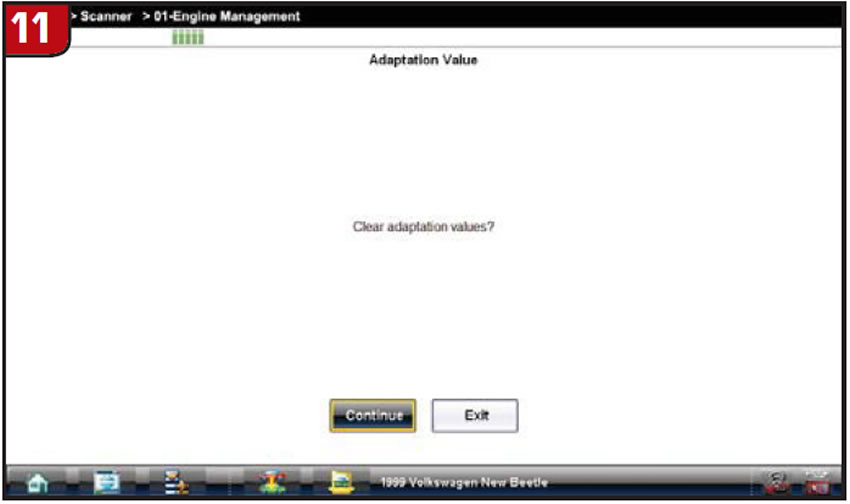

Select Continue (Figure 11)

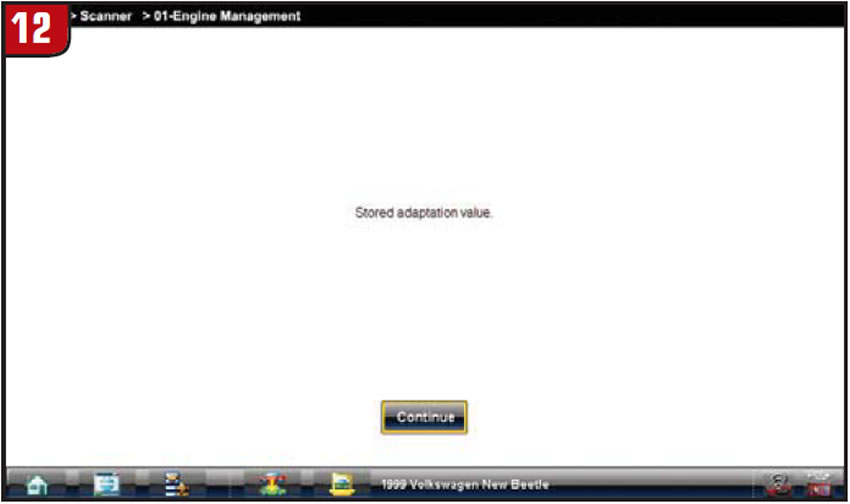

Select Continue (Figure 12)

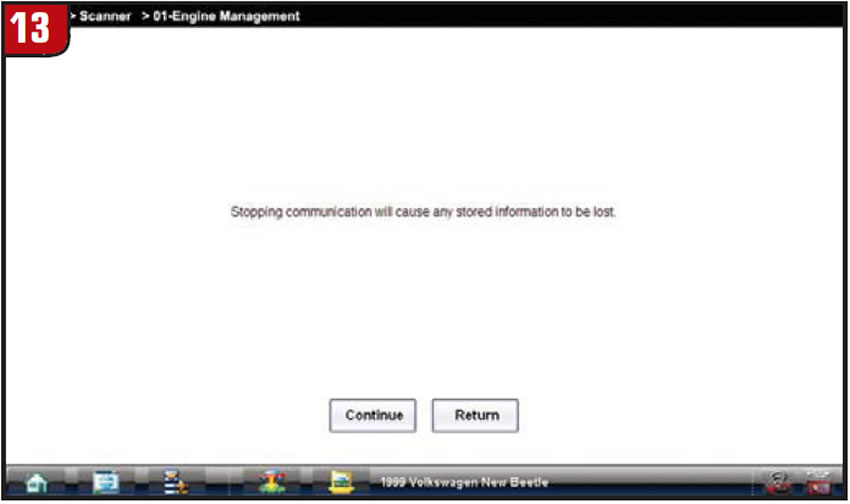

Do not forget to stop communication after you are finished (Figure 13). You should end up with the screen in step 1.

Now you need to drive the vehicle so it can learn the new adaptations. The transmission must be at operating temperature or the adaptations will not be learned. With 25% throttle drive the vehicle to obtain shifts 1-4. When 4th is obtained, bring the vehicle to a stop in less than 1 minute. Repeat this about five times. One word of caution here: Do not accelerate hard during the adaptation relearning, as the ECM will cut the fuel and the engine will not accelerate well until you back off the throttle.

After the shifts have been adapted, you will need to adapt the N-D and N-R initial engagements by doing five N-D engagements in the following manner: Place the vehicle in Neutral, then in Drive; wait five seconds, then place in Neutral. Wait five seconds and then repeat the procedure four to five times. Then do the same for Reverse, following the same procedure.

Resetting the adaptations is part of the job anytime a repair has been done to the transmission or the TCM or ECM has been replaced or re-flashed. This will contribute to a properly shifting transmission.

Jesse Zacarias is the owner of Elec-Tran Diagnostics (www.electrandiagnostics.com) in Gilroy, Calif., and part of the research-and-development department at Valve Body Pros.